Aluminium Checkered Plate Prices

Aluminium checkered plate, also known as aluminium chequer plate, aluminium tread plate, or aluminum diamond plate. Its distinctive raised pattern not only provides excellent anti-slip properties but also adds a robust aesthetic.

Aluminium checkered plates, also known as tread plates or diamond plates, are lightweight, anti-slip aluminum sheets used in industrial and decorative applications. They come in a variety of patterns and sizes.

- Alloys: 1100, 3003, 5052, 6061

- Thickness: 1.5mm – 8mm

- Width: 1000mm – 1500mm

- Length: Customizable, standard 2440mm or 3000mm

- Patterns: Five bar, diamond, lentil, single bar

- Surface: Mill finish, bright finish, anodized

- Temper: H14, H22, H32, T6

Classification

Aluminum checkered plates can be classified based on:

- Pattern Type:

- Five-bar checkered plate

- Diamond plate

- Lentil/bean pattern

- Alloy Grades:

- 1100/1050: General purpose

- 3003: Good formability, anti-rust

- 5052: Marine-grade, strong corrosion resistance

- 6061: High strength, heat-treatable

Alloy

Common Aluminum Alloys Used in Checkered Plates:

- 1100 Alloy: Soft, low strength, used for decorative use

- 3003 Alloy: Rust-resistant, good for truck flooring and walls

- 5052 Alloy: Ideal for marine and industrial usage

- 6061 Alloy: High-strength for heavy-duty platforms and structures

What Is the Price of Aluminium Chequered Plate?

The price of aluminium checkered plate depends on:

- Alloy type

- Thickness and dimensions

- Surface treatment

- Quantity ordered

- Market aluminum ingot price

💰 Example Prices (subject to market changes):

- 2mm 3003 H22 five-bar plate: USD $2.50 – $3.20/kg

- 3mm 5052 five-bar plate: USD $3.40 – $4.10/kg

- 4.5mm 6061 diamond plate: USD $4.80 – $5.60/kg

📌 Note: Prices fluctuate with aluminum raw material costs. Contact your aluminium checkered plate supplier for current offers and bulk discounts.

What Grade Is Aluminium Chequer Plate?

Different grades offer different strengths and corrosion resistance:

- 1100 & 1050 – Commercially pure aluminum, low strength

- 3003 – Medium strength, good corrosion resistance

- 5052 – High corrosion resistance, marine environments

- 6061 – High strength, heat-treated, structural applications

Each grade is suitable for different environments and loads.

Specification: Key Factors Affecting Aluminium Checkered Plate Prices

Several specifications play a crucial role in determining the overall aluminium checkered plate prices. Understanding these will help you tailor your purchase to your specific needs and budget.

Thickness

The thickness of the plate is a primary factor. Aluminium checkered plate typically ranges from 1.5mm to 6mm, though thicker options are available. Thicker plates offer greater strength and durability but also come with a higher price tag and increased weight.

Pattern Type

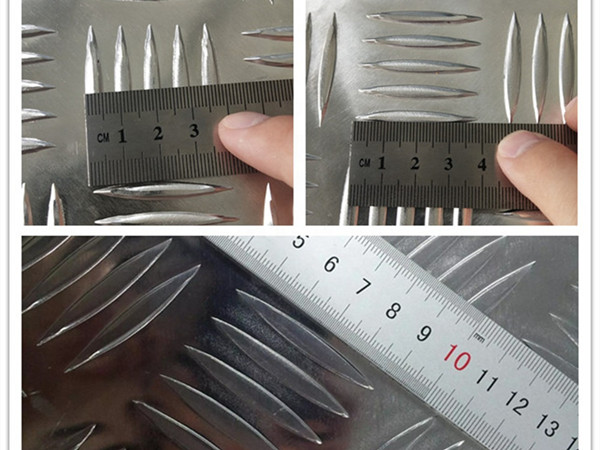

While often generically called “diamond plate,” there are various patterns, including:

- Diamond Plate: The most common, featuring a repeating pattern of raised diamonds.

- Five Bar (or Five Bar Tread Plate): Characterized by groups of five parallel raised lines.

- Three Bar: Similar to five bar but with groups of three lines.

- Propeller Pattern: A less common, more intricate pattern.

The pattern type can slightly influence manufacturing costs and, consequently, the price.

Size (Width and Length)

Aluminium checkered plates come in standard sheet sizes (e.g., 1220mm x 2440mm, 1500mm x 3000mm) or can be custom-cut to specific dimensions. Larger or custom sizes may affect the price per unit area due to reduced yield from standard coils or additional cutting processes.

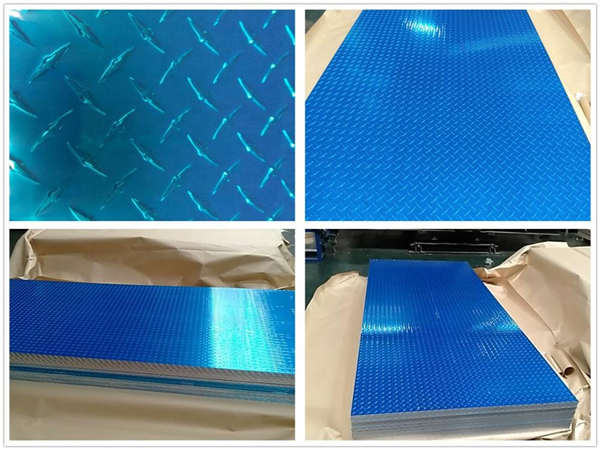

Surface Finish

- Mill Finish: This is the raw, unpolished aluminum surface, which is the most economical. It might show some marks from the manufacturing process.

- Bright Finish: Achieved through polishing, this finish offers a reflective, shiny appearance, often used for decorative purposes, which can increase the cost.

- Anodized Finish: An electrolytic process that creates a thicker, harder, and more corrosion-resistant oxide layer. This adds to the cost but significantly enhances durability and aesthetics.

- Painted/Coated: For specific color or protection requirements, coatings like powder coating can be applied, impacting the final aluminium chequer plate prices.

Classification & Alloy: Understanding Different Grades

The aluminium alloy used in the production of the aluminium checkered plate is a critical factor influencing its properties and cost.

What grade is aluminium chequer plate?

Aluminium chequer plate is commonly available in several grades, each offering a distinct balance of properties:

- 1050 Aluminium Alloy: This is a commercially pure aluminum alloy, known for its excellent ductility, formability, and corrosion resistance. It’s often chosen for general fabrication, insulation, and decorative applications where high strength is not the primary requirement. It’s typically one of the more affordable options.

- 3003 Aluminium Alloy: This is one of the most widely used alloys for aluminium tread plate. It contains manganese, which significantly improves its strength compared to 1000 series alloys, while retaining good formability and excellent corrosion resistance. 3003 aluminium checkered plate is versatile and suitable for a wide range of applications, including general purpose flooring and truck beds.

- 5052 Aluminium Alloy: This alloy contains magnesium and is highly regarded for its superior strength-to-weight ratio and outstanding corrosion resistance, especially in marine environments. 5052 aluminium diamond plate is ideal for applications requiring higher strength and better resistance to saltwater or industrial chemicals, making it a more premium choice.

- 6061 Aluminium Alloy: A heat-treatable alloy containing magnesium and silicon, 6061 offers excellent strength, good corrosion resistance, and good weldability. While not as common for general checker plate as 3003 or 5052, it’s used when structural integrity and high strength are paramount, often in more demanding engineering applications.

The specific aluminium alloy chosen directly impacts the performance, longevity, and ultimately, the aluminium checkered plate prices. Stronger and more corrosion-resistant alloys like 5052 typically come at a higher price point.

Aluminium Chequered Plate Prices: What to Expect?

What is the price of aluminium chequered plate?

The price of aluminium chequered plate varies significantly based on current market conditions, raw material costs (aluminum ingots), the specific aluminium alloy used, thickness, size, finish, and the supplier. As a general guideline, prices are typically quoted per kilogram or per square meter. Due to constant fluctuations in global metal markets, it’s difficult to provide exact figures that remain current. However, expect prices to reflect the balance between aluminum’s value as a commodity and the manufacturing costs involved in producing the textured plate.

How much does an aluminum diamond plate cost?

Since aluminum diamond plate is a specific type of aluminium checkered plate, its cost is determined by the same factors mentioned above: aluminium alloy grade, thickness, size, and finish. For instance, a 3003 aluminum diamond plate will generally be more affordable than a 5052 aluminum diamond plate of the same dimensions and thickness, due to the difference in alloy composition and properties. Always request a current quote from your aluminium checkered plate suppliers for the most accurate pricing.

How much does a 3mm aluminium checker plate weight?

Knowing the weight of your aluminium checker plate is important for transportation, installation, and structural considerations. The density of aluminum is approximately 2.7 grams per cubic centimeter (g/cm³) or 2700 kilograms per cubic meter (kg/m³).

For a 3mm (0.003 meter) thick aluminium checker plate, the approximate weight per square meter is:

Weight = Thickness × Area × Density

Weight per square meter = 0.003 m × 1 m² × 2700 kg/m³ = 8.1 kg/m² (approximately)

Please note that this is an approximate weight for a flat sheet. The raised pattern of a checker plate adds a very slight amount of additional material, so the actual weight might be marginally higher, but 8.1 kg/m² is a good working estimate for a 3mm plate.

What is Aluminium Checkered Plate?

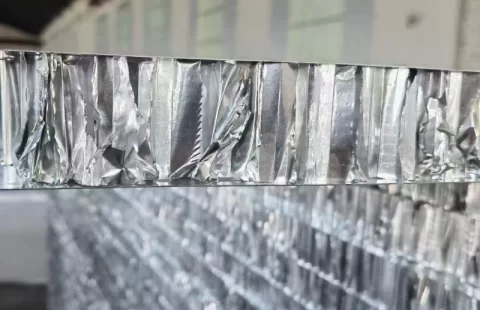

An aluminium checkered plate is a flat sheet of aluminum with a regular pattern of raised lines or diamonds on one side. This texture is created during the rolling process. The primary purpose of these raised patterns is to provide enhanced grip and prevent slipping, making them ideal for areas where safety is paramount. Beyond functionality, the patterned surface also helps to hide scratches and minor imperfections, contributing to its long-lasting appearance. Being made of aluminum, it inherits all the advantages of this metal: it’s lightweight, corrosion resistant, and easy to maintain.

Applications of Aluminium Checkered Plate

The unique combination of properties makes aluminium checkered plate invaluable across a wide range of industries:

- Building & Construction:

- Flooring for industrial facilities, warehouses, and factories.

- Stair treads, ramps, and walkways for safety.

- Decorative wall panels and kick plates.

- Building facades and architectural accents.

- Walk-in freezer floors and cold room linings.

- Transportation:

- Truck bed liners and toolboxes.

- Trailer flooring and ramps.

- Ambulance and emergency vehicle interiors.

- Bus, train, and marine vessel flooring and steps.

- Vehicle running boards and protective guards.

- Industrial:

- Machine platforms and mezzanines.

- Safety platforms and catwalks.

- Equipment enclosures and protective covers.

- Food processing equipment components.

- Work benches and protective surfaces.

- Decorative & Consumer Goods:

- Toolboxes and storage cases.

- Retail displays and exhibition stands.

- Furniture accents and interior design elements.

- DIY projects and custom fabrication.

Factors Influencing Aluminium Checkered Plate Prices

Beyond the specifications, several broader market and supply chain factors impact aluminium checkered plate prices:

- Global Aluminum Market Fluctuations: The price of raw aluminum ingots, which is traded on international commodity markets, directly affects the cost of finished products.

- Energy Costs: Aluminum production is energy-intensive, so fluctuations in electricity and fuel prices can influence manufacturing costs.

- Supplier’s Location and Production Capacity: Local suppliers might offer competitive pricing due to reduced shipping costs, while larger manufacturers might benefit from economies of scale.

- Order Quantity: Larger bulk orders often qualify for significant discounts compared to smaller, one-off purchases.

- Customization and Fabrication: Any special cutting, bending, or finishing requirements beyond standard processes will add to the cost.

- Shipping and Logistics: Freight costs, especially for international orders, can be a substantial part of the final price.

Tips for Buying Aluminium Checkered Plate

When looking for the best aluminium checkered plate prices, consider these tips:

- Define Your Needs: Clearly specify the required aluminium alloy grade, thickness, pattern, size, and finish for your application. This prevents over-specifying and paying for properties you don’t need.

- Get Multiple Quotes: Contact several reputable aluminium checkered plate suppliers to compare prices and lead times.

- Inquire About Discounts: Especially for larger orders, ask about volume discounts.

- Consider Total Cost: Factor in shipping costs, potential cutting charges, and lead times, not just the per-unit price.

- Check for Quality Certifications: Ensure the supplier provides quality materials that meet relevant industry standards.

Conclusion

Aluminium checkered plate is a highly valuable material, offering a unique combination of safety, durability, and aesthetic appeal. Understanding the various factors that influence aluminium checkered plate prices—from the specific aluminium alloy and thickness to market conditions and supplier capabilities—empowers you to make smart purchasing decisions. Whether you need the robust safety of a 3003 aluminium diamond plate for industrial flooring or the superior corrosion resistance of a 5052 alloy for marine use, proper research and communication with aluminium checkered plate suppliers will ensure you acquire the right material at the best value for your project.

Leave a Comment

You must be logged in to post a comment.