Aluminium Facade Systems

aluminium facade systems is stand out for their aesthetic appeal, durability, and performance. Whether you’re designing a new skyscraper or renovating an existing structure, understanding the benefits and types of Aluminium Facade | Architectural Facade Systems International is crucial.

Aluminium Facade | Architectural Facade Systems International

Aluminium facade systems are modern exterior cladding solutions used for commercial, residential, and industrial buildings. They provide aesthetic appeal, weather protection, and long-term durability. High-quality aluminum facades are lightweight, corrosion-resistant, and easy to maintain.

What is an Aluminium Facade?

An aluminium facade is an architectural exterior covering made of aluminum panels or composite materials. It serves multiple functions:

- Protects the building from weather and environmental damage

- Enhances energy efficiency through thermal insulation

- Improves aesthetic appearance

- Provides a sustainable and long-lasting cladding solution

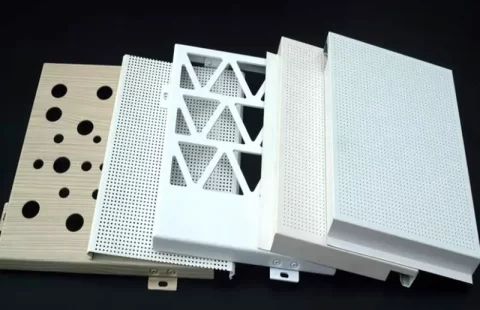

Types of Aluminium Facade Systems

Aluminium facades come in different types to suit design and functional requirements:

- Aluminium Composite Panels (ACP): Lightweight, smooth surface, ideal for modern architecture

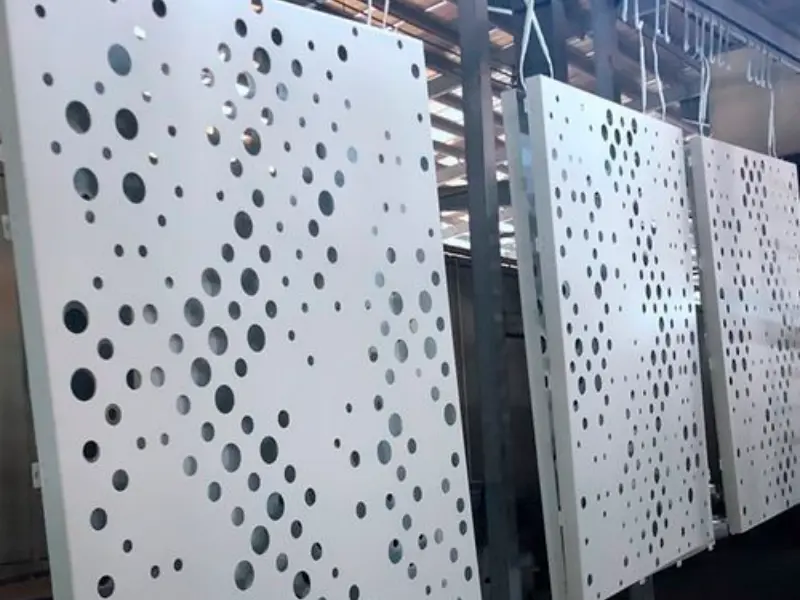

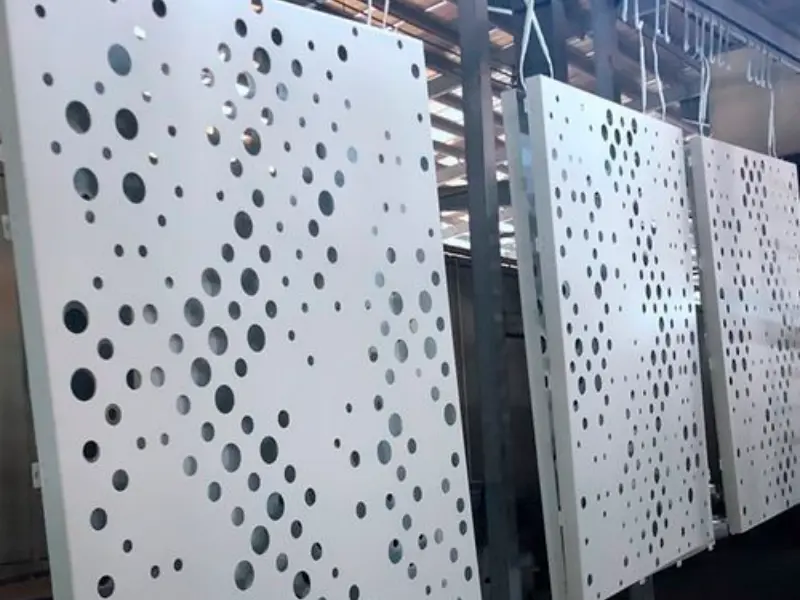

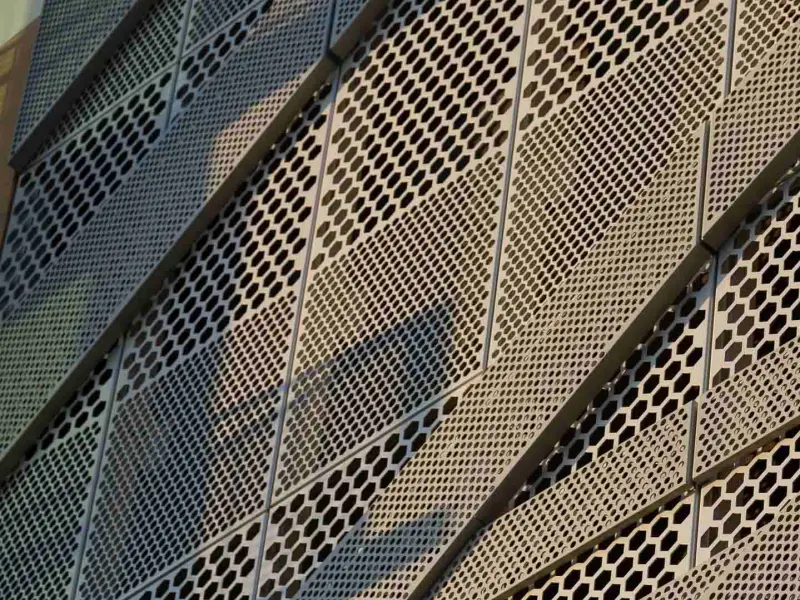

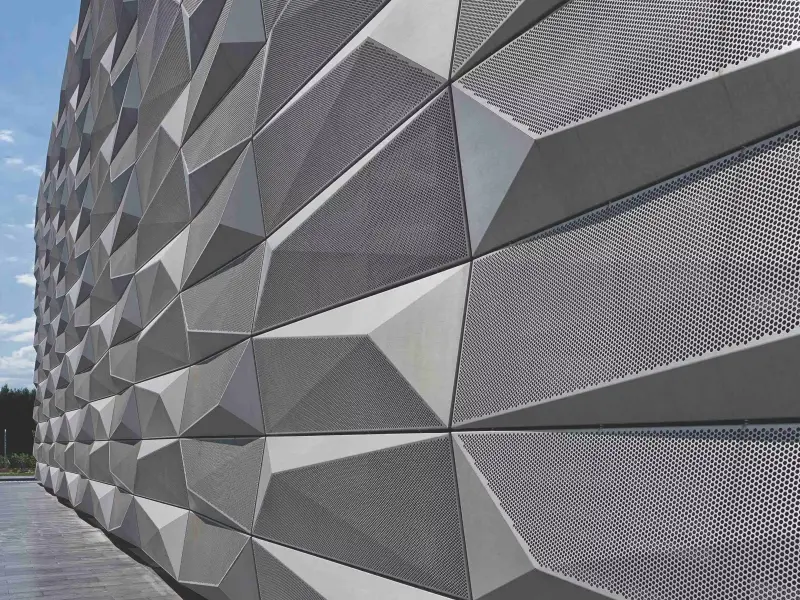

- Perforated Aluminium Panels: Allows natural ventilation and unique visual effects

- Aluminium Cladding Panels: Durable, for protective and decorative purposes

- Anodized Aluminium Panels: Offers superior corrosion resistance and long-lasting color

Common Aluminium Facade Types

| Type | Thickness (mm) | Finish | Typical Use |

|---|---|---|---|

| ACP Panels | 3 – 6 | PVDF, PE | Commercial & Residential Buildings |

| Perforated Panels | 2 – 5 | Powder Coated | Ventilation & Decorative Façade |

| Aluminium Cladding | 2 – 8 | Brushed, Painted | Exterior Protection & Aesthetics |

| Anodized Panels | 1.5 – 5 | Anodized Silver / Bronze | Long-term durable façades |

What is the Lifespan of Aluminium Facade?

High-quality aluminium facade systems are durable and can last for decades:

- Standard ACP and cladding panels: 20 – 30 years

- Anodized aluminum panels: 30 – 50 years

- Proper installation and maintenance significantly extend the lifespan

How Much Does an Aluminium Facade Usually Cost?

The cost depends on several factors:

- Type of panel (ACP, perforated, anodized)

- Thickness and size of panels

- Finish and coatings (PVDF, powder coat, anodized)

- Installation complexity and labor cost

Indicative Prices for Aluminium Facade Panels

| Panel Type | Thickness (mm) | Price Range (USD/m²) | Notes |

|---|---|---|---|

| ACP Panels | 3 – 6 | 25 – 50 | Standard commercial use |

| Perforated Panels | 2 – 5 | 35 – 60 | Decorative & ventilated façades |

| Cladding Panels | 2 – 8 | 30 – 55 | Durable exterior protection |

| Anodized Panels | 1.5 – 5 | 40 – 70 | High corrosion resistance |

Finishes for Aluminium Facade

Aluminium facades can have multiple finishes to meet aesthetic and functional needs:

- PVDF Coating: Bright, long-lasting color

- Powder Coating: Wide range of colors, smooth finish

- Anodized: Metallic, scratch-resistant

- Brushed / Textured: Modern architectural look

Factory & Production

Our aluminium facade systems are produced in advanced facilities that ensure:

- High-quality raw materials

- Precision cutting and finishing

- Custom sizes, thicknesses, and finishes

- Strict quality control and compliance with international standards

Why Choose Aluminium Facade Systems? The Benefits

The widespread adoption of aluminium facade systems in modern construction is due to their impressive array of advantages:

- Exceptional Durability: Aluminium is naturally resistant to corrosion, rust, and degradation from UV light, ensuring a long service life.

- Lightweight Material: Being significantly lighter than steel or concrete, aluminium reduces the structural load on the building, potentially lowering construction costs and allowing for more expansive designs.

- Design Flexibility: Aluminium can be easily extruded, cut, formed, and finished in a myriad of shapes, colors, and textures, offering architects unparalleled creative freedom in facade design.

- Energy Efficiency: Many aluminium facade designs incorporate advanced glazing and insulation techniques to improve thermal performance, reducing heating and cooling costs for the building.

- Low Maintenance: Aluminium surfaces are generally easy to clean and require minimal upkeep, saving time and money over the building’s lifespan.

- Sustainability: Aluminium is 100% recyclable without loss of quality, making it an environmentally friendly choice for sustainable building practices.

Applications

Aluminium facades are used in a wide range of buildings:

- Commercial buildings and offices

- Residential apartments and villas

- Airports, train stations, and public buildings

- Shopping malls and retail outlets

- Industrial facilities and warehouses

FAQ – Frequently Asked Questions

Q1: What is an aluminium facade?

It is an exterior building covering made of aluminum panels or composite materials.

Q2: What is the lifespan of an aluminium facade?

Depending on quality and maintenance, 20 to 50 years.

Q3: What finishes are available for aluminium facades?

PVDF, powder coating, anodized, brushed, and textured finishes.

Q4: Can aluminium facades be customized?

Yes, panels can be cut to size, and colors or textures can be tailored to design needs.

How much does a facade usually cost?

How much does a facade usually cost? This is one of the most common questions, but also one of the most variable. The cost of an aluminium facade system can range significantly, typically from $50 to $300 per square foot (or €500 to €3000 per square meter) or more, depending on numerous factors. It’s crucial to obtain detailed quotes based on your specific project.

Factors influencing the cost include:

Installation Costs: Labor, equipment, and scaffolding can be significant portions of the total cost.

Type of System: Curtain walling and unitized systems are generally more expensive than ACP or simple rain screen systems.

Material Quality & Specification: Premium alloys, thicker panels, and specialized components increase costs.

Finish: PVDF coatings and complex anodizing processes are more costly than standard powder coating.

Design Complexity: Custom shapes, intricate patterns, and advanced engineering raise the price.

Building Height & Location: Taller buildings require more robust systems and specialized installation equipment. Site accessibility and local labor costs also play a role.

Thermal Performance Requirements: Higher insulation values or advanced glazing for energy efficiency can add to the cost.

Project Size: Larger projects often benefit from economies of scale.

Leave a Comment

You must be logged in to post a comment.