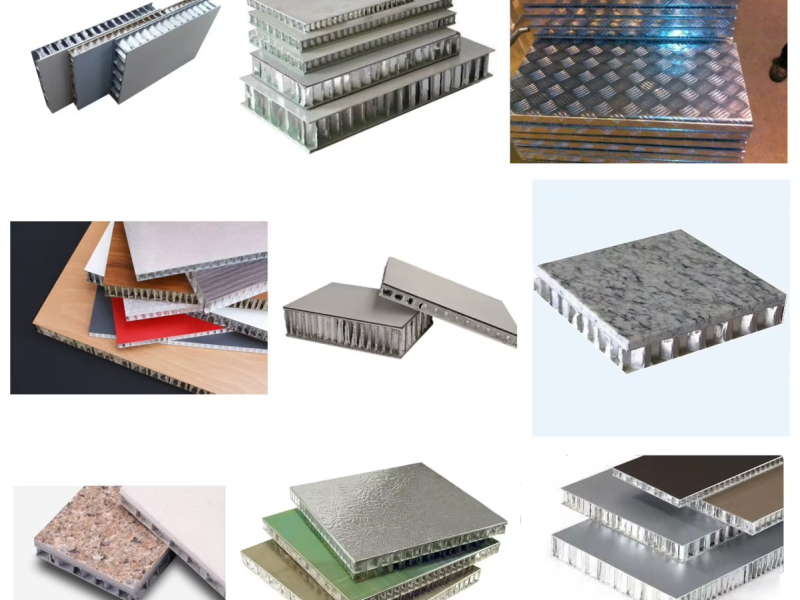

Extruded honeycomb panel consists of an aluminum core sandwiched between two aluminum sheets. They are known for:

- Lightweight Strength: Comparable to solid aluminum but much lighter.

- Superior Flatness: Perfect for architectural and industrial applications.

- Long Lifespan: Resistant to corrosion, fire, and impact.

These panels offer exceptional rigidity while being ultra-lightweight – up to 70% lighter than solid aluminum.

Specifications of Extruded Aluminum Honeycomb

| Parameter | Details |

|---|---|

| Core Thickness | 6mm, 8mm, 10mm, 20mm (custom available) |

| Cell Size | 3mm, 6mm, 10mm diameter |

| Panel Sizes | 4×8 ft (1220x2440mm) standard |

| Density | 30-100 kg/m³ (adjustable) |

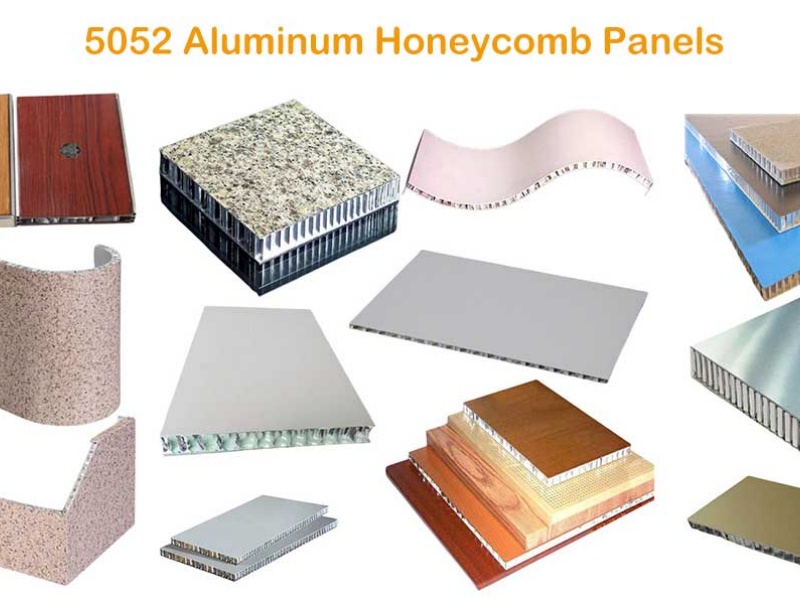

| Face Sheet Options | 1050, 3003, 5052 alloys |

| Surface Finish | Mill, anodized, PVDF coated |

Key Advantages

Ultra-Lightweight – 1/5 the weight of solid aluminum

High Strength – Superior load-bearing capacity

Fire Resistant – Meets A2 fire safety standards

Thermal Insulation – Excellent energy efficiency

Easy to Fabricate – Can be cut, bent, and drilled

Corrosion Resistant – Ideal for harsh environments

Applications

1. Aerospace & Transportation

- Aircraft interior panels

- High-speed train ceilings

- Marine bulkheads

2. Architecture & Construction

- Curtain wall systems

- Elevator interiors

- Decorative wall panels

3. Industrial Uses

- Cleanroom partitions

- Machine guards

- Solar panel backing

4. Signage & Displays

- Exhibition stands

- Digital signage backings

- Museum displays

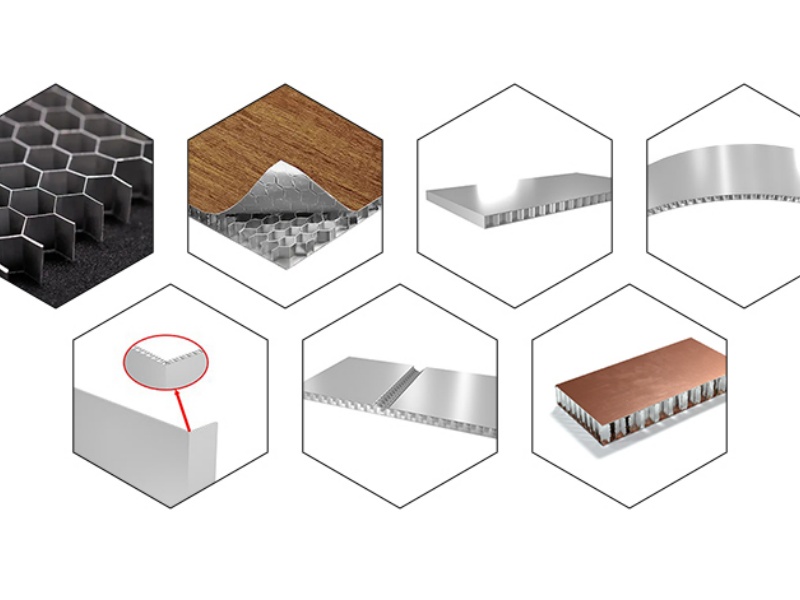

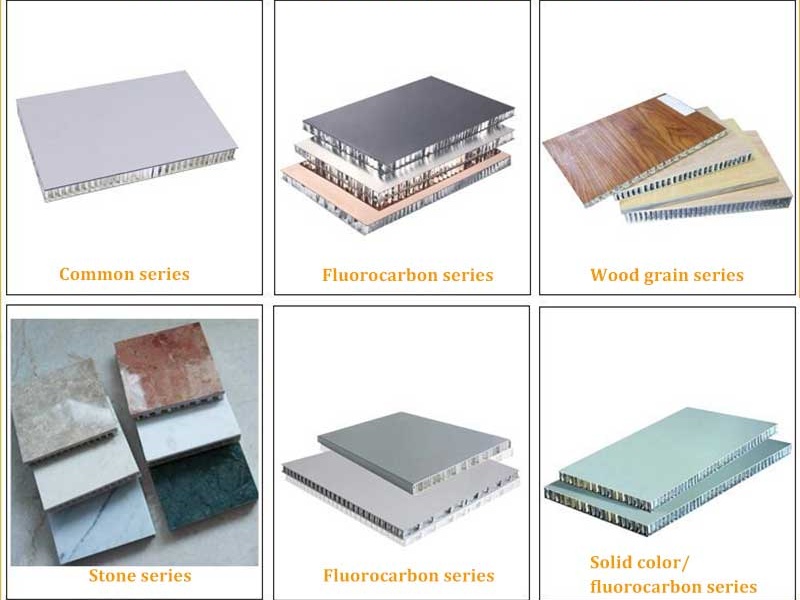

Product Types

1. Extruded Aluminum Honeycomb Core

- Raw core material for custom panel fabrication

- Available in various cell sizes and thicknesses

2. 6mm-20mm Honeycomb Panels

- Pre-fabricated panels for immediate use

- Standard thicknesses: 6mm, 8mm, 10mm, 20mm

3. Alu Honeycomb Wall Panel with Extrusion Profile

- Integrated edge profiles for easy installation

- Hidden clip systems available

Extruded Aluminum Honeycomb Core

The extruded aluminum honeycomb core is the heart of the panel, providing:

- Superior Rigidity: Ideal for load-bearing applications.

- Lightweight Design: Reduces structural weight without compromising strength.

- Customizable Sizes: Available in different cell diameters and thicknesses.

6mm 8mm 10mm 20mm Extruded Aluminum Honeycomb Panel

Aluminum honeycomb panels come in various thicknesses to suit different needs:

- 6mm & 8mm: Ideal for interior applications and decorative uses.

- 10mm: Suitable for lightweight structural components.

- 20mm: Used for high-strength architectural and transportation projects.

Pricing Information

Aluminum honeycomb panels 4×8 price range:

- 6mm thickness: 25−25−40 per m²

- 10mm thickness: 40−40−65 per m²

- 20mm thickness: 80−80−120 per m²

Prices vary based on face sheet material and finish

Why Choose Our Aluminum Honeycomb Panels?

- ISO 9001 Certified Manufacturing

Custom Sizes and Specifications

Fast Lead Times (7-15 days for bulk orders)

Technical Support Available

Aluminum Honeycomb Panel Manufacturer

As a leading manufacturer, we provide:

- High-Quality Materials: Premium aluminum alloys for durability.

- Customization Options: Tailored sizes, finishes, and coatings.

- Fast Production & Delivery: Reliable supply chain for timely shipments.

Alu Honeycomb Wall Panel with Aluminum Extrusion Profile

Honeycomb wall panels with aluminum extrusion profiles offer:

- Enhanced Structural Integrity: Stronger edges and secure connections.

- Modern Aesthetic Appeal: Sleek and professional appearance.

- Easy Installation: Compatible with various mounting systems.

Aluminum Honeycomb Panels 4×8 Price

Pricing depends on:

- Material Grade: 3003 vs. 5052 alloy.

- Panel Thickness: Thicker panels cost more.

- Surface Coating: Anodizing and PVDF coatings impact price.

- Order Quantity: Bulk discounts available.

For the latest pricing, contact us for a detailed quote.

Package Options

- Standard: Wooden crates with foam protection

- Export: Seaworthy pallets with waterproof wrapping

- Custom: Pre-cut kits with protective film

Frequently Asked Questions

Q: What’s the difference between extruded and expanded honeycomb?

A: Extruded cores have more consistent cell structure while expanded cores are more cost-effective.

Q: Can these panels be used outdoors?

A: Yes, with proper PVDF coating or anodized finish.

Q: What’s the maximum panel size available?

A: Up to 1500x4000mm for special orders.

Q: How do you cut honeycomb panels?

A: CNC routing or waterjet cutting recommended for clean edges.

What Are Aluminum Honeycomb Panels?

- Honeycomb core – Hexagonal cell structure for maximum strengt

- Aluminum face sheets – 0.2mm-2.0mm thick protective layers

- Bonding adhesive – High-performance structural adhesive

Extruded aluminum honeycomb panels provide the perfect balance of strength, durability, and lightweight performance for various industries. Contact us today to learn more!