Aluminium Cut to Size

In the world of manufacturing, construction, and custom projects, getting materials exactly right is essential. This is where aluminium cut to size services become invaluable. Instead of buying standard stock lengths or sheets and then cutting them yourself, you can receive aluminium materials precisely trimmed to your required dimensions.

What Does “Aluminium Cut to Size” Mean?

Aluminium cut to size refers to the process where a supplier takes raw aluminium material – be it a large sheet, plate, bar, tube, or extrusion – and cuts it down to the exact length, width, or shape specified by the customer. This bespoke service eliminates the need for in-house cutting, reducing labor costs, material waste, and the potential for errors.

The key benefits of opting for aluminium cut to size include:

- Precision: Materials arrive with exact dimensions, ready for immediate use.

- Reduced Waste: You only pay for the material you need, minimizing scrap.

- Time Savings: No need for your team to spend time on cutting or finishing.

- Cost Efficiency: Saves on labor, equipment, and waste disposal.

- Safety: Professional cutting services reduce workplace hazards associated with material processing.

This customized approach ensures that every piece of aluminium cut to size fits your project’s specifications perfectly.

Classification of Aluminium Materials for Cut to Size

Aluminium is available in various forms, and almost all of them can be supplied as aluminium cut to size pieces. Understanding these classifications helps in specifying the right material for your project.

- Aluminium Sheets:

- Description: Thin, flat pieces of aluminium, typically less than 6mm (0.25 inches) thick.

- Uses: Ideal for lightweight panels, cladding, signs, decorative elements, and general fabrication. When you need aluminium cut to size for these applications, sheets are a common choice.

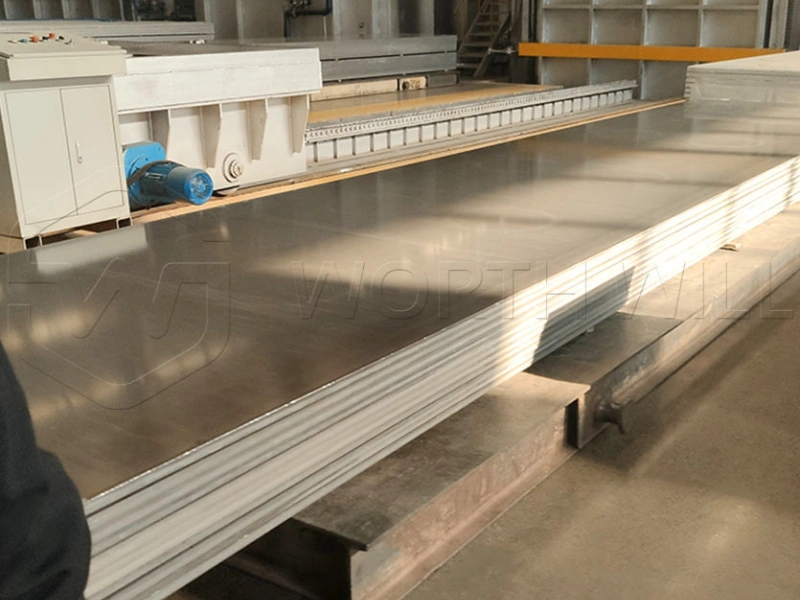

- Aluminium Plates:

- Description: Thicker, flat pieces of aluminium, usually 6mm (0.25 inches) or more in thickness.

- Uses: Used for heavy-duty structural components, base plates, machinery parts, and tooling where greater strength and rigidity are required. Aluminium plate cut to size ensures strong, precise foundations.

- Aluminium Bars:

- Description: Solid, elongated pieces of aluminium available in various cross-sectional shapes (e.g., rectangular, square, round).

- Uses: Commonly used for structural supports, brackets, machine parts, and architectural trim. Getting aluminium bar cut to size is highly efficient for specific lengths.

- Aluminium Tubes & Pipes:

- Description: Hollow sections, either round, square, or rectangular. Tubes are typically used for structural applications, while pipes are for fluid transfer.

- Uses: Frameworks, railings, fluid lines, and light structural components. Aluminium tube cut to size provides ready-to-assemble components.

- Aluminium Extrusions:

- Description: Aluminium formed into specific, often complex, cross-sectional profiles through an extrusion process.

- Uses: Custom architectural elements, window frames, heat sinks, and specialized machine components. Aluminium extrusion cut to size is perfect for projects requiring unique profiles.

Each of these forms can be precisely cut to size, offering tailored solutions for diverse industrial and artistic endeavors.

Alloy: The Foundation of Aluminium Cut to Size Quality

The performance and suitability of any aluminium cut to size product are fundamentally determined by its alloy. An alloy is a metallic substance made by mixing two or more elements, at least one of which is a metal. For aluminium, these other elements (like copper, magnesium, silicon, manganese, zinc) are added in small amounts to enhance specific properties of the pure aluminium.

Different aluminium alloys offer a range of characteristics, affecting properties such as:

- Strength: How much force the material can withstand before deforming or breaking.

- Corrosion Resistance: Ability to resist degradation from environmental factors.

- Weldability: How easily it can be joined by welding.

- Machinability: How easily it can be cut, drilled, or shaped by machine tools.

- Formability: How easily it can be bent or formed without cracking.

Typical uses

- 1xxx Series (e.g., 1050, 1100):

- Properties: High purity, excellent electrical and thermal conductivity, very good corrosion resistance, and high formability. Relatively low strength.

- Uses: Electrical conductors, chemical processing equipment, heat exchangers.

- 3xxx Series (e.g., 3003, 3004):

- Properties: Alloyed with manganese, offering good strength (stronger than 1xxx series) and excellent workability. Good corrosion resistance. Non-heat-treatable.

- Uses: General purpose, cookware, storage tanks, building materials, and roofing.

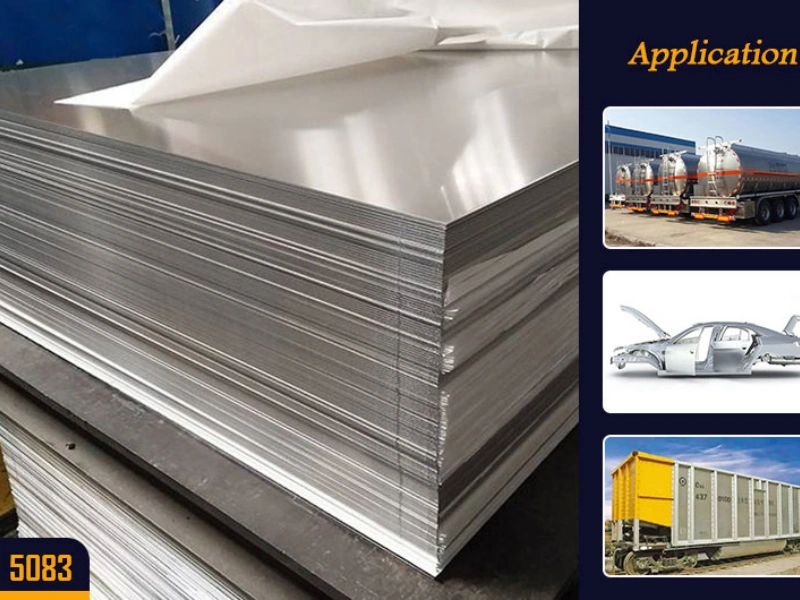

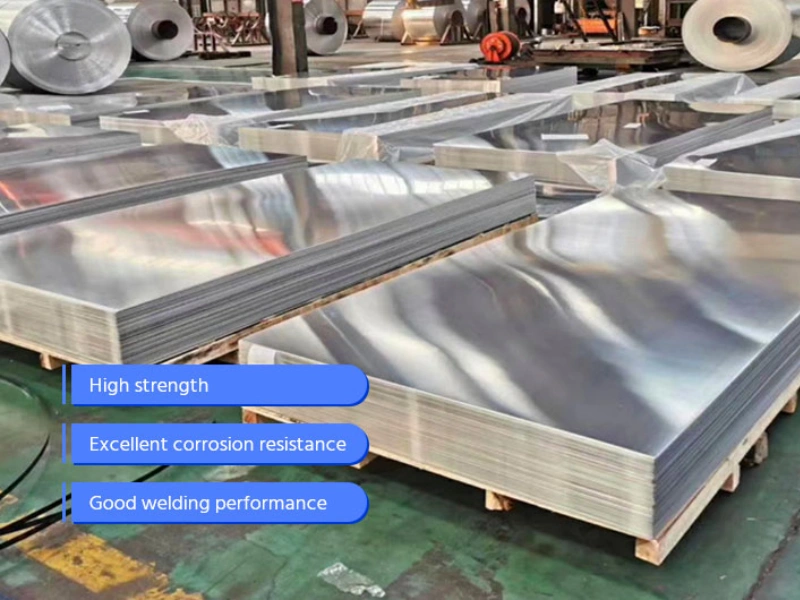

- 5xxx Series (e.g., 5052, 5083):

- Properties: Alloyed with magnesium, known for high strength, excellent corrosion resistance (especially in marine environments), and good weldability.

- Uses: Marine applications, automotive parts, pressure vessels, structural components. Often a premium choice for aluminium cut to size in harsh environments.

- 6xxx Series (e.g., 6061, 6063):

- Properties: Alloyed with silicon and magnesium, these are heat-treatable alloys offering medium to high strength, good corrosion resistance, excellent weldability, and good machinability.

- Uses: Structural components, architectural applications (e.g., window frames, railings), bicycle frames, and general engineering. Very popular for aluminium cut to size structural projects.

- 7xxx Series (e.g., 7075):

- Properties: Alloyed with zinc, offering extremely high strength, comparable to some steels.

- Uses: Aerospace components, high-performance sporting goods, and other demanding applications where maximum strength-to-weight ratio is critical.

Selecting the correct alloy is paramount to ensuring that your aluminium cut to size material performs as expected in its intended application. A reputable supplier will guide you in choosing the best alloy for your specific needs.

Common Cutting Methods for Aluminium

Achieving precise aluminium cut to size dimensions involves various cutting techniques, each suited for different material forms, thicknesses, and required precision levels.

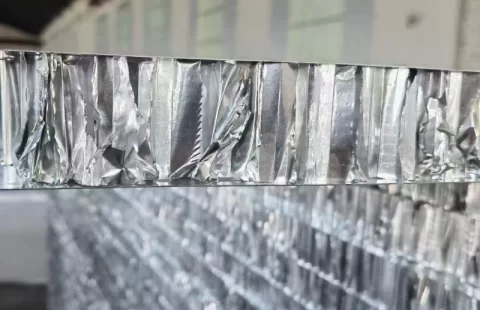

Saw Cutting:

- Method: Uses large circular saws or band saws with specialized blades designed for aluminium.

- Application: Common for cutting bars, tubes, extrusions, and thicker plates to length. It’s fast and cost-effective for straight cuts.

- Shearing (Guillotine Cutting):

- Method: A straight blade descends past a fixed blade, much like giant scissors, to cut sheets and thinner plates.

- Application: Ideal for quick, straight cuts on flat materials up to a certain thickness. It’s efficient for producing rectangular or square aluminium cut to size blanks.

- Laser Cutting:

- Method: A focused high-power laser beam melts, burns, or vaporizes the material.

- Application: Offers high precision, intricate designs, and minimal material distortion. Excellent for complex shapes and fine details on sheets and thinner plates.

- Waterjet Cutting:

- Method: Uses a high-pressure stream of water, often mixed with an abrasive grit, to cut through the material.

- Application: Capable of cutting very thick aluminium, complex shapes, and materials that are sensitive to heat (as it’s a cold cutting process). Offers superior edge quality.

- CNC Machining (Routing/Milling):

- Method: Computer Numerical Control machines use rotating cutting tools to precisely remove material.

- Application: For highly complex 2D or 3D shapes, precise holes, slots, and detailed features, often after an initial rough cut.

The choice of cutting method directly impacts the precision, edge quality, and ultimately the cost of your aluminium cut to size order.

Applications

The demand for aluminium cut to size is vast, driven by its versatility and the specific needs of various industries.

- Construction & Architecture:

- Building facades, roofing components, structural frameworks, custom railings, decorative panels, sun louvers, and window/door frames.

- Automotive & Transportation:

- Chassis components, body panels, brackets, interior trim, truck bodies, and trailer parts, where lightweighting is crucial.

- Aerospace:

- Aircraft fuselage sections, wing components, internal structures, seating frames, and other weight-critical parts.

- Manufacturing & Engineering:

- Machine parts, jigs, fixtures, enclosures for equipment, specialized tooling, and robotic components.

- Electronics:

- Heat sinks for electronic devices, electrical busbars, component housings, and mounting brackets.

- Marine:

- Boat hulls, decks, masts, and other components requiring excellent corrosion resistance in saltwater environments.

- Signage & Displays:

- Backing panels for signs, custom mounting brackets, display stands, and exhibition booths.

- DIY & Hobby Projects:

- Custom frames, shelving, small structural parts for robotics, model making, and art installations.

These diverse applications highlight why aluminium cut to size is such an essential service across countless sectors.

Ordering Your Aluminium Cut to Size

Ordering aluminium cut to size is a straightforward process designed to meet your exact specifications. To ensure you get precisely:

- Dimensions: Exact length, width, and thickness required (e.g., 200mm x 150mm x 5mm). For bars and tubes, specify length and cross-sectional dimensions.

- Material Form: Specify whether you need sheet, plate, bar (round, square, rectangular), tube, or a custom extrusion.

- Alloy and Temper: State the specific aluminium alloy (e.g., 6061-T6, 5052-H32) that best suits your application’s strength, corrosion resistance, and workability requirements.

- Quantity: The number of pieces you need.

- Tolerance: Any specific precision requirements beyond standard cutting tolerances.

- Surface Finish: If a particular finish (e.g., mill finish, brushed, anodized) is required.

- Delivery Requirements: Your preferred timeline and delivery address.

A reputable supplier will guide you through these choices to ensure your aluminium cut to size order meets your project’s demands.

Conclusion

Aluminium cut to size services offer a modern, efficient, and precise way to acquire aluminium materials. By eliminating the need for in-house cutting, this service reduces waste, saves time, and ensures that every piece fits your project perfectly from the start. With a wide range of available forms and alloys, and advanced cutting methods, aluminium cut to size provides tailored solutions for industries from aerospace to architecture and individual custom builders. Investing in precisely cut to size aluminium means investing in the efficiency, quality, and success of your project.

Leave a Comment

You must be logged in to post a comment.