Punched Metal Sheets

- Home

- Punched Metal Sheets

Punched Metal Sheets

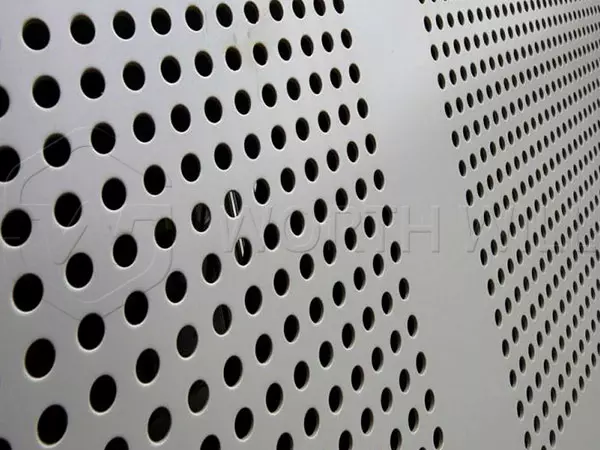

Punched metal sheets are an essential component in the construction industry. They are widely for use in architectural designs, facade cladding, industrial applications, and decorative purposes. Depending on the application, punched metal sheets are crafted from different materials including aluminum, brass, copper, stainless steel, and carbon steel. Punched metal sheets come in various sizes, shapes, and patterns with a wide range of hole sizes.

-

Free Samples

Punched Aluminum Sheet & Plate -

Factory Price

Manufacturer & Supplier

Punching Machine

Punching machines have use to create punched aluminum sheets.

The machine provides accurate and consistent stamping, ensuring perfect perforations.

Punched Aluminum sheets can have customization to meet the unique requirements of each client, including hole patterns and spacing.

If you have needs about the machine or products, please get in touch with us as soon as possible.

Application

In terms of applications, due to their strength and durability, punched sheets can offer excellent protection against weather elements and ventilation. In addition, metal sheets can also be used for privacy screening, providing an elegant yet practical solution for any outdoor area.

Punched aluminum sheets are also for use in industrial applications, where they serve as a protective layer for machines and equipment.

- Used to create heat exchange surfaces for heat exchangers, radiators, and condensers.

- This is due to the fact that the holes in the punched aluminum sheets allow for better circulation of air or fluid, which is essential for heat exchange.

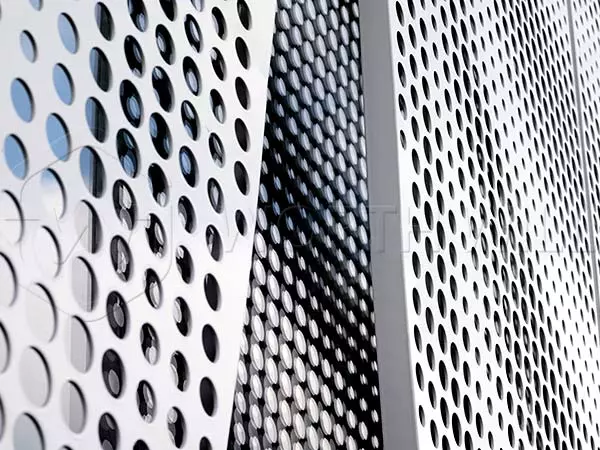

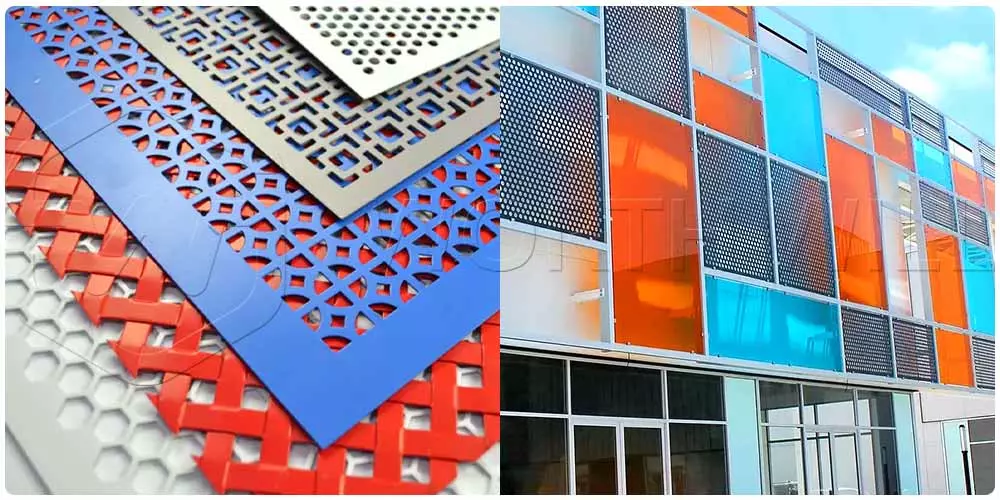

- The unique hole patterns and shapes of the punched aluminum sheets create a visual aesthetic, making them ideal for architectural designs.

- Punched metal sheets can befor use in both interior and exterior décor, adding a touch of sophistication to any space.

What Is Punched Metal Sheets?

Their strength and durability make them ideal for both practical and decorative purposes. With the ability to customize punched metal sheets to meet individual client needs, they offer endless possibilities for innovative and contemporary design solutions.

Aluminum punched plates also offer an aesthetically pleasing solution for architectural designs. The pattern of the holes can be customized to create a unique visual effect. Whether used as cladding for an entire building or a small decorative accent, punched metal plates can add a touch of elegance to any design.

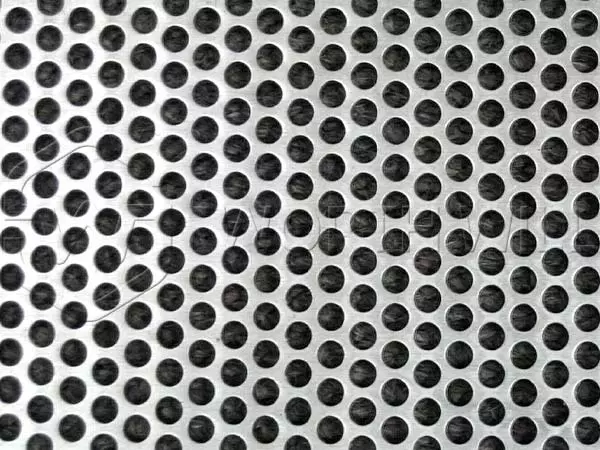

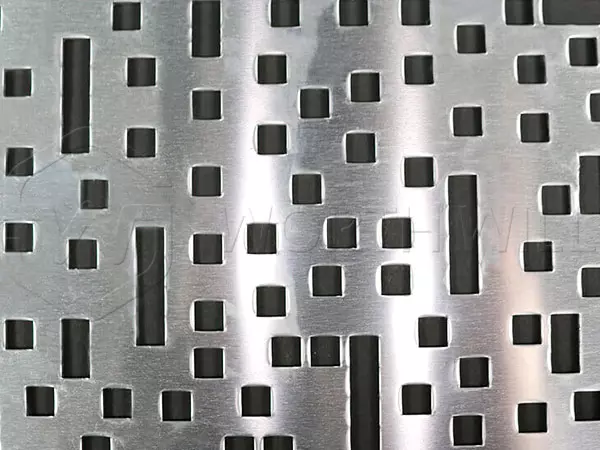

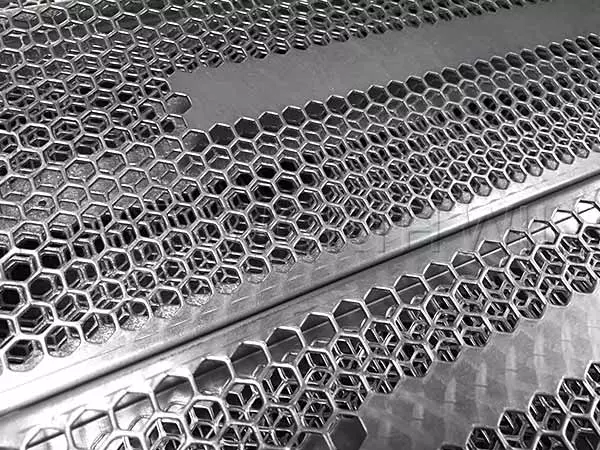

Punched aluminum sheet is a type of sheet metal that has holes or perforations stamped into it using a punching machine.

Punched aluminum sheets are commonly for use in architectural designs, cladding, and decorative applications.

They can also be in filters, ventilation systems, and machine guards.

The holes can be circular, rectangular, oval, or any other shape, and can be spaced out in a regular or irregular pattern.

Advantages

One of the primary advantages of using punched aluminum sheets is that they offer improved ventilation and airflow compared to solid metal sheets. This is particularly important in applications such as air filtration systems, where proper ventilation is essential.

What We Can Do?

Punched aluminum sheets can be customized to meet specific project requirements. The size and shape of the holes, as well as their spacing and pattern. It is suit individual needs. This allows for a high degree of flexibility in design and allows architects and designers to create unique and intricate perforated metal designs.

Additionally, punched aluminum sheets offer a lightweight and cost-effective alternative to solid metal sheets. They are easy to install and maintain, making them ideal for use in a variety of architectural and decorative applications.

The sheets offer a range of benefits and are a popular choice for architects, designers, and engineers alike. From improved ventilation and airflow to customizable designs, punched aluminum sheets are a versatile and efficient solution for a wide range of applications.