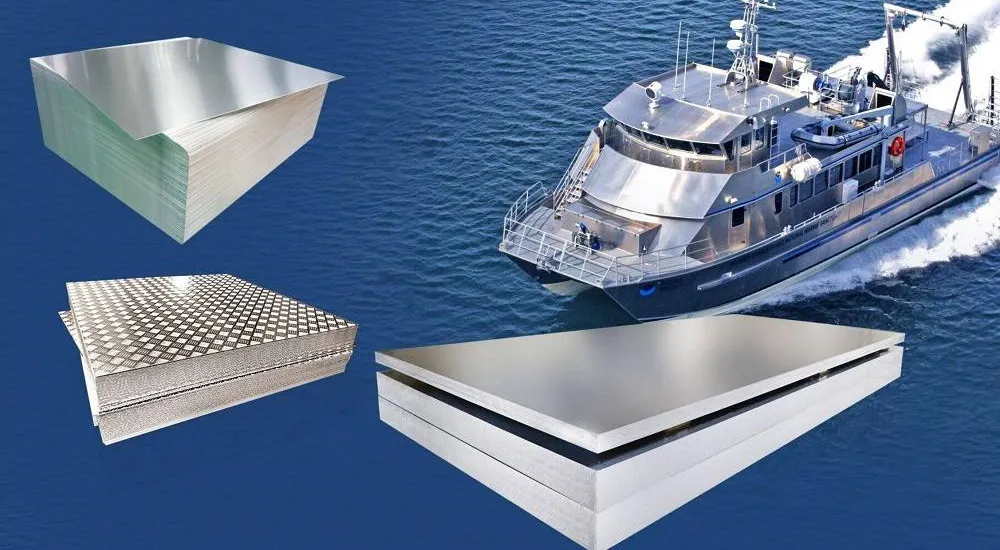

Marine aluminum sheets are specially engineered for shipbuilding and offshore applications, offering exceptional corrosion resistance, weldability, and strength-to-weight ratio. Made from premium 5000-series alloys like 5083 and 5052, these sheets withstand harsh saltwater environments while reducing vessel weight by 30-50% compared to steel.

Key Specifications

| Parameter | Details | Custom Options |

|---|---|---|

| Alloys | 5083, 5059, 5383, 5086 | Other marine grades |

| Temper | H111, H112, H116, H321 | Special tempers |

| Thickness | 3-50mm | Up to 100mm |

| Width | 300-2550mm | Custom widths |

| Certifications | DNV, ABS, BV, LR, CCS | Additional class certs |

| Surface Finish | Mill finish, brushed, anodized | Custom coatings |

Alloys of Marine Grade Aluminium Sheet

The choice of alloy depends on the specific application and required properties like strength, weldability, and formability.

- 5083 Aluminum Sheet and Plate: Highly regarded for its exceptional corrosion resistance and high strength, especially in the H116 and H321 tempers. 5083 marine grade aluminum is often used for structural components like hulls, decks, and superstructures of ships and large yachts. It maintains strength even at low temperatures, making it suitable for cryogenic applications onboard vessels.

- 5059 Aluminum: An even higher strength version of 5083, offering improved ballistic protection and corrosion resistance. Used in demanding marine applications.

- 5383 Aluminum: Another high-strength alloy, often used where weight reduction is critical without compromising structural integrity in aggressive marine environments.

- 5086 Aluminum: Similar properties to 5083, with good strength and excellent corrosion resistance. It is slightly less strong than 5083 but offers better formability.

- 5052 Aluminum: Provides good corrosion resistance in marine environments and excellent formability. 5052 H32 flat sheet marine grade is commonly used for less structural components such as fuel tanks, bulkheads, small boat hulls, and general sheet metal work on boats due to its ease of bending and welding.

Choosing the correct marine grade aluminum alloy ensures durability and safety at sea.

Why Choose Marine Grade Aluminum?

Saltwater corrosion resistance – Magnesium content prevents pitting

High strength – 5083 alloy offers 275-350 MPa yield strength

Lightweight – 2.7g/cm³ density reduces fuel consumption

Excellent weldability – No pre-heating required

Low maintenance – No painting needed vs. steel

Top Marine Applications

Shipbuilding Components

- Hull plating and superstructures

- Decking and bulkheads

- Cabin components

Offshore & Naval

- Oil rig walkways

- Patrol boat armor

- Floating docks

Yacht & Leisure

- Hulls for luxury yachts

- Fishing boat frames

- Marine railings

Alloy Comparison Guide

| Alloy | Key Feature | Best For |

|---|---|---|

| 5083 | Highest strength | Hull construction |

| 5059 | Improved weldability | Military vessels |

| 5383 | Enhanced fracture toughness | Ice-class ships |

| 5052 | Good formability | Interior panels |

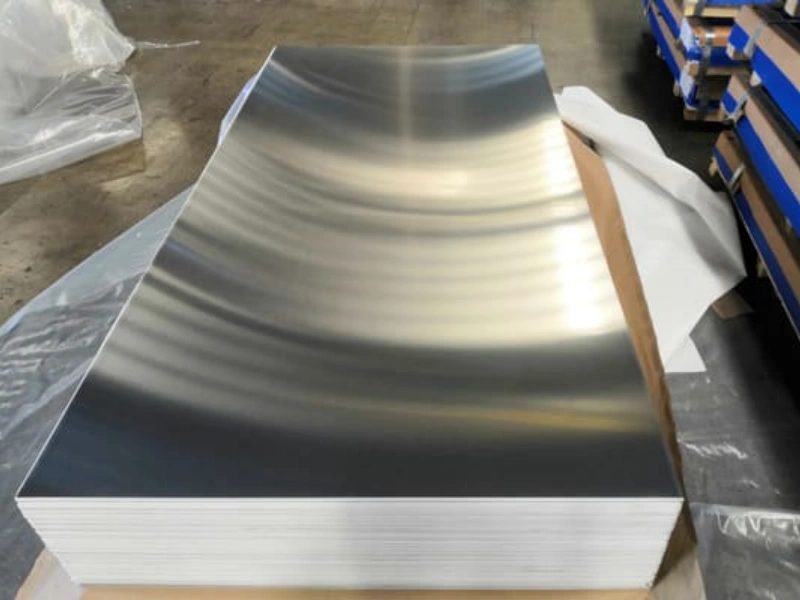

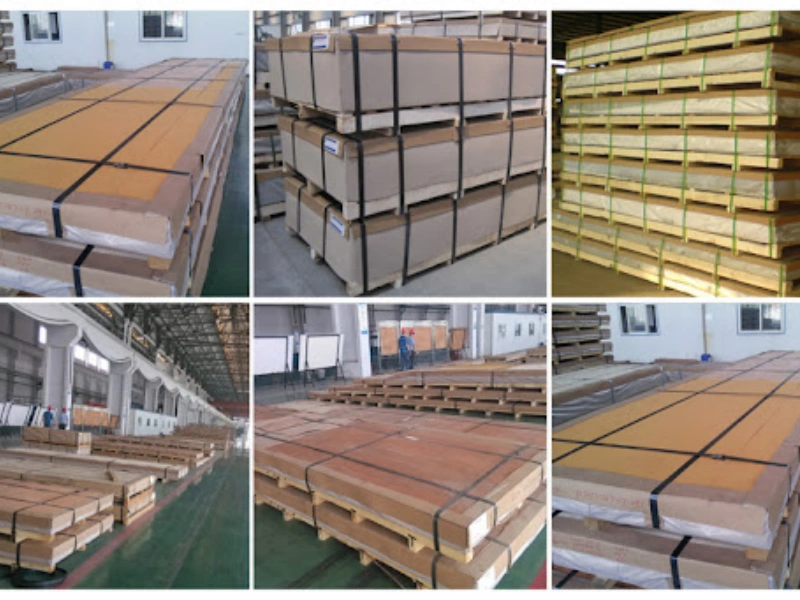

Marine Grade Aluminum Sheets for Sale

Our marine-grade aluminum sheets for sale are available in different sizes and finishes. We offer fast delivery and competitive pricing. Custom orders are welcome.

Common sizes include:

- 4ft x 8ft

- 5ft x 10ft

- Custom sizes upon request

The 5005 Marine Grade Aluminum Plate Sheet

5005 aluminum sheet is also used in marine applications, especially for decoration and non-structural parts. It offers good corrosion resistance and a smooth finish.

Alloys of Marine Grade Aluminium Sheet

Popular marine aluminum alloys include:

- 5083: Best strength and corrosion resistance

- 5059: Higher strength than 5083

- 5383: Improved welding performance

- 5086: Good strength and corrosion resistance

- 5005: Decorative applications

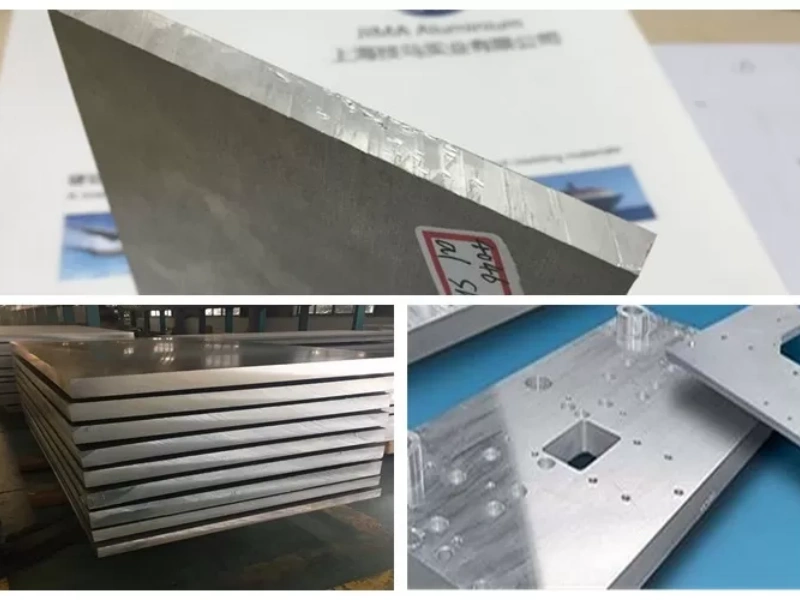

5083 Aluminum Sheet and Plate

5083 aluminum sheet and plate are widely used in marine structures due to their excellent performance:

- High strength after welding

- Excellent seawater corrosion resistance

- Suitable for hulls, decks, and tanks

Marine Grade Aluminum 5083 Price

The 5083 marine-grade aluminum price varies based on thickness, width, and surface finish.

Factors affecting the price:

- Alloy grade

- Order quantity

- Custom processing needs

For a fast and accurate quote, please contact us via WhatsApp at +8615736973771.

5052 H32 Flat Sheet Marine Grade

5052 H32 flat sheet is another option for marine applications. It offers:

- Good formability

- Corrosion resistance in seawater

- Cost-effective for small boats and interior parts

Use of Aluminum Sheets in the Marine Industry

Marine aluminum sheets are used in many areas, such as:

- Shipbuilding (hulls, decks)

- Yacht structures

- Fishing boats

- Oil platform modules

- Ramps and gangways

- Offshore wind towers

- Dock and harbor equipment

Certifications & Quality

DNV/GL certified for marine applications

ABS Type Approval for critical components

Third-party testing reports available

What Makes Aluminum “Marine Grade”?

Not all aluminum is suitable for use in saltwater. Marine grade aluminum specifically refers to certain aluminum alloys that have been developed and tested to resist corrosion, particularly in harsh marine environments. The most common marine grade aluminum alloys are from the 5000 series, which contain magnesium as the primary alloying element. Magnesium provides excellent resistance to corrosion from saltwater and other harsh chemicals often found in marine settings. Alloys like 5083 aluminum sheet, 5052 aluminum sheet, 5086 aluminum, 5059, and 5383 are widely recognized as marine grade.

Why Buy From Us?

Manufacturing Expertise

- 15+ years marine industry experience

- State-of-the-art rolling mills

- Precision cutting capabilities

Global Supply

- Competitive marine grade aluminum 5083 price

- Container load optimization

- Just-in-time delivery

Value-Added Services

- Plasma/laser cutting

- Heat treatment

- Protective packaging

Order Information

📞 WhatsApp: +86 15736973771

📧 Email: jane@worthwillau.com

Minimum Order: 1 ton (samples available)

Lead Time: 7-15 days for standard sizes

Frequently Asked Questions (FAQs)

Here are answers to common questions about marine aluminum:

What is the difference between aluminum and marine-grade aluminium?

Standard aluminum (like alloys from the 1xxx, 3xxx, or 6xxx series without specific treatments) can corrode quickly in saltwater, especially through pitting and crevice corrosion. Marine grade aluminum, primarily the 5xxx series (with magnesium), is specifically designed to resist these types of corrosion in harsh marine environments.

What aluminum is best for marine use?

For structural components of boats and ships exposed to saltwater, 5083 aluminum is generally considered the best due to its high strength and exceptional resistance to saltwater corrosion. 5052 aluminum is excellent for less structural parts like tanks and bulkheads where good formability is needed.

What is the difference between 6061 and 5052 aluminum for boats?

5052 aluminum (a 5xxx series alloy) has superior resistance to saltwater corrosion compared to 6061 aluminum (a 6xxx series alloy). While 6061 is stronger and more easily machined and welded, its corrosion resistance in saltwater is not as good as the 5xxx series. 6061 is better suited for freshwater applications or structural parts above the waterline, while 5052 is suitable for tanks and lighter structures, and 5083 is preferred for saltwater hulls and primary structures.

Is 6061 a marine-grade aluminum?

6061 aluminum is sometimes referred to as “marine-grade” because it is used in some marine applications, like boat frames, masts, and railings, especially in freshwater or areas not constantly immersed in saltwater. However, it is not considered the primary marine grade alloy for saltwater hull construction due to its lower resistance to crevice corrosion and pitting in continuous saltwater exposure compared to the 5xxx series alloys like 5052 or 5083. The 5xxx series are the true workhorses for saltwater immersed structures.

More Details from Customers Want to Learn

Q: What makes marine-grade aluminum different?

A: Contains 3-6% magnesium for superior saltwater resistance vs regular aluminum.

Q: Is 6061 suitable for marine use?

A: Not recommended – 5052/5083 are better as 6061 corrodes faster in seawater.

Q: How does 5052 compare to 5083?

A: 5083 is 50% stronger but 5052 is more formable for complex shapes.

Q: What thickness for boat hulls?

A: Typically 6-12mm depending on vessel size (consult naval architect).