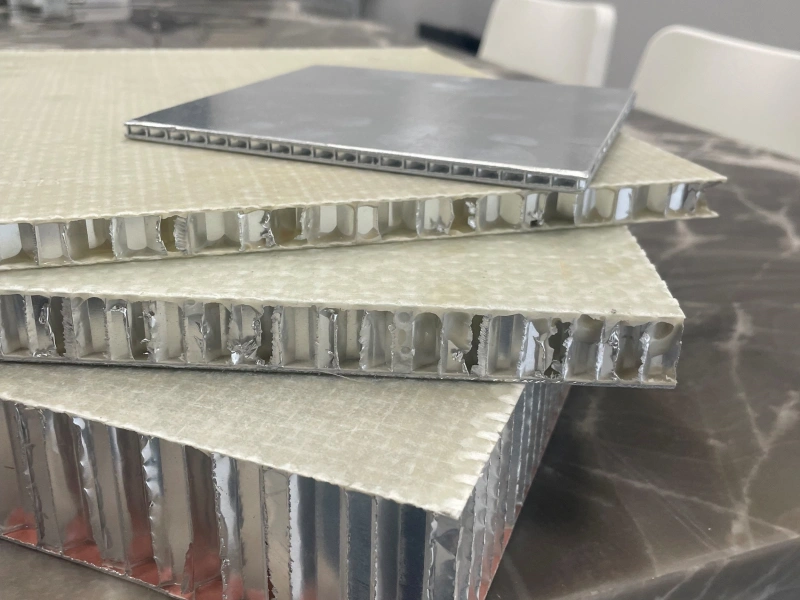

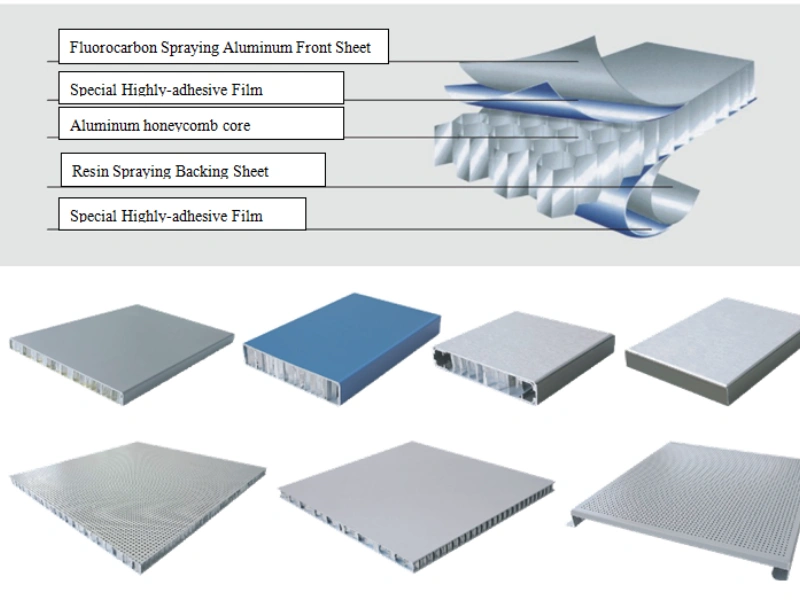

Aluminum honeycomb sandwich panel is an advanced composite material that combines two high-strength aluminum face sheets with an aluminium honeycomb core. Originally developed for aerospace applications, this innovative material now revolutionizes construction and transportation industries with its exceptional strength-to-weight ratio.

Applications

Aluminium honeycomb sandwich panels are versatile and suitable for a variety of applications, including:

- Applications of Aluminium Honeycomb Panels

- The versatility of aluminum honeycomb panels makes them suitable for a wide range of applications, including:

- Interior Decoration: Used for ceilings, wall panels, and partitions in homes and offices.

- Building Facades: Ideal for architectural cladding and curtain walls due to their lightweight and weather-resistant properties.

- Advertising Boards: Perfect for durable and lightweight signage.

- Marine Construction: Used in shipbuilding for panels and partitions.

- Aerospace Industry: Employed in aircraft interiors and components for weight reduction.

- Retail Displays: Used for showroom displays and exhibition stands.

These panels bring aerospace technology into everyday architecture and industrial design.

Specification of Aluminium Honeycomb Panels

| Product Name | Aluminium Honeycomb Sandwich Panel |

|---|---|

| Width | 1220–1500 mm |

| Length | 2440–3200 mm |

| Thickness | 7–25 mm |

| Customization | Designs and sizes according to requirements |

We also offer custom solutions to meet specific project needs.

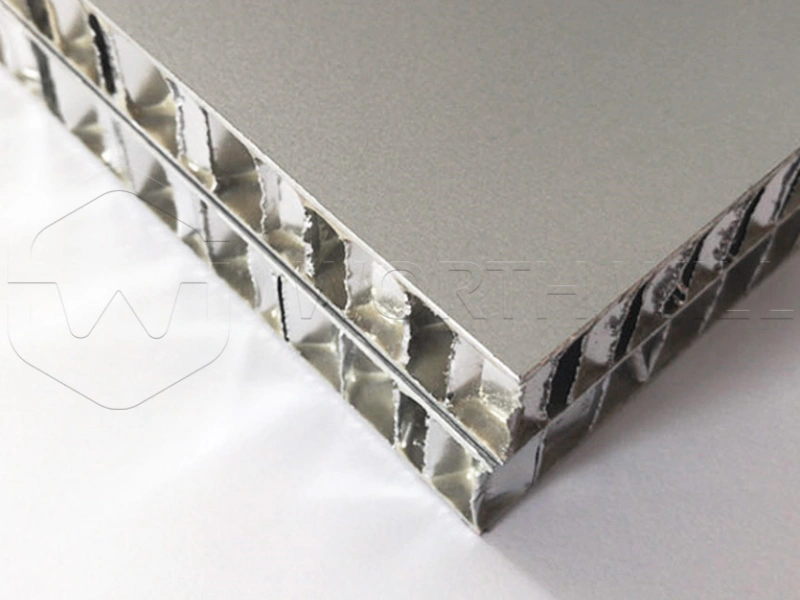

Aluminium Honeycomb Panel Thickness

Choosing the right thickness for your aluminium honeycomb panel depends on the intended use. Common thicknesses range from 7mm to 25mm. Thicker panels provide better strength and rigidity, ideal for structural and heavy-duty applications, while thinner panels are more suited for lightweight designs and decorative purposes.

Factors Affecting Aluminium Honeycomb Panel Price

Several factors influence the price of aluminium honeycomb panels, such as:

- Thickness and size of the panel

- Surface coating and finish type

- Core density and cell size of the honeycomb

- Quantity ordered and customization requirements

- Packaging and transportation fees

We strive to offer the best prices while maintaining premium quality.

Popular Types of Aluminium Honeycomb Panels

There are several popular types of aluminium honeycomb sandwich panels, including:

- PE/PVDF coated aluminium panels

- Stone or marble-faced aluminium panels

- Fireproof aluminium honeycomb panels

- Mirror finish aluminium panels

- Anodized aluminium honeycomb panels

Each type is designed for specific industries and applications, offering flexibility for your projects.

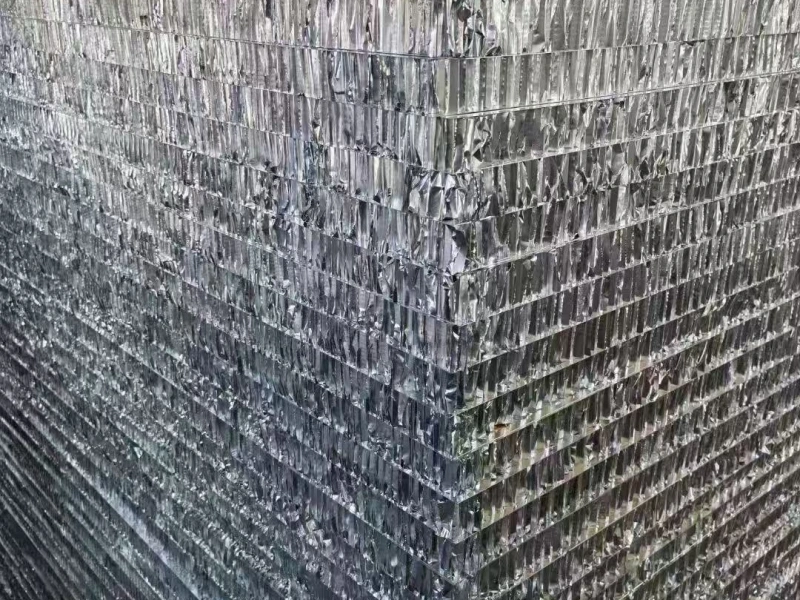

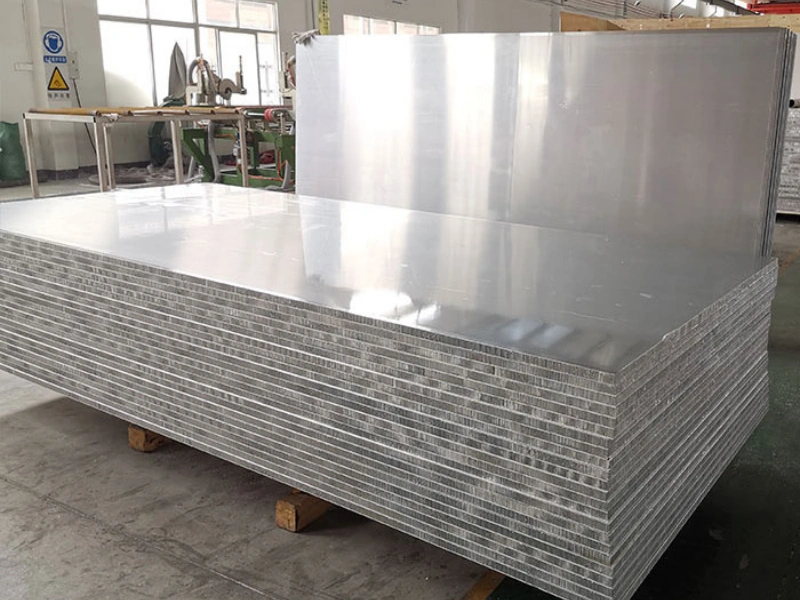

Aluminium Sizes Honeycomb Panel

We provide a wide range of sizes for aluminium honeycomb panels to suit different project needs. Whether you need standard sheets or custom-cut panels, we are ready to assist.

2025 Aluminum Honeycomb Panel

The 2025 aluminum honeycomb panel series is built with advanced materials offering higher strength and enhanced corrosion resistance. It’s ideal for aerospace, shipbuilding, and high-end construction projects.

Lightweight Aluminium Honeycomb Composite Panels

Our lightweight aluminium honeycomb composite panels provide exceptional strength-to-weight ratios. They reduce overall structure weight without sacrificing durability, making them perfect for transport vehicles, aircraft, and lightweight structures.

Aluminium Honeycomb Panels at Best Prices

We are committed to offering aluminium honeycomb panels at the best prices without compromising quality. Bulk orders and long-term cooperation can enjoy additional discounts and benefits.

What is an Aluminium Honeycomb Sandwich Panel?

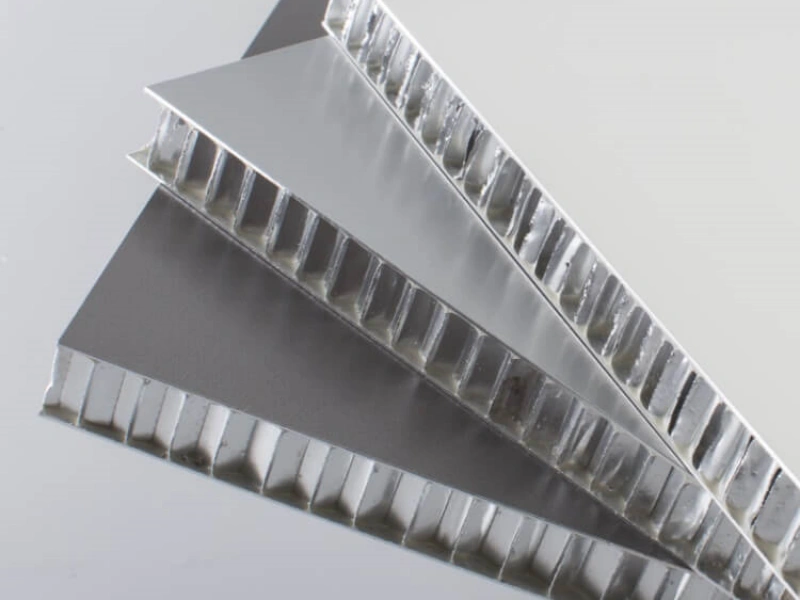

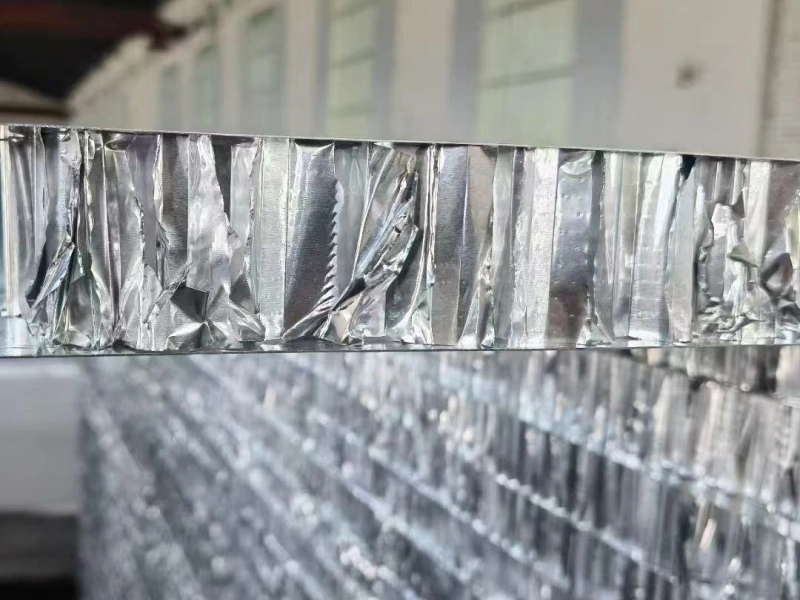

An aluminium honeycomb sandwich panel is a lightweight composite material made with aerospace-grade aluminium alloy sheets as the face and bottom plates. The core is an aluminium honeycomb structure, bonded together using high-strength adhesives under high temperature and pressure. This design offers excellent strength, durability, and weather resistance while keeping the material lightweight.

The face sheets are coated with durable decorative finishes, making the panels ideal for both exterior and interior applications. Aluminium honeycomb panels are widely used in civil construction, marine industries, transportation, and even aerospace manufacturing.

Packaging and Handling

Aluminum honeycomb panels are packed carefully to prevent damage during transit:

- Wooden Crates: For heavy or large panels.

- Plastic Wrapping: To protect the surface finish.

- Corner Guards: To prevent edge damage.

Strength Characteristics of Aluminum Honeycomb Panels

The honeycomb structure provides exceptional strength-to-weight ratios:

- High Stiffness: Resists bending and deformation.

- Impact Resistance: Absorbs shocks effectively.

- Thermal Stability: Maintains shape under temperature variations.

Customized Aluminium Honeycomb Sandwich Panels

Many manufacturers offer customized solutions tailored to specific needs:

- Unique Sizes: Cut to exact dimensions.

- Special Finishes: Powder-coated or anodized surfaces.

- Perforated Panels: For acoustic or aesthetic purposes.

Where to Buy Aluminum Honeycomb Panels at Best Prices

For high-quality aluminum honeycomb panels at competitive prices, consider:

- Reputable Manufacturers: Look for ISO-certified suppliers.

- Online Marketplaces: Compare prices and reviews.

- Local Distributors: For faster delivery and support.

Price Factors

- Panel thickness (thicker = higher cost)

- Face material grade (5052 > 3003)

- Custom finishes (anodized > powder-coated)

- Order quantity (bulk discounts available)

Price Range: 50−50−200/m² depending on specifications

Quality Assurance

- ISO 9001 certified production

- Third-party testing reports

- 10-year performance warranty

- CE, ASTM, EN standards compliant

FAQs

Q: How does it compare to solid aluminum?

A: 80% lighter with 90% strength retention

Q: Can it be curved?

A: Yes, minimum radius = 50x panel thickness

Q: What’s the lead time?

A: 7-15 days for standard sizes

Why Our Panels?

Factory-direct pricing

Custom engineering support

Global shipping experience

Technical documentation provided

Contact us today for your project requirements!