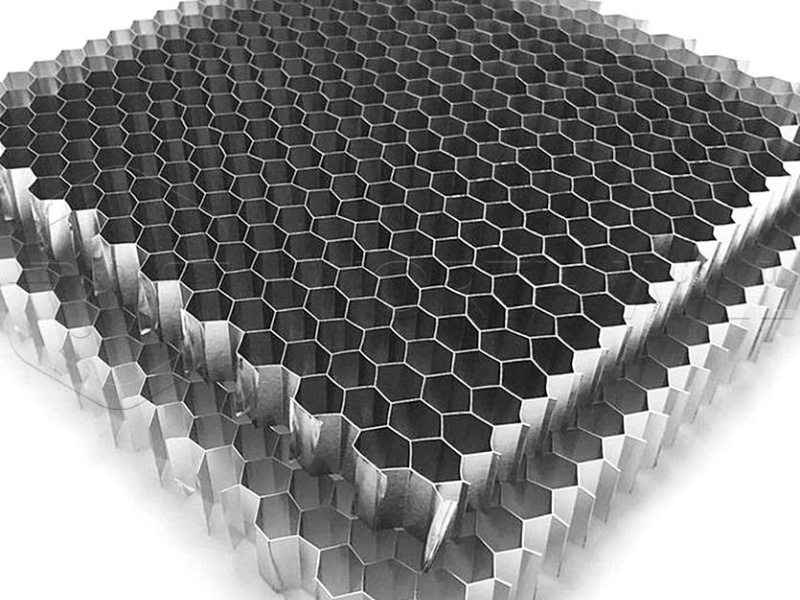

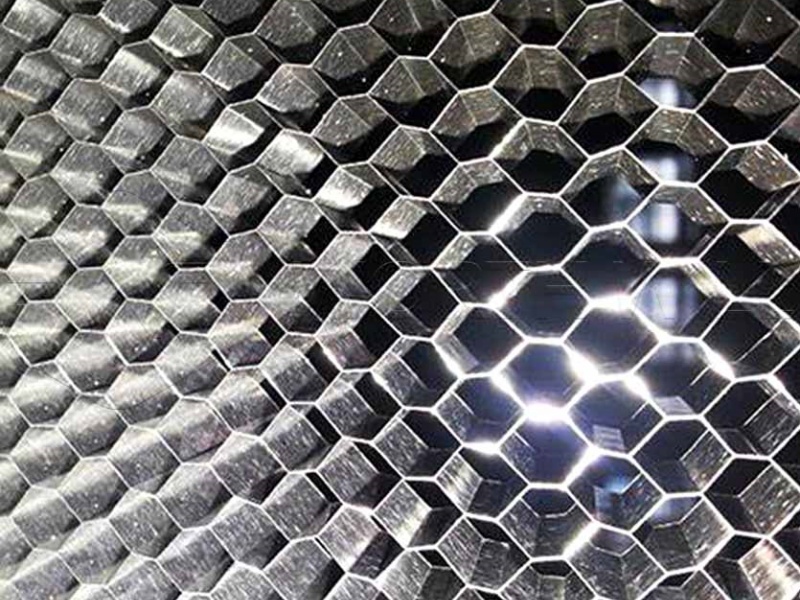

Aluminium honeycomb core is a lightweight and strong material widely used in industries such as aerospace, construction, transportation, and furniture. Made from thin aluminum foil bonded into a hexagonal pattern, it offers excellent mechanical performance and durability.

Specification

The aluminium honeycomb core can be customized in terms of cell size, foil thickness, and panel dimensions. Below is a general specification table:

| Property | Details |

|---|---|

| Core Alloy | 3003 / 5052 aluminium |

| Cell Size | 3mm – 25mm |

| Foil Thickness | 0.04mm – 0.1mm |

| Density | 20 – 120 kg/m³ |

| Core Thickness | 6mm – 100mm |

| Standard Panel Size | 1220mm × 2440mm (custom sizes available) |

| Surface Treatment | Bare, chromated, primer coated |

Types of Aluminum Honeycomb Cores

| Parameter | 3003 Alloy | 5052 Alloy | Commercial Grade |

|---|---|---|---|

| Cell Size | 3mm, 6mm, 10mm | 3mm, 6mm, 10mm | 6mm, 10mm, 15mm |

| Density | 40-80 kg/m³ | 50-100 kg/m³ | 30-60 kg/m³ |

| Compression Strength | 1.2-2.5 MPa | 1.5-3.0 MPa | 0.8-2.0 MPa |

| Max Temperature | 150°C | 200°C | 120°C |

| Thickness | 6-50mm | 6-50mm | 10-100 |

1. 3003 Aluminum Honeycomb Core

- Properties:

- Moderate strength

- Excellent corrosion resistance

- Good formability

- Applications:

- Architectural panels

- Interior partitions

- Exhibition displays

2. 5052 Aluminum Honeycomb Core

- Properties:

- Higher strength than 3003

- Superior marine corrosion resistance

- Better fatigue resistance

- Applications:

- Marine bulkheads

- Aircraft flooring

- High-end transportation

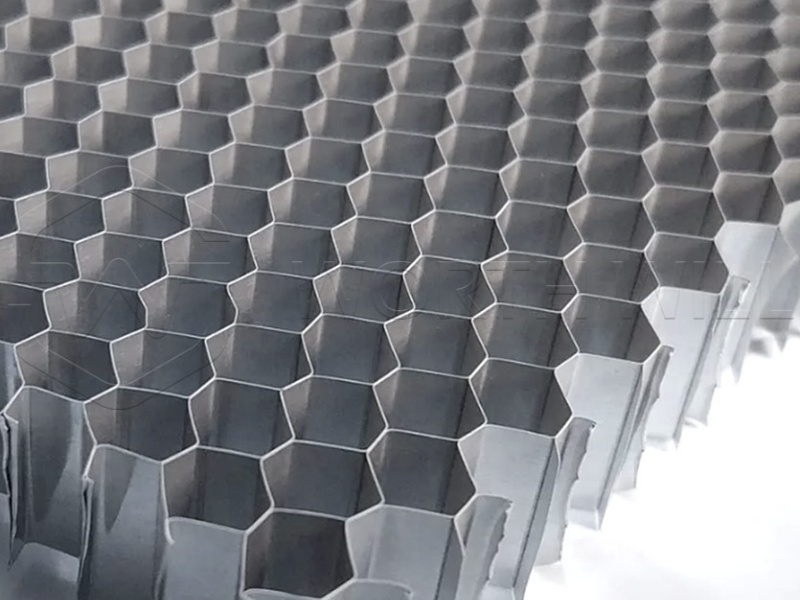

3. Commercial Grade Honeycomb Core

- Cost-effective solution for industrial uses

- Typical applications:

- Door cores

- Industrial work surfaces

- Packaging inserts

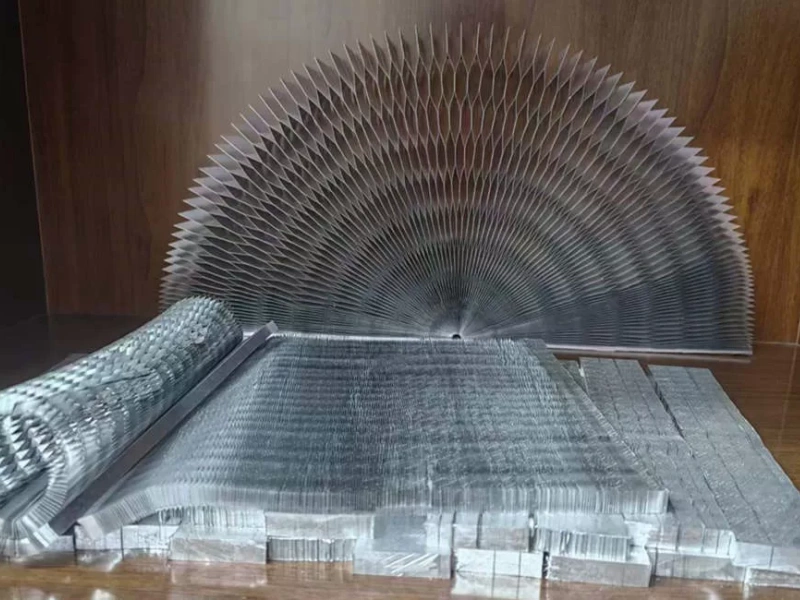

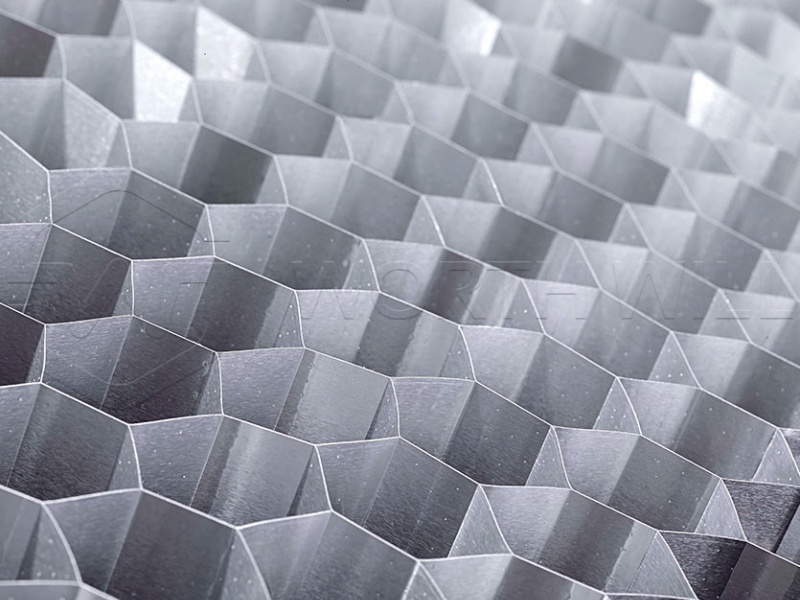

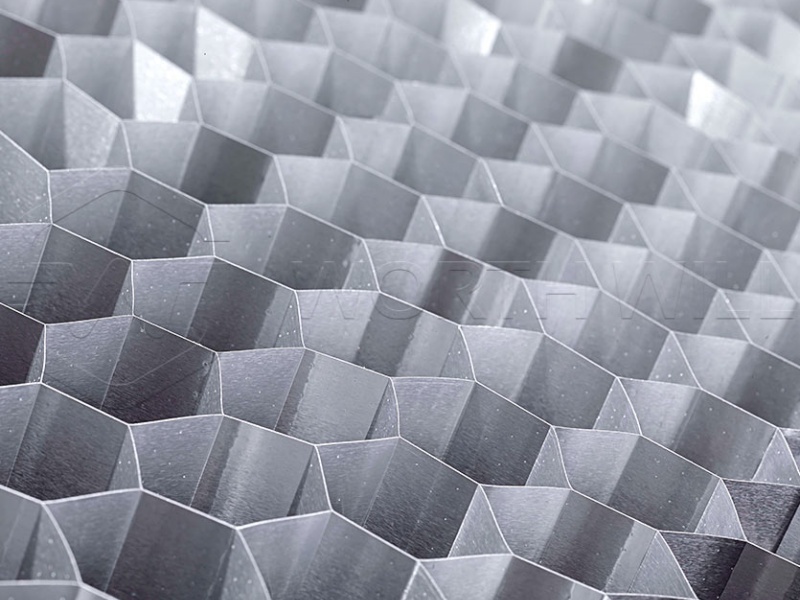

Aluminum Honeycomb Core Manufacturing Process

- Expansion Method

- Aluminum foil sheets printed with adhesive lines

- Stacked and expanded to form hexagonal cells

- Corrugation Method

- Foil pre-corrugated before bonding

- Produces more uniform cell structure

Types

We offer two main types of aluminum honeycomb core:

- 3003 Aluminum Honeycomb Panel: Known for its excellent corrosion resistance and weldability, this type is ideal for applications where exposure to harsh environments is a concern.

- 5052 Aluminum Honeycomb Core: This type offers higher strength and durability, making it suitable for applications where high performance is required.

Aluminium Honeycomb Core Material

Our aluminum honeycomb core is made from high-quality aluminum alloys, carefully selected for their strength, corrosion resistance, and durability. The honeycomb structure is created through a process of expansion and stabilization, resulting in a lightweight yet rigid material.

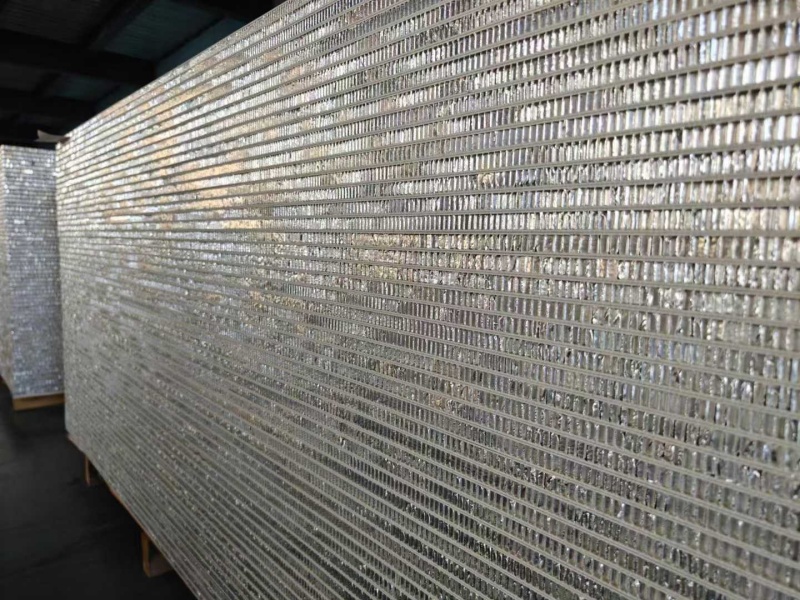

Aluminium Honeycomb Core Manufacturer

As a leading manufacturer of aluminum honeycomb core, we pride ourselves on our ability to produce high-quality materials that meet the exacting requirements of our customers. Our state-of-the-art facilities and experienced team ensure that every product is manufactured to the highest standards.

Aluminum Honeycomb Core—Commercial Grade

Our commercial-grade aluminum honeycomb core is designed for a wide range of applications, from construction to industrial manufacturing. It is available in a variety of cell sizes and densities to suit specific requirements.

Aluminum Honeycomb Core, Custom Honeycomb

We also offer custom honeycomb solutions, tailored to meet the specific needs of our customers. Whether you require a specific cell size, density, or material, we can work with you to create a product that meets your exact requirements.

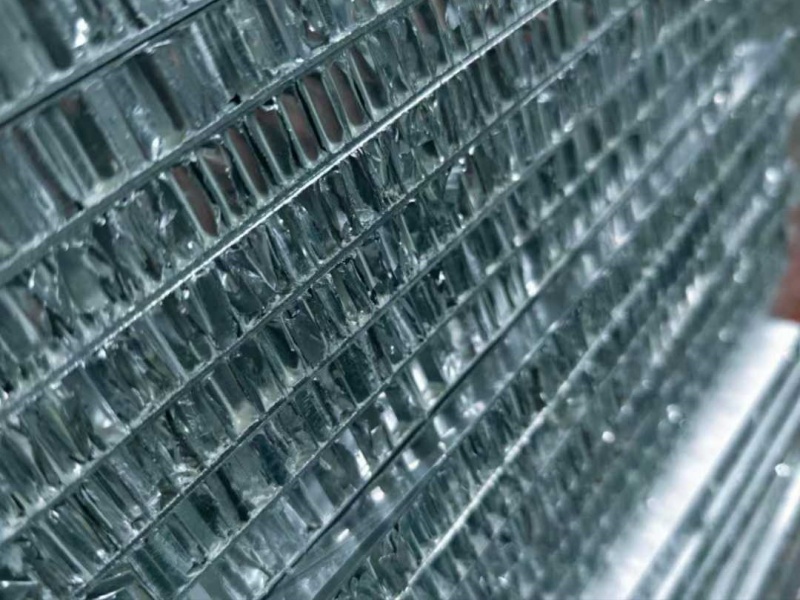

Aluminum Honeycomb Panels

Our aluminum honeycomb panels are composed of two thin aluminum skins bonded to a honeycomb core. This construction provides exceptional strength, stability, and resistance to fatigue.

Applications

The versatility of aluminum honeycomb core makes it suitable for a wide range of applications, including:

- Aerospace: aircraft structures, satellite components

- Construction: building facades, roofing, flooring

- Industrial: machinery, equipment, and tooling

- Automotive: body panels, chassis components

- Marine: boat hulls, decking

Packaging

To ensure safe transportation and storage, our aluminum honeycomb core products are carefully packaged in protective wrapping and crates. We can also accommodate custom packaging requirements.

In conclusion, our aluminum honeycomb core is a high-performance material that offers a unique combination of strength, stability, and lightweight properties. With a range of types and specifications available, we can meet the needs of various industries and applications. Contact us today to learn more about our products and how they can benefit your business.

What is Aluminum Honeycomb Core?

Aluminium honeycomb core is a lightweight, high-strength material with a hexagonal cell structure, offering:

Ultra-low density (30-100 kg/m³)

Exceptional strength-to-weight ratio

Superior energy absorption

Customizable cell configurations

Widely used in aerospace, transportation, and construction industries.

Packaging Options

- Standard: Wooden crates with foam protection

- Export: Seaworthy pallets with waterproof wrapping

- Custom: Pre-cut kits with numbered labeling

Frequently Asked Questions

Q: What’s the difference between 3003 and 5052 honeycomb cores?

A: 5052 offers 20% higher strength and better saltwater resistance, while 3003 is more cost-effective for indoor use.

Q: Can honeycomb cores be curved?

A: Yes, minimum radius = 10x panel thickness (e.g., 10mm panel → 100mm radius).

Q: How does weight compare to solid aluminum?

A: 80% lighter with comparable stiffness in bending applications.

Q: Are custom cell shapes available?

A: Yes – hexagonal, rectangular, and over-expanded configurations.

Ordering Information

- Select alloy and cell size

- Specify thickness and dimensions

- Request quote (24-hour response)

- Production lead time: 7-15 days

Minimum Order:

- 10m² for custom specifications

- 50m² for bulk discounts

Conclusion

Aluminium honeycomb core delivers unmatched performance where lightweight strength is critical. From cutting-edge aerospace to innovative architecture, this material enables breakthroughs in design and efficiency.

Contact us today for samples and project-specific engineering support!