Aluminium Sheet Price

Understanding the aluminium sheet price is crucial for anyone involved in manufacturing, construction, or DIY projects. Aluminium sheets are incredibly versatile, used in everything from building facades and vehicle bodies to signs and intricate consumer products. However, the cost of an aluminium sheet isn’t fixed; it varies significantly based on several factors.

What is an Aluminium Sheet?

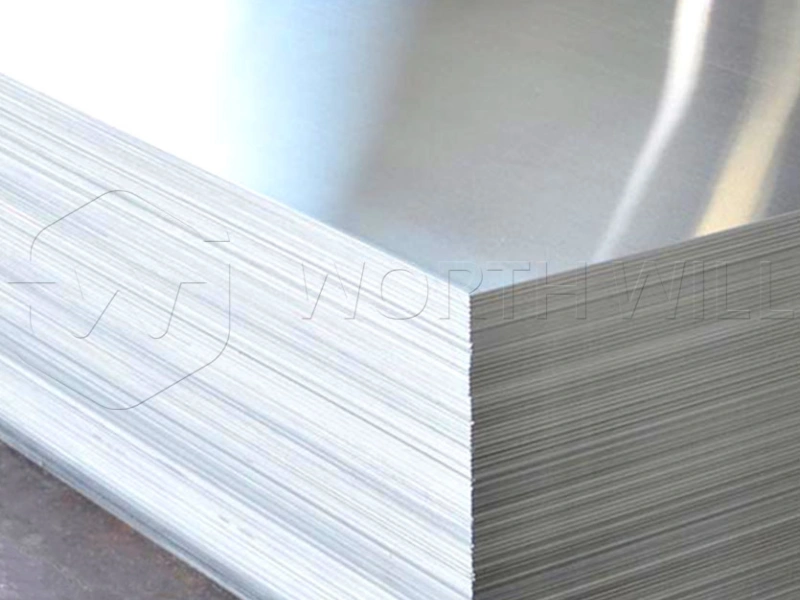

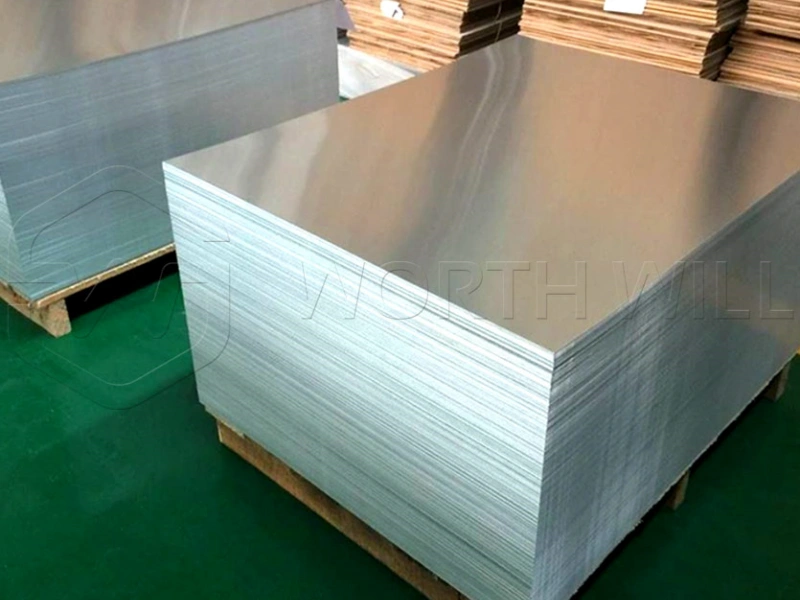

An aluminium sheet is a flat, thin piece of aluminium metal, typically ranging in thickness from very thin foils (though we’re focusing on thicker sheets here) up to about 6mm (0.25 inches). Anything thicker is generally referred to as an aluminium plate. These sheets are produced by rolling large slabs of aluminium until they reach the desired thickness. They come in various standard sizes, with 4×8 sheets of aluminium (4 feet by 8 feet) being one of the most common dimensions.

Key properties that make aluminium sheets so popular include:

- Lightweight: Significantly lighter than steel, which helps reduce overall weight in many applications.

- Corrosion Resistance: Forms a natural oxide layer that protects against rust and corrosion.

- Formability: Can be easily bent, cut, and shaped.

- Good Conductivity: Excellent conductor of electricity and heat.

- Recyclability: Highly recyclable, making it an environmentally friendly material.

These characteristics contribute to the demand, and thus the aluminium sheet price.

Factors Influencing Aluminium Sheet Price

Many elements come into play when determining the price of an aluminium sheet. Understanding these factors will help you get the best value for your project.

1. Alloy Type: The Core of Quality

The specific alloy used is perhaps the most significant factor influencing aluminium sheet price. An alloy is a mixture of aluminium with small amounts of other elements (like copper, magnesium, silicon, manganese, zinc). These additions enhance specific properties, making the aluminium suitable for different applications.

Let’s look at some common alloys for aluminium sheet:

- Aluminium Sheet – 3003 Alloy:

- Properties: Alloyed with manganese. Offers good strength (about 20% stronger than pure aluminium), excellent workability, and good corrosion resistance. It’s non-heat-treatable.

- Uses: General purpose, cookware, storage tanks, building materials, and decorative trim.

- Price Impact: Generally more affordable than some higher-strength alloys due to its commonality and easier processing.

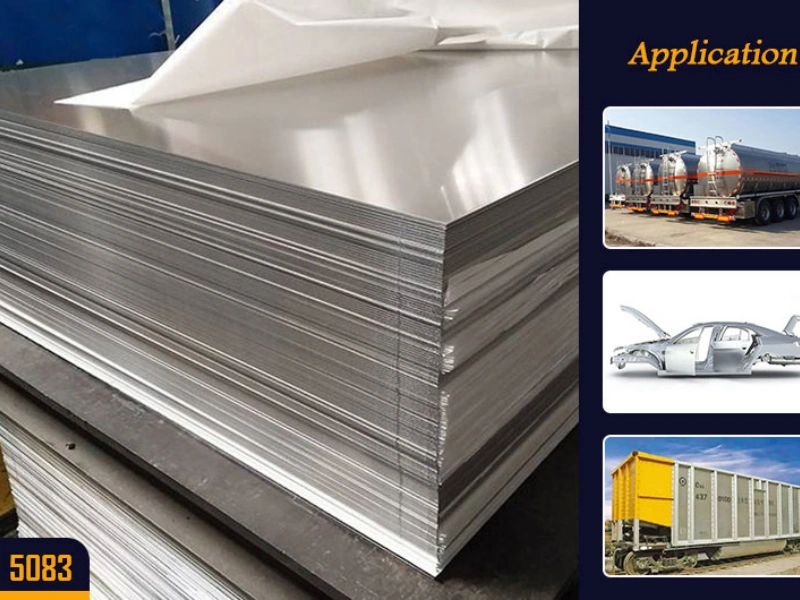

- Aluminium Sheet – 5052 Alloy:

- Properties: Alloyed with magnesium. Known for its high strength, excellent corrosion resistance (especially in marine environments and saltwater), and good weldability. It’s a non-heat-treatable alloy.

- Uses: Marine applications, automotive parts, pressure vessels, fuel tanks, and electronics enclosures. Often referred to as Marine Grade Aluminium Sheets for Sale.

- Price Impact: Typically commands a higher price than 3003 due to its superior strength and corrosion resistance.

- Aluminium Sheet – 6061 Alloy:

- Properties: Alloyed with silicon and magnesium. This is a heat-treatable alloy, meaning its strength can be significantly increased through heat treatment (like T6 temper). Offers medium to high strength, good corrosion resistance, excellent weldability, and good machinability.

- Uses: Structural components, architectural applications (e.g., window frames, railings), bicycle frames, aerospace parts, and general engineering.

- Price Impact: Often among the higher-priced aluminium sheet options due to its high strength and the additional processing required for heat treatment.

The choice of alloy is critical for performance and directly influences the manufacturing complexity, thereby impacting the final aluminium sheet price.

2. Thickness (Gauge): “What is the price of 26 gauge aluminium sheet?”

Thickness plays a direct role in aluminium sheet price. Sheets are often specified by their thickness in millimeters (mm) or by gauge number (a smaller gauge number indicates a thicker sheet).

- Thicker sheets require more raw material and more rolling time, generally leading to a higher per-square-foot or per-kilogram price.

- 26 gauge aluminium sheet is quite thin (around 0.404 mm or 0.0159 inches). Its price per sheet will be lower than a thicker sheet of the same alloy and size, primarily because it uses less material. However, the price per pound or kilogram might be relatively higher due to the increased manufacturing effort involved in rolling it so thin.

3. Dimensions (Size): “How much does a 4×8 sheet of aluminum weigh?”

The dimensions of the sheet (length and width) also affect the aluminium sheet price. Standard sizes like a 4×8 sheet of aluminium are usually more cost-effective per square foot because they are produced in large volumes. Custom or unusually large sizes may incur a premium.

To answer “How much does a 4×8 sheet of aluminum weigh?”:

The weight depends on the alloy and thickness. A common density for aluminium is about 2.7 grams per cubic centimeter (or 0.0975 pounds per cubic inch).

For a 4×8 sheet (48 inches x 96 inches):

Weight (lbs) = Length (in) x Width (in) x Thickness (in) x Density (lbs/cu.in.)

Example for a 0.063-inch thick (approx. 16 gauge) 4×8 sheet of 6061 aluminium:

Weight = 48 in x 96 in x 0.063 in x 0.0975 lbs/cu.in. ≈ 28.3 lbs

This weight directly correlates to the aluminium sheet price.

4. Surface Finish

The surface finish can also affect the price. Common finishes include:

- Mill Finish: The standard finish as it comes off the rolling mill. Often dull or slightly textured. This is the most economical option.

- Brushed or Polished: Achieved through mechanical finishing for a more aesthetic appearance. Adds to the price.

- Anodized: An electrochemical process that thickens the natural oxide layer, enhancing corrosion resistance and allowing for coloring. Significantly increases the aluminium sheet price.

- Coated/Painted: Applied with paint, lacquer, or other protective layers. Adds to the cost.

5. Temper

Temper refers to the hardness or strength of the aluminium sheet, achieved through heat treatment or mechanical working. Common tempers like “O” (annealed/soft), “H” (strain hardened), or “T” (heat-treated) affect the manufacturing process and thus the price. Heat-treated tempers often require more processing and can be more expensive.

6. Quantity Ordered

Like most industrial products, purchasing larger quantities of aluminium sheet often results in a lower per-unit price due to economies of scale in manufacturing and shipping. Suppliers typically offer bulk discounts.

7. Market Conditions & Raw Material Price: “What is the price of 1 kg of aluminium?”

The global market price of raw aluminium is the most significant underlying factor for aluminium sheet price. This price is influenced by global supply and demand, energy costs, and geopolitical factors, often tracked on exchanges like the London Metal Exchange (LME).

“What is the price of 1 kg of aluminium?” This refers to the raw commodity price, not the finished sheet. The aluminium sheet price will always be higher than the raw material price per kg, as it includes manufacturing, processing, transportation, and supplier overheads and profit margins. Raw aluminium prices fluctuate daily.

8. Aluminium Sheet & Plate | Cut to Size | For Sale

Many suppliers offer aluminium sheet & plate cut to size. While this service adds a processing fee, it can actually reduce your overall project cost by:

- Minimizing Waste: You only pay for the exact dimensions you need, eliminating scrap.

- Saving Time & Labor: No need for in-house cutting or specialized equipment.

- Ensuring Precision: Professional cutting services offer high accuracy.

So, while the per-pound or per-square-foot price of a cut to size piece might seem higher, the overall project cost can be lower due to these efficiencies.

How much is an Aluminium Sheet? (General Pricing Outlook)

Given all the factors discussed, it’s impossible to give a single definitive answer to “How much is an aluminium sheet?” The aluminium sheet price can range from a few dollars per square foot for a common thin gauge 3003 sheet to significantly higher for thick, specialized alloys like 6061-T6 or marine-grade 5052, especially if ordered in smaller quantities or with custom finishes.

Key takeaway: Always request a specific quote based on your exact requirements (alloy, thickness, dimensions, quantity, and desired services like cut to size).

Where to Buy Aluminium Sheet & Plate | For Sale

You can find aluminium sheets for sale from various sources:

- Metal Service Centers: These are specialized distributors that stock a wide range of metals, including various aluminium sheet alloys and sizes. They often offer aluminium sheet & plate cut to size services.

- Online Suppliers: Many online platforms allow you to specify dimensions, alloy, and thickness and get instant quotes, sometimes even for cut to size pieces.

- Direct from Mills: For very large, bulk orders, purchasing directly from an aluminium rolling mill might be an option, but this is less common for typical project sizes.

Common Applications of Aluminium Sheets

The widespread use of aluminium sheets across industries reflects their adaptable properties:

- Transportation: Aircraft fuselages, truck trailers, railcars, and automotive body panels (often where lightweighting is critical).

- Building & Construction: Roofing, siding, wall panels, architectural accents, decorative elements, and structural components.

- Packaging: Cans, caps, and flexible packaging (though typically much thinner gauge than “sheet”).

- Consumer Goods: Appliances, cookware, furniture, and electronic casings.

- Industrial Applications: Chemical processing equipment, heat exchangers, and machinery components.

- Signs & Displays: Durable and weather-resistant material for outdoor and indoor signage.

Available Aluminium Alloys for Custom Cutting

- 1050 / 1060 / 1100 – Commercially pure, great for electrical conductivity

- 3003 – Good for general use with better strength than pure grades

- 5052 – Marine-grade alloy with excellent corrosion resistance

- 6061 – Structural alloy, strong and machinable

- 7075 – Aerospace-grade, high strength for demanding tasks

How is Cut-to-Size Aluminium Supplied?

- In sheet, plate, strip, or profile form

- With protective film if needed

- Can include customized edges or holes

- Palletized for bulk shipment or boxed for small orders

FAQs

Q: What is the price of aluminium sheet?

A: Prices vary by thickness, alloy, and market rates. Contact suppliers for current quotes.

Q: How much does a 4×8 sheet of aluminum weigh?

A: It depends on thickness and alloy. For example, a 1/8″ thick 4×8 5052 sheet weighs around 42 kg.

Q: What is the price of 26 gauge aluminium sheet?

A: 26 gauge (~0.4mm) sheets are typically used for roofing and packaging. Prices depend on alloy and quantity.

Q: What is the price of 1 kg of aluminium?

A: Based on current LME and processing costs, the price can range from $2 to $4 per kg.

Q: Can I get just one piece of custom aluminium?

A: Yes, small quantity orders are welcome. Minimum order depends on supplier.

Q: How precise is the cutting tolerance?

A: Cutting tolerances are typically ±0.5mm, but can be improved for laser or CNC cuts.

Q: Are surface finishes available?

A: Yes. Anodizing, powder coating, and brushed finishes can be applied.

Conclusion

The aluminium sheet price is a dynamic figure influenced by factors like alloy type (e.g., 3003, 5052, 6061), thickness (like 26 gauge aluminium sheet), dimensions (e.g., 4×8 sheet of aluminium), surface finish, temper, and order quantity. Understanding these elements is key to navigating the market effectively. Whether you’re seeking Marine Grade Aluminium Sheets for Sale or a standard general-purpose sheet, always define your needs precisely and compare quotes from multiple suppliers, especially considering aluminium sheet & plate cut to size options for efficiency and waste reduction. By doing so, you can ensure you get the right aluminium sheet for your project at the most competitive price.

Leave a Comment

You must be logged in to post a comment.