Aluminium Sheet Thickness

Understanding Aluminum Sheet Thickness Variations

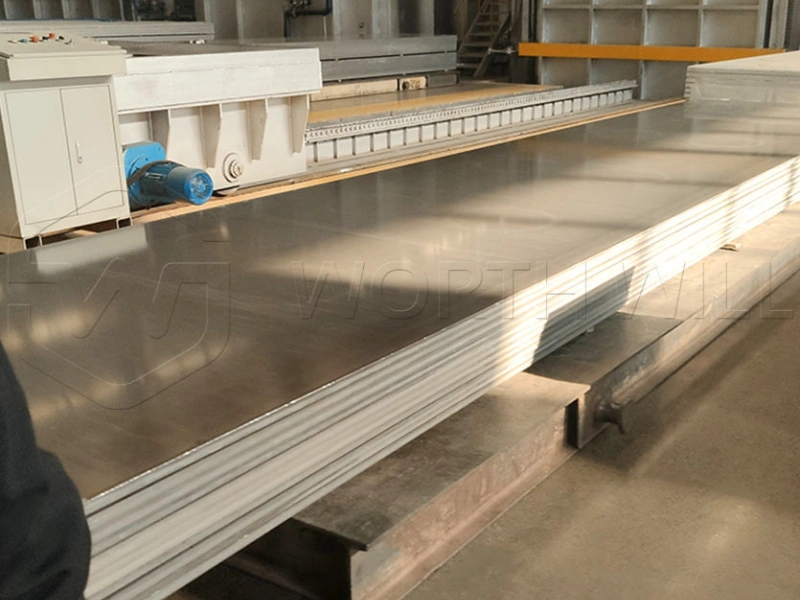

Aluminium sheets are versatile materials used across multiple industries, with thickness being a critical factor in determining their performance and application. This guide explores the essential aspects of aluminium sheet thickness, focusing on key specifications and uses in the Australian market.

Thickness Range and Specifications

Aluminum sheets come in various thicknesses, typically ranging from ultra-thin gauges to substantial plate thicknesses. The thickness directly influences the sheet’s strength, flexibility, and potential applications.

Thickness Measurements

- Gauge measurements

- Millimeter (mm) specifications

- Standard industry dimensions

Common Aluminum Sheet Thickness Types

- Thin Gauge Sheets

- 22 gauge: Approximately 0.75 mm thick

- 30 gauge: Around 0.3 mm thick

- Ideal for lightweight applications

- Standard Thickness Ranges

- 6061 aluminum sheet: Typically 1-25 mm thick

- Architectural and structural applications

- Excellent strength-to-weight ratio

Applications of Aluminum Sheets

Aluminium sheets find extensive use in various sectors:

• Construction and Roofing

- Roof sheeting (typically 0.7-1.2 mm thick)

- Architectural cladding

- Weather-resistant exterior applications

• Manufacturing

- Automotive body panels

- Transportation equipment

- Marine components

• Industrial Engineering

- Machine fabrication

- Equipment manufacturing

- Precision engineering

• Aerospace

- Lightweight structural components

- Advanced engineering applications

Selecting the Right Aluminum Sheet Thickness

When choosing an aluminum sheet, consider:

- Intended application

- Load-bearing requirements

- Environmental conditions

- Weight constraints

Popular Aluminum Alloys

- 3003 Series: General-purpose applications

- 5052 Series: Marine and architectural use

- 6061 Series: Structural and engineering applications

Australian Market Considerations

In the Australian market, aluminum sheet thickness selection depends on:

- Climate conditions

- Industrial requirements

- Specific project specifications

Standard Thickness Recommendations

- Roofing: 0.7-1.2 mm

- Architectural panels: 1-4 mm

- Heavy-duty industrial applications: 6-25 mm

Precision Cutting and Customization

Many suppliers offer:

- Custom cut-to-size services

- Precise thickness measurements

- Various finish options

Conclusion

Understanding aluminum sheet thickness is crucial for selecting the right material for your project. From lightweight 30-gauge sheets to robust 6061 aluminum plates, each thickness offers unique properties suitable for different applications.

Key Takeaways

- Thickness ranges from 0.3 mm to 25 mm

- Multiple alloys for diverse applications

- Critical for performance and durability

When sourcing aluminum sheets in Australia, consult professional suppliers who can provide expert guidance on the most suitable thickness for your specific requirements.

Standard Aluminium Sheet Thickness Chart

| Measurement | Thickness Range | Common Uses |

|---|---|---|

| Thin Gauge | 0.2mm – 1.0mm | Electronics, packaging, decorative panels |

| Medium Gauge | 1.2mm – 3.0mm | Automotive, roofing, signage |

| Heavy Gauge | 3.2mm – 6.0mm | Marine, industrial, structural components |

| Plate | 6.5mm+ | Aerospace, heavy machinery, defense |

Gauge to mm Conversion (Aluminium)

- 30 gauge = 0.3mm

- 26 gauge = 0.45mm

- 22 gauge = 0.8mm

- 18 gauge = 1.2mm

- 14 gauge = 2.0mm

Popular Alloys & Their Typical Thicknesses

1. 3003 Aluminium Sheet

- Common thicknesses: 0.5mm – 6.0mm

- Best for: General fabrication, fuel tanks, chemical equipment

2. 5052 Aluminium Sheet

- Common thicknesses: 0.8mm – 4.0mm

- Best for: Marine applications, vehicle panels, electronic chassis

3. 6061 Aluminium Sheet

- Common thicknesses: 1.6mm – 150mm (plate)

- Best for: Structural frames, aircraft components, high-stress parts

How to Choose the Right Thickness?

Consider these factors:

✔ Load requirements – Thicker sheets for heavy loads

✔ Forming needs – Thinner gauges for complex bends

✔ Corrosion exposure – Thicker = longer lifespan in harsh environments

✔ Weight limitations – Thinner sheets reduce total weight

✔ Budget – Thinner gauges are more cost-effective

Thickness Recommendations by Application

✔ Roofing & Cladding

- Residential: 0.7mm – 1.2mm

- Commercial: 1.5mm – 3.0mm

- Industrial: 3.0mm+

✔ Automotive & Transportation

- Body panels: 1.0mm – 2.0mm

- Structural components: 2.5mm – 6.0mm

✔ Electronics & Appliances

- Enclosures: 0.8mm – 1.5mm

- Heat sinks: 2.0mm – 5.0mm

✔ Marine & Offshore

- Hull plates: 4.0mm – 6.0mm

- Decking: 3.0mm – 5.0mm

FAQs About Aluminium Sheet Thickness

1. What is the thickness of aluminum roofing sheet?

Most residential roofs use 0.7mm-1.2mm, while industrial buildings require 1.5mm-3.0mm.

2. How thick is 6061 aluminum sheet?

Available from 0.5mm (thin sheet) to 150mm (plate), with 1.6mm-6.0mm being most common.

3. What is standard aluminium plate thickness?

Plates typically start at 6.5mm, with common industrial sizes being 10mm, 12mm, 20mm, and 25mm.

4. Is thicker aluminium always better?

Not necessarily – choose based on application requirements to avoid unnecessary weight and cost.

Custom Cutting Services

We provide precision-cut aluminium sheets in:

- Metric sizes (mm)

- Imperial gauges

- Specialty thicknesses upon request

Why Choose Our Aluminium Sheets?

✅ Accurate thickness tolerance (±0.05mm)

✅ All major alloys available

✅ Competitive pricing for all thickness ranges

✅ Global shipping with protective packaging

Contact us today for thickness recommendations or a quote!

SEO Keywords Naturally Included:

- aluminium sheet thickness

- 6061 aluminum sheet thickness

- 22 gauge aluminum sheet

- aluminium roofing sheet thickness

- standard aluminium plate thickness

- thin aluminium sheet

- thick aluminum plate

- gauge to mm aluminium

This guide provides clear, actionable information while optimizing for search engines with proper keyword placement and structure.

Leave a Comment

You must be logged in to post a comment.