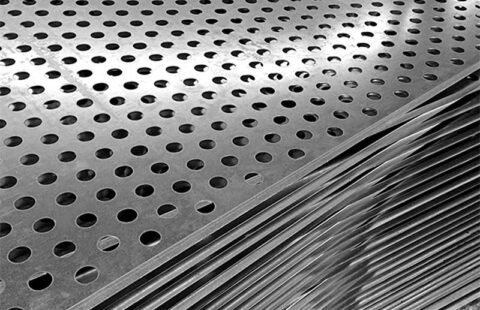

Perforated Aluminum Sheet 4×8

Perforated aluminum sheet 4×8 is a popular material in construction, design, and industrial applications. With a standard size of 4 feet by 8 feet, this sheet offers versatility, strength, and durability. It features multiple holes, allowing airflow, light, and sound control while maintaining structural integrity.

Types and Specifications of Perforated Aluminum Sheet 4×8

Perforated aluminum sheets come in various thicknesses, hole sizes, and patterns to meet diverse needs. The 4×8 size is a common standard that fits many projects. Here is a table featuring typical types and specifications:

| Type | Thickness (mm) | Hole Diameter (mm) | Pattern Type | Perforation Percentage | Common Uses |

|---|---|---|---|---|---|

| Fine Perforation | 0.5 – 0.8 | 1 – 3 | Round | 20% – 40% | Acoustic panels, decorative screens |

| Medium Perforation | 1.0 – 1.5 | 3 – 6 | Square | 30% – 50% | Ventilation panels, sunshades |

| Heavy Perforation | 1.6 – 2.5 | 6 – 10 | Hexagonal | 40% – 60% | Industrial filters, machine guards |

These specifications help you select the right sheet for your project’s technical and visual needs.

How to Use Perforated Aluminum Sheet 4×8

Using perforated aluminum sheets effectively includes these key steps:

- Measurement and Cutting:

- Measure your installation area carefully.

- Cut the sheet to the required size using shears or saws.

- Surface Preparation:

- Clean the area where the sheet will be applied to ensure adhesion.

- Apply primers if painting or coating will be done.

- Installation:

- Fix the sheet using bolts, screws, or welding according to the application.

- Use spacers if airflow or clearance is needed.

- Finishing:

- Paint or treat the sheet to protect it from corrosion.

- Choose powder coating for longer outdoor durability.

Applications of Perforated Aluminum Sheet 4×8

Perforated aluminum sheets of 4×8 size are used widely in many industries and decorative projects:

- Facade cladding for commercial buildings.

- Acoustic ceiling and wall panels.

- Sunshade louvers to reduce heat.

- Machine guards and safety screens.

- Air filters and ventilation grilles.

- Decorative partitions and screens.

- Exterior signage with backlighting effects.

Benefits of Perforated Aluminum Sheet 4×8

Using perforated aluminum sheets offers several advantages:

- Lightweight: Easy to transport and install.

- Durable: Resistant to rust, corrosion, and weather.

- Versatile: Suitable for both indoor and outdoor uses.

- Customizable: Many patterns and hole sizes available.

- Aesthetic: Enhances visual appeal with modern designs.

- Functional: Allows airflow, ventilation, and sound control.

Maintenance Tips for Perforated Aluminum Sheets

To maintain perforated aluminum sheets in good condition:

- Clean regularly with mild soap and water.

- Avoid abrasive tools that can scratch the surface.

- Inspect screws or bolts and tighten if needed.

- Repaint sheets exposed to harsh weather for prolonged life.

Fabrication Options

| Process | Compatibility | Notes |

|---|---|---|

| Cutting | Excellent | Shearing, laser, waterjet |

| Bending | Good | Minimum radius = 3x thickness |

| Welding | Fair | TIG welding recommended |

| Finishing | Excellent | Painting, powder coating, anodizing |

Installation Tips

✔ Use appropriate fasteners (aluminum or stainless steel)

✔ Allow for thermal expansion (1/4″ per 10 feet)

✔ Handle with gloves to prevent scratches

✔ Clean with mild detergent and soft cloth

Price Factors

| Factor | Price Impact |

|---|---|

| Thickness | Thicker = higher cost |

| Hole Pattern | Complex patterns = +20-50% |

| Alloy | 5052/6061 = +25% vs 1100 |

| Quantity | Volume discounts available |

| Finish | Powder coating = +30-40% |

*Average price: $150-$400 per sheet*

Benefits of 4×8 Sheets

- Standard Size: Fits most applications

- Easy Handling: Manageable weight and size

- Cost Effective: Competitive pricing

- Versatile: Multiple hole patterns available

- Durable: Long-lasting performance

FAQ

Q: Can 4×8 perforated sheets be cut to size?

A: Yes, most suppliers offer custom cutting services

Q: How are the sheets packaged for shipping?

A: Typically flat-packed with protective covering

Q: What’s the lead time for custom patterns?

A: Usually 2-4 weeks for production

Q: Are these sheets suitable for outdoor use?

A: Yes, especially 5052 and 6061 alloys

Leave a Comment

You must be logged in to post a comment.