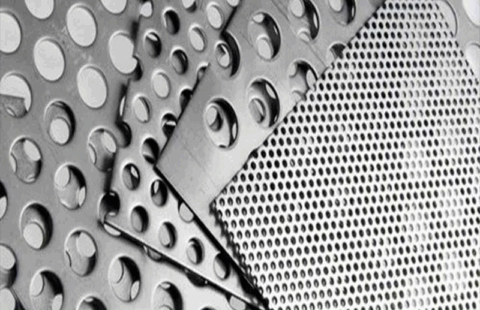

Perforated Aluminum Sheet Cut to Size

Introduction: The Convenience of “Cut to Size” Perforated Aluminium

In the world of materials, perforated aluminum sheet is already a highly versatile product, known for its lightweight nature, excellent corrosion resistance, and wide range of functional and aesthetic uses. However, its utility is significantly enhanced when it comes as a perforated aluminium sheet cut to size. This means instead of receiving large, standard sheets that then need further trimming, you get precisely the dimensions required for your specific project requirements.

This seemingly simple service offers immense benefits in terms of efficiency, waste reduction, and ensuring a perfect fit for any application. Whether for architectural facades, industrial filtration, or decorative panels, getting perforated aluminium precisely cut to size streamlines processes and guarantees professional results.

Understanding “Cut to Size” Perforated Aluminium

The term “cut to size” in the context of perforated aluminium sheet refers to the service where suppliers provide the material in custom dimensions tailored to a client’s exact specifications. Instead of buying a full 4’x8′ or 4’x10′ sheet and cutting it yourself, you provide the length and width you need, and the supplier delivers the perforated aluminium sheet in those precise measurements.

This approach addresses common challenges associated with standard sheet sizes:

- Minimizing Waste: Buying oversized sheets often results in offcuts and scrap material, which can be costly and environmentally unfriendly. Cut to size eliminates this waste.

- Saving Time: On-site cutting of perforated aluminium can be time-consuming, labor-intensive, and requires specialized tools. Pre-cut sheets arrive ready for installation.

- Ensuring Accuracy: Professional cutting services use advanced machinery to achieve high precision cutting, ensuring that every piece fits perfectly, reducing errors and rework.

- Reducing Labor Costs: Less on-site fabrication means fewer labor hours spent on cutting and finishing.

Essentially, perforated aluminium sheet cut to size simplifies your supply chain and fabrication process, making projects more manageable and cost-effective.

The Process of Cutting Perforated Aluminium

Achieving precision cutting on perforated aluminium sheet requires specialized equipment and expertise. Different cutting methods are employed depending on the thickness of the aluminium, the complexity of the desired shape, and the required finish quality.

- Shearing: This is a common and efficient method for straight-line cuts on perforated aluminium sheets. Large hydraulic shears use sharp blades to cut the metal quickly and cleanly. It’s ideal for producing rectangular or square pieces with high accuracy.

- Laser Cutting: For intricate shapes, complex designs, or very precise cuts, laser cutting is often used. A high-powered laser beam melts and vaporizes the aluminium, creating a very fine, clean cut edge with minimal heat distortion. This method is excellent for custom hole patterns or unique panel shapes.

- Waterjet Cutting: This method uses a high-pressure stream of water mixed with abrasive particles to cut through the aluminium. Waterjet cutting is particularly good for thicker perforated aluminium sheet, sensitive materials that cannot tolerate heat (preventing material changes), or when extremely complex shapes and a very smooth edge finish are required.

- Punching/Stamping: While primarily used for creating the perforations themselves, punching can also be used for cutting specific shapes or notches on the edges of perforated aluminium sheet as part of a continuous process.

Regardless of the method, the goal is always to deliver perforated aluminium sheet cut to size with clean edges, accurate dimensions, and without damaging the existing perforations or the integrity of the aluminium itself.

Key Advantages of Custom Cut Perforated Aluminium

Opting for perforated aluminium sheet cut to size brings a multitude of benefits to any project:

- Perfect Fit, Every Time: The most significant advantage is receiving materials that perfectly match your project requirements, eliminating the need for adjustments on-site.

- Reduced Material Waste: By ordering only what you need, you significantly cut down on scrap material, leading to cost-effective solutions and a more sustainable approach.

- Enhanced Project Efficiency: Pre-cut sheets mean faster assembly and installation times, reducing labor costs and accelerating project completion.

- Superior Edge Quality: Professional cutting equipment provides clean, burr-free edges, enhancing safety and the overall aesthetic of the finished product.

- Lower Production Costs: While the per-unit cost of a cut to size piece might seem higher, the overall project cost is often reduced due to savings on material waste, labor, and disposal.

- Access to Complex Shapes: For unique or custom designs, precision cutting allows for intricate shapes that might be difficult or impossible to achieve with standard on-site tools.

- Consistent Quality: Fabricators with specialized equipment ensure consistent quality across all cut to size pieces, maintaining uniformity throughout your project.

Types and Specifications of Perforated Aluminium Sheet Cut to Size

| Feature | Description | Common Specifications / Options |

|---|---|---|

| Material Alloy | Specific aluminium alloy impacting strength, formability, corrosion resistance. | 3003 (general purpose), 5052 (marine/high strength), 6061 (structural) |

| Sheet Thickness | The gauge or thickness of the aluminium sheet before perforation. | From 0.020″ (0.5mm) up to 0.250″ (6.35mm) or more |

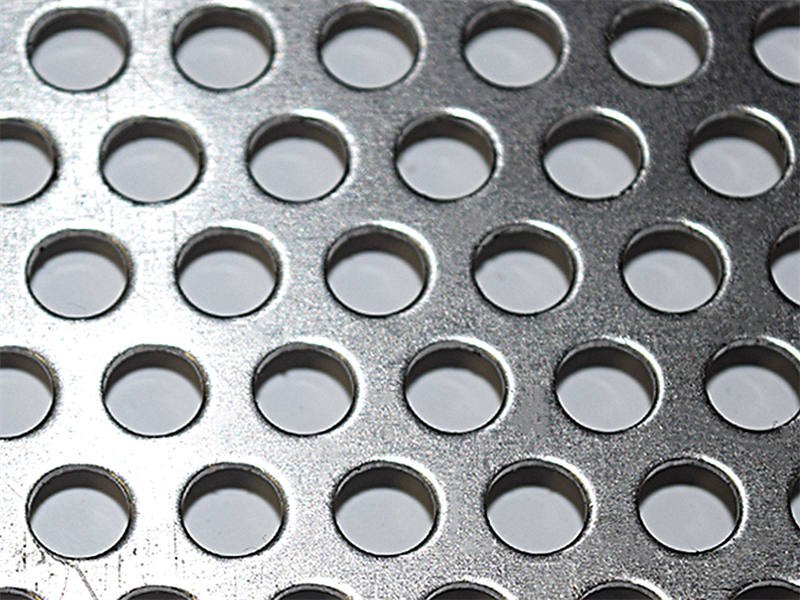

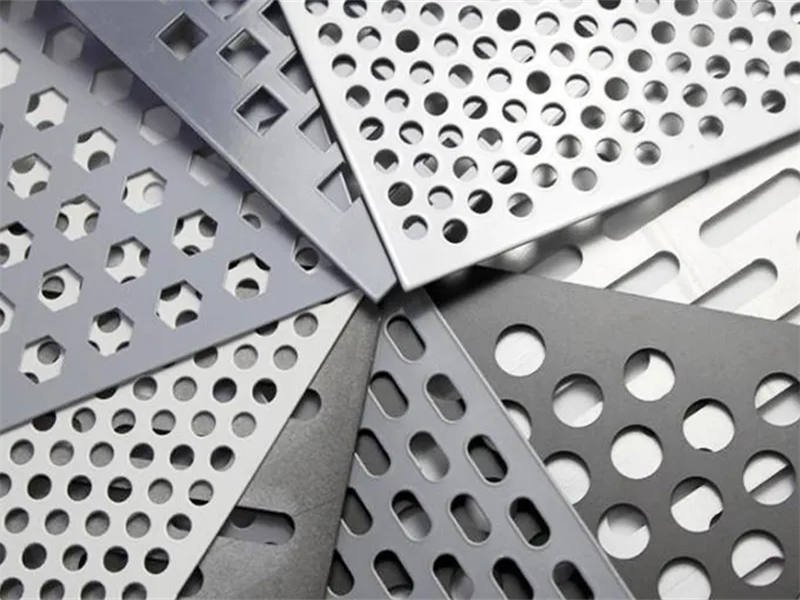

| Hole Shape | The geometry of the perforations. | Round, Square, Slotted, Hexagonal, Decorative, Custom |

| Hole Size | The diameter or dimension of the individual holes. | From 0.020″ (0.5mm) up to 2″ (50mm) or larger |

| Hole Pattern | The arrangement of holes (e.g., staggered vs. straight rows). | 60-degree staggered (most common), 90-degree straight, 45-degree staggered |

| Open Area (%) | The percentage of the sheet that is open space (holes). | Typically 20% to 60%, can range widely from 5% to 80% |

| Margins/Borders | Unperforated areas along the edges of the sheet. | Standard (equal on all sides), Custom (specific widths, unequal), No margins |

| Dimensions (L x W) | The precise length and width of the final cut to size sheet. | Any specific dimensions required by the customer |

| Surface Finish | Post-perforation treatment for aesthetics or added protection. | Mill Finish (raw), Anodized (clear/colors), Powder Coated (colors), Brushed |

This level of customization allows for an incredibly precise match to diverse functional and design requirements, making perforated aluminium sheet cut to size a highly adaptable material.

Versatile Applications of Perforated Aluminium Sheet Cut to Size

- Architectural and Building:

- Façade Cladding: Custom-sized panels for modern building exteriors.

- Sunshades and Louvers: Precision-cut for optimal light control and aesthetics.

- Ceiling Tiles and Wall Panels: Pre-cut for easy installation and acoustic dampening.

- Balustrade Infill Panels: Custom shapes and sizes for railings and staircases.

- Decorative Screens: Unique patterns and sizes for visual appeal and privacy.

- HVAC and Ventilation Systems:

- Air Diffusers and Grilles: Exact dimensions for efficient airflow in ducts and vents.

- Ventilation Panels: Custom cut for precise fit in equipment and rooms.

- Filtration and Screening:

- Custom Filter Media: Specific hole sizes and shapes for industrial and commercial filtration.

- Screens for Food Processing: Tailored to fit machinery and hygiene standards.

- Acoustic Control:

- Sound Barriers and Enclosures: Precisely cut panels to fit around noisy machinery or in auditoriums.

- Acoustic Wall and Ceiling Panels: Ready-to-install pieces for sound absorption.

- Industrial and Manufacturing:

- Machine Guards: Custom-fabricated to protect machinery and personnel.

- Conveyor Components: Specific sizes for various material handling systems.

- Work Benches and Shelving: Durable and lightweight components for industrial settings.

- Retail and Display:

- Retail Fixtures: Custom-cut panels for displays, shelving, and signage.

- Decorative Backings: Unique sizes for product displays and branding.

- Consumer Products:

- Appliance Components: Vents, grilles, or internal structures requiring specific cut-outs.

- Outdoor Furniture: Custom sizes for seats, tables, and decorative elements.

Why Choose Perforated Aluminium and “Cut to Size”?

However, it’s the “cut to size” service that truly unlocks the material’s full potential for modern fabrication. By eliminating the need for on-site cutting, it dramatically reduces material waste, saves valuable time, lowers labor costs, and ensures that every piece fits perfectly. This leads to a more streamlined workflow, higher quality finished products, and overall cost-effective project delivery. For any project, big or small, that requires perforated aluminium, opting for a cut to size service is a smart and practical decision that prioritizes precision, efficiency, and professional results.

Leave a Comment

You must be logged in to post a comment.