What is Aluminium Veneer?

Aluminium veneer is a thin sheet of aluminum that is used as a decorative and protective surface in buildings and design projects. It combines the strength of aluminum with a lightweight structure, making it ideal for facades, ceilings, and wall cladding. Because of its durability and modern appearance, aluminium veneer is widely used in architecture, interior decoration, and commercial projects.

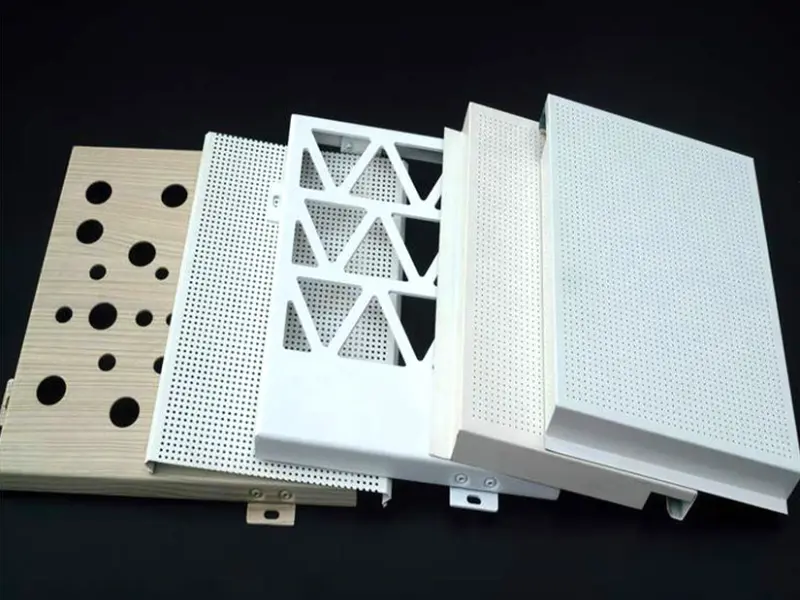

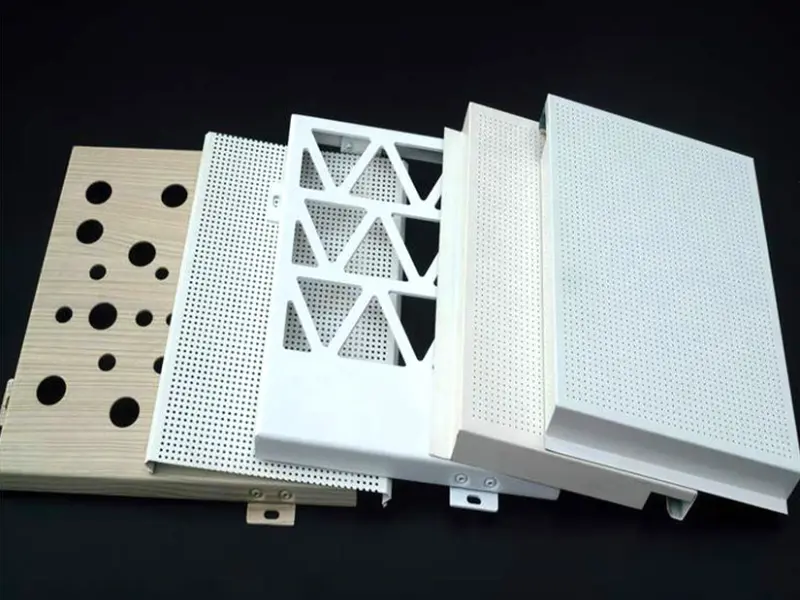

Classification of Aluminium Veneer

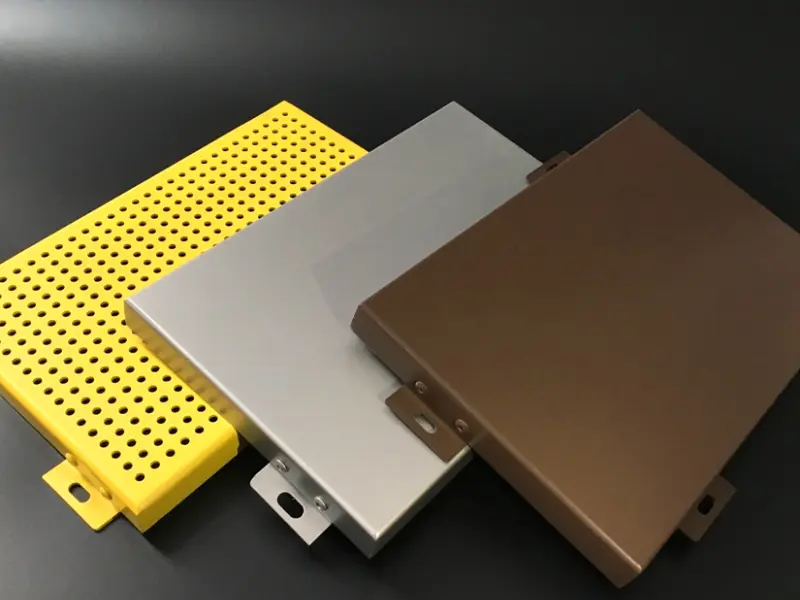

Aluminum veneer can be classified by surface finish, design style, and application.

| Classification Type | Description | Typical Use |

|---|---|---|

| Solid Aluminium Veneer | Flat panels without patterns | Building facades, ceilings |

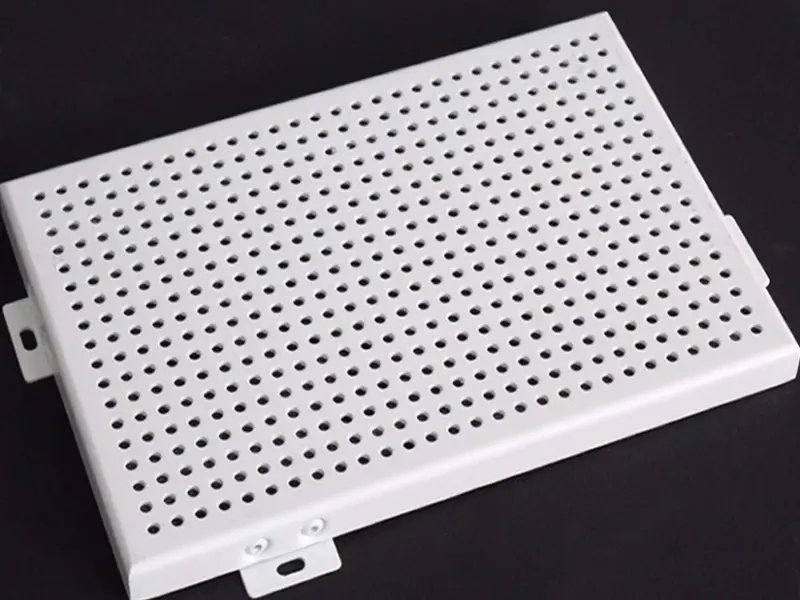

| Perforated Veneer | Holes or patterns for ventilation and design | Ceilings, acoustic walls |

| Curved Veneer | Bent or shaped panels | Columns, special building shapes |

| Wood Grain Veneer | Coated with wood texture | Interior decoration, furniture projects |

| Stone Imitation Veneer | Surface painted like marble or granite | Luxury interior and exterior decoration |

Thickness Options

Aluminum veneer thickness varies depending on its use.

| Thickness (mm) | Application Example |

|---|---|

| 1.5 mm | Interior wall panels, decorative ceilings |

| 2.0 mm | Indoor partitions, lightweight facades |

| 2.5 mm | Outdoor facades, columns, shop signs |

| 3.0 mm | High-rise building exteriors, structural uses |

| 4.0 mm+ | Heavy-duty cladding, public infrastructure |

Aluminium Alloys for Veneer

Common alloys are selected for strength, corrosion resistance, and processing quality.

| Alloy | Properties | Application |

|---|---|---|

| 1100 | High corrosion resistance, soft | Interior decorative panels |

| 3003 | Good corrosion resistance, formable | General building cladding |

| 5052 | High strength, weather resistance | Outdoor architectural projects |

| 6061 | Strong, durable, excellent machinability | Industrial and commercial uses |

Surface Finishes

Aluminum veneer surfaces can be coated in different styles:

- PVDF coating – excellent weather resistance, lasts 20+ years

- Powder coating – strong and eco-friendly finish

- Wood grain transfer – natural wooden look with durability

- Stone texture finish – granite or marble imitation

- Brushed or anodized finish – metallic modern look

Packaging

Proper packaging ensures panels arrive in perfect condition:

- Protective PE film on surface

- Foam or paper layer between sheets

- Wooden pallets for bulk shipping

- Custom packing for large projects

Applications

Aluminum veneer is used in many industries because of its durability and aesthetic appeal.

- Building facades – lightweight, modern, weather-resistant cladding

- Interior walls and ceilings – decorative and fire-resistant panels

- Columns and curved structures – custom-shaped designs

- Transportation hubs – airports, train stations, bus terminals

- Commercial buildings – shopping malls, office towers, hotels

- Signage and branding – shop fronts, advertising panels

- Public infrastructure – stadiums, exhibition halls, museums

Advantages of Aluminum Veneer

- Lightweight but strong

- Long service life with anti-corrosion coating

- Customizable in size, shape, and color

- Easy installation with fixing systems

- Fire-resistant and weatherproof

- Recyclable and eco-friendly material

Common Sizes and Specifications

| Size (mm) | Thickness (mm) | Alloy | Finish Options | Application Example |

|---|---|---|---|---|

| 600 × 600 | 1.5 – 2.0 | 1100 | PVDF, Powder Coated | Interior ceilings |

| 1220 × 2440 | 2.0 – 3.0 | 3003 | PVDF, Anodized | Building facades |

| 1500 × 3000 | 2.5 – 4.0 | 5052 | PVDF, Wood Grain, Stone | Outdoor walls, columns |

| Custom sizes | 1.5 – 5.0 | 1100/3003/5052/6061 | All finishes | Special projects, OEM order |

Why Choose Aluminum Veneer?

Aluminum veneer is the right choice for architects, designers, and builders who want:

- A modern and stylish appearance

- Strong material with long life span

- Cost-effective solution compared to natural stone or wood

- Flexibility in design and color matching

- Eco-friendly construction materials

Customization Options

- Thickness: Choose from thin veneers for flexibility or thick veneers for rigidity.

- Shapes: Custom cuts, curves, and perforations for unique designs.

- Finishes:

- Anodized: Durable, corrosion-resistant, and available in metallic colors.

- PVDF Coated: Weather-resistant and ideal for exteriors.

- Wood Grain: Mimics natural wood for aesthetic appeal.

- Sizes: Tailored dimensions to fit specific project requirements.

Installation and Maintenance

- Installation:

- Easily mounted using adhesives, mechanical fasteners, or clip systems.

- Suitable for DIY projects or professional installations.

- Maintenance:

- Clean with mild soap and water; avoid abrasive chemicals.

- Requires minimal upkeep due to corrosion resistance.

Why Choose Aluminum Veneer?

Safety: Fire-resistant and non-toxic.

Versatility: Adapts to various architectural and design needs.

Cost-Effective: Affordable compared to solid metals or natural materials.

Sustainability: Recyclable and energy-efficient production process.

What is Aluminium Veneer?

Aluminium veneer is made by processing aluminum alloy plates through cutting, bending, surface coating, and sometimes perforation. The result is a flat or shaped panel that is resistant to corrosion and weather conditions. Unlike composite panels, aluminum veneer is a solid aluminum sheet, usually coated with PVDF or powder paint for extra protection.

Leave a Comment

You must be logged in to post a comment.