Aluminium Strip with Film

An aluminium strip with film is a highly versatile material consisting of a thin, flat sheet of aluminum metal coated with a protective or functional film. This innovative combination brings together the inherent advantages of aluminum strip.

Why Choose Aluminium Strip with Film?

The unique structure of aluminum strip with film offers a range of compelling advantages. Firstly, it provides enhanced corrosion resistance.

The protective film acts as a barrier, shielding the aluminum from harsh environments, moisture, and chemicals, thus extending its lifespan significantly.

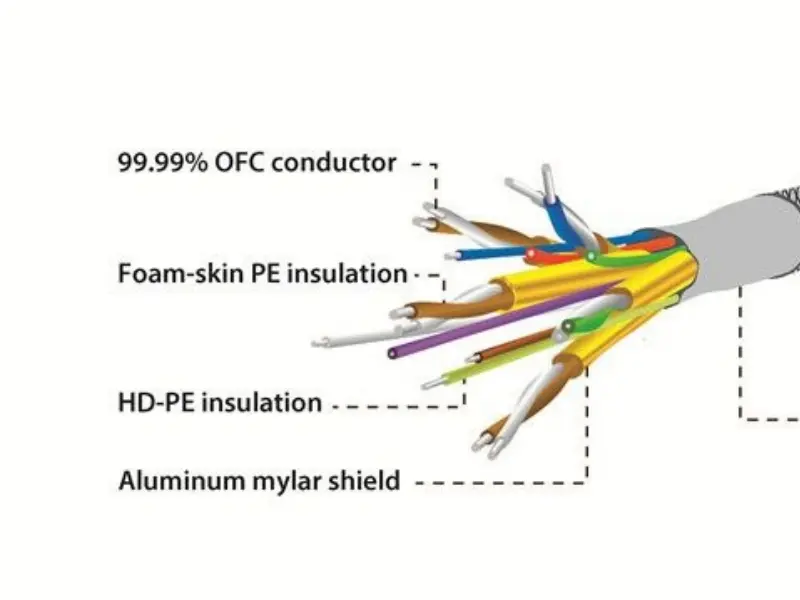

This is vital in outdoor or humid applications. Secondly, depending on the film type, it can offer excellent insulation properties, either electrical or thermal, making it ideal for sensitive applications like electronics or HVAC systems.

This not only makes the product look better but also protects the surface during handling and processing, preventing damage. Lastly, despite the added film, the material remains incredibly lightweight and durable, maintaining aluminum’s ease of handling and forming while offering increased resilience.

These combined benefits make film coated aluminum coil a smart choice for many modern manufacturing needs, delivering both functional and visual advantages.

Manufacturing Process: How It’s Made

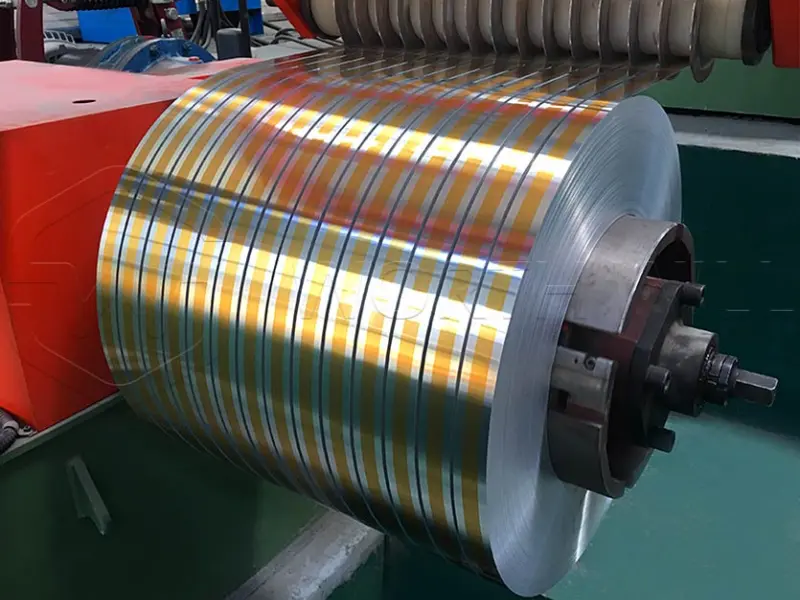

The production of aluminum strip with film involves several precise steps.

The next crucial step is the application of the protective film.

Strict quality control measures are in place throughout the entire process.

This ensures uniform thickness, consistent film adhesion, and overall product integrity. Such rigorous checks guarantee that the final film coated aluminum strip meets high industry standards for performance and reliability.

Types and Specifications: Different Options for Your Needs

Aluminum strip with film comes in various types, each tailored for specific applications. The choice depends on the required alloy, thickness, width, temper, and film type. Understanding these specifications is key to selecting the right material for your project.

Common Aluminum Alloys for Strips:

| Alloy Series | Primary Characteristics | Common Uses |

|---|---|---|

| 1xxx Series | High purity, excellent electrical/thermal conductivity, good corrosion resistance | Electrical, Chemical |

| 3xxx Series | Good strength, excellent formability, corrosion resistance | Packaging, HVAC |

| 5xxx Series | Very good strength, excellent corrosion resistance, especially in marine environments | Automotive, Marine |

| 8xxx Series | Specialized for certain applications like fin stock or battery foil | Heat Exchangers, Batteries |

Typical Physical Specifications (Numerical Types):

| Specification | Range | Unit | Notes |

|---|---|---|---|

| Thickness | 0.05 – 3.0 | mm | Varies by application |

| Width | 10 – 1500 | mm | Customizable for most needs |

| Coil ID | 76, 152, 305, 406, 508 | mm | Inner diameter of the coil |

| Coil OD | Up to 1800 | mm | Outer diameter, depends on length |

| Film Thickness | 0.01 – 0.2 | mm | Depends on protection level |

Common Film Types:

| Film Type | Key Feature | Application Examples |

|---|---|---|

| PVC Film | Good protection, temporary | Surface protection during processing |

| PE Film | General purpose, cost-effective | Temporary surface protection, packaging |

| PET Film | High temperature resistance, electrical insulation | Electronics, heat resistant applications |

| Polyimide Film | Excellent thermal/electrical insulation, high strength | Aerospace, high-performance electronics |

| Self-Adhesive Film | Easy application and removal | Temporary protection, decorative |

Application Areas

The versatility of aluminum strip with film makes it indispensable across numerous industries. Its unique properties allow for innovative solutions in a wide array of products:

- Packaging: Used for food and beverage containers, pharmaceutical packaging, and flexible packaging due to its barrier properties and aesthetic appeal. The film coated aluminum strip protects contents and extends shelf life.

- Construction: Employed in roofing, facade elements, insulation panels, and ductwork.

- Electronics: Crucial for components like capacitors, heat sinks, and cable shielding. The electrical insulation provided by certain films is vital for performance and safety in electronic devices.

- Automotive: Found in vehicle interior trims, heat shields, and battery components. Its lightweight and durable characteristics contribute to fuel efficiency and longevity in modern vehicles.

- HVAC Systems: Widely used for fabricating air ducts and vents, where its ability to maintain integrity in varied temperatures and resist corrosion is paramount for efficient air conditioning and heating.

- Appliances: Used in the manufacture of household appliances for both functional and decorative parts, offering a sleek finish and protection.

- Decorative Purposes: Provides a premium and protected surface for various aesthetic applications, from signage to interior design elements, enhancing visual appeal.

Choosing the Right Aluminum Strip with Film: Factors to Consider

Selecting the correct aluminium strip with film requires careful consideration of several factors to ensure optimal performance and cost-effectiveness for your project.

Project Requirements: What is the primary function? Is it for electrical insulation, heat insulation, corrosion resistance, or a specific aesthetic finish?

Leave a Comment

You must be logged in to post a comment.