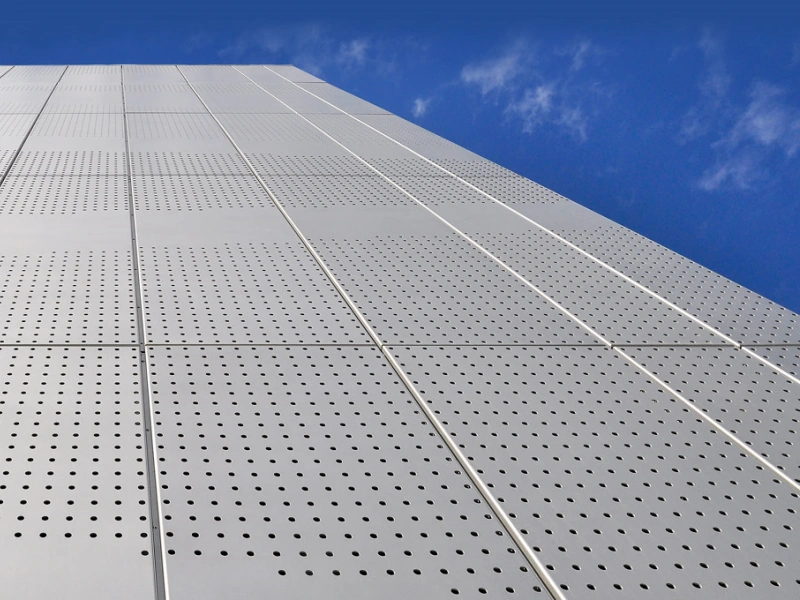

What Are Aluminium Perforated Panels?

Aluminium perforated panels are precision-engineered metal sheets with uniform hole patterns, offering:

Architectural aesthetics with functional airflow

Lightweight durability (50% lighter than steel)

Custom hole designs (round, square, decorative)

Technical Specifications

| Parameter | Specification |

|---|---|

| Material | 1100, 3003, 5052, 6061 Aluminum |

| Thickness | 0.5mm-6.0mm (±0.05mm) |

| Hole Size | 1mm-50mm diameter |

| Open Area | 15%-75% (customizable) |

| Panel Size | 1220x2440mm (standard) |

5 Key Benefits

1. Ventilation & Light Control

- Natural airflow management

- Sunlight filtration (30%-90% shading)

2. Structural Strength

- Maintains rigidity despite perforations

- 3x more impact-resistant than acrylic

3. Design Flexibility

- 50+ standard patterns

- Custom logos/artistic designs

4. Low Maintenance

- Corrosion-resistant (salt spray 1000+ hrs)

- Easy cleaning with water spray

5. Sustainability

- 100% recyclable material

- Reduces HVAC loads through natural cooling

Common Applications

1. Architectural

- Facade cladding (ventilated rain screens)

- Ceiling systems (acoustic control)

- Sunshades (UV protection)

2. Industrial

- Machine guards (30%-50% open area)

- Filtration screens (micrometer holes)

- Conveyor belts (food-grade 3003 alloy)

3. Interior Design

- Room dividers (decorative patterns)

- Retail displays (branded perforations)

- Art installations (laser-cut designs)

Alloy Comparison Guide

| Alloy | Best For |

|---|---|

| 1100 | Decorative indoor panels |

| 3003 | General outdoor cladding |

| 5052 | Marine/coastal environments |

| 6061 | Structural applications |

Fabrication Options

1. Hole Patterns

- Round: Most common (best airflow)

- Square: Modern aesthetic

- Hexagonal: Honeycomb visual

2. Finishing

- Anodized: Colorfast (20+ years)

- Powder-coated: 200+ RAL colors

- Mill finish: Natural metallic look

Why Choose Our Perforated Panels?

In-house CNC punching (0.1mm precision)

ISO 9001 certified production

3D modeling support for custom designs

Global shipping with edge protection

Frequently Asked Questions

1. How is open area percentage calculated?

(Total hole area ÷ Panel area) x 100

2. Minimum bending radius?

3x material thickness (e.g., 6mm for 2mm sheet)

3. Can panels be curved?

Yes – Pre-curving available up to 180°

4. Lead time for custom designs?

7-10 days for samples, 15-20 days for bulk

Keywords:

- aluminium perforated panel

- perforated metal sheets supplier

- architectural perforated aluminum

- decorative metal screen panels

- buy perforated aluminium sheets

- aluminum ceiling panels price

- worthwill perforated metal

- custom hole pattern aluminum

Leave a Comment

You must be logged in to post a comment.