Perforated Aluminium

- Home

- Perforated Aluminium

Perforated Aluminium

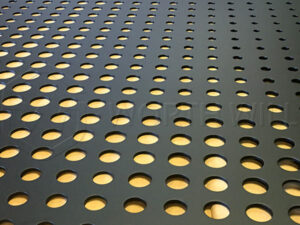

Perforated aluminium refers to aluminum sheets or panels that have been punched or stamped with a pattern of holes or other shapes. The holes can be of different sizes, shapes, and patterns, depending on the desired aesthetic or functional requirements.

-

Free Samples

Customized Service -

Factroy Price

Aluminum Facade

Customization:

For different size and shape of the perforations, we can help clients to customize and meet specific design and performance requirements.

- Applciation:

Perforated aluminum has wide application in architectural applications such as facades, ceilings, and sunscreens. As well as in industrial and commercial applications such as filters, screens, and vents.

- Features:

It has value for its durability, corrosion resistance, and lightweight properties.

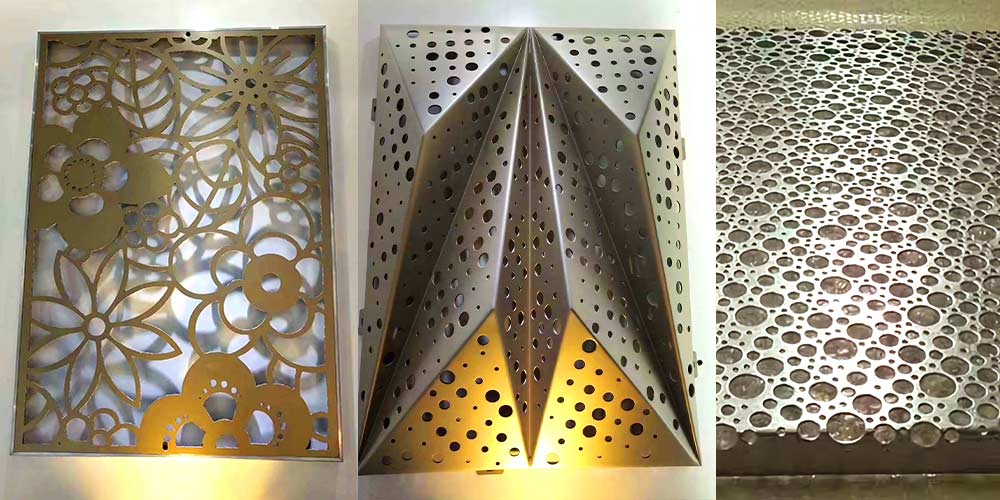

The perforations in the aluminum can be made using various techniques, including CNC punching, laser cutting, and stamping.

Types

Customization Size and Shapes

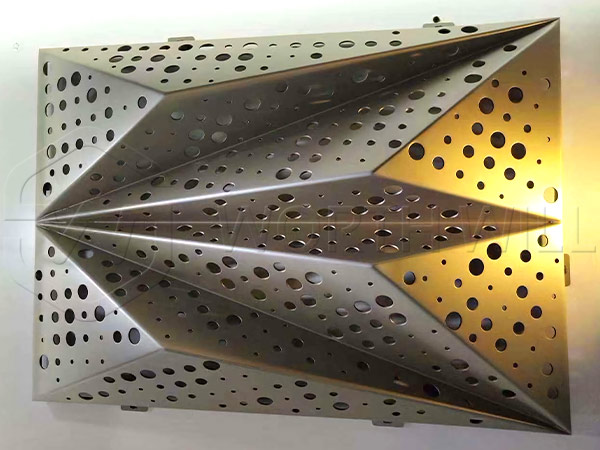

As a decorative or functional surface finish, the perforations can be of various sizes and shapes, according to different patterns depending on the desired effect.

Application

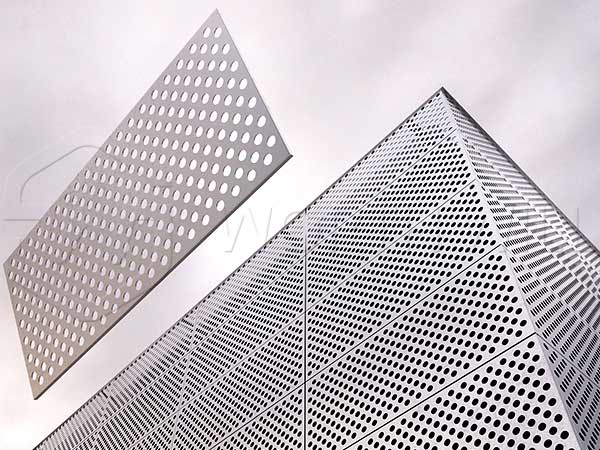

Perforated aluminium veneer is often in architectural applications such as building facades, interior walls, and ceilings. It provides an attractive and modern look while also serving functional purposes such as ventilation or sun shading.

Cutting Techniques

The perforations in the aluminum veneer can be made using different techniques, including CNC punching, laser cutting, and stamping. For the size and spacing of the perforations, we can customize to achieve the desired level of transparency, airflow, and shading.

Advantages

Compared with other decorative finishes, perforated aluminum veneer has many advantages, including its durability, corrosion resistance, and ease of maintenance. It is also lightweight, which make it easy to install and handle.

Perforated Aluminium Sheet

The perforated hole has many different sizes, shapes, and patterns, depending on customers’ functional requirements.

Application

In a wide range of applications, including architectural, industrial, and commercial projects. It has benefits about lightweight, corrosion-resistant, and durable properties. In addition, As ventilation grilles, acoustic panels, filters, and screens. Also as decorative elements in interior or exterior designs, such as wall cladding, sunscreens, and ceiling panels. The thickness of perforated aluminum sheet can vary depending on the application. Customers have different choices about coated or anodized to enhance its performance and appearance. In conclusion, perforated aluminum sheet is a versatile material. We can meet the needs of many different industries and applications.

Why is perforated aluminium so popular in Australia?

Perforated aluminum is popular in Australia for several reasons:

- Climate: Australia has a warm and sunny climate, and perforated aluminum is an excellent material for shading and ventilation systems. It allows natural light and air to pass through while reducing heat gain and providing shade.

- Aesthetics: Perforated aluminum is a popular choice for architectural projects in Australia due to its sleek, modern appearance.

- In building facades, sunscreens, and other applications to create a contemporary look.

- Durability: Aluminum is a durable material that can withstand the harsh Australian climate, including high winds, rain, and exposure to the sun. Perforated aluminum is resistant to corrosion, and it can last for many years with minimal maintenance.

- Sustainability: Aluminum is a sustainable material that is 100% recyclable, and perforated aluminum sheets. They have recycled indefinitely without losing quality. This makes it an environmentally friendly option for architects, builders, and designers in Australia who value sustainable building practices.

In short, perforated aluminum is popular in Australia due to its versatility, durability, and aesthetic appeal. Wide applciation in architectural, industrial, and commercial projects throughout the country.