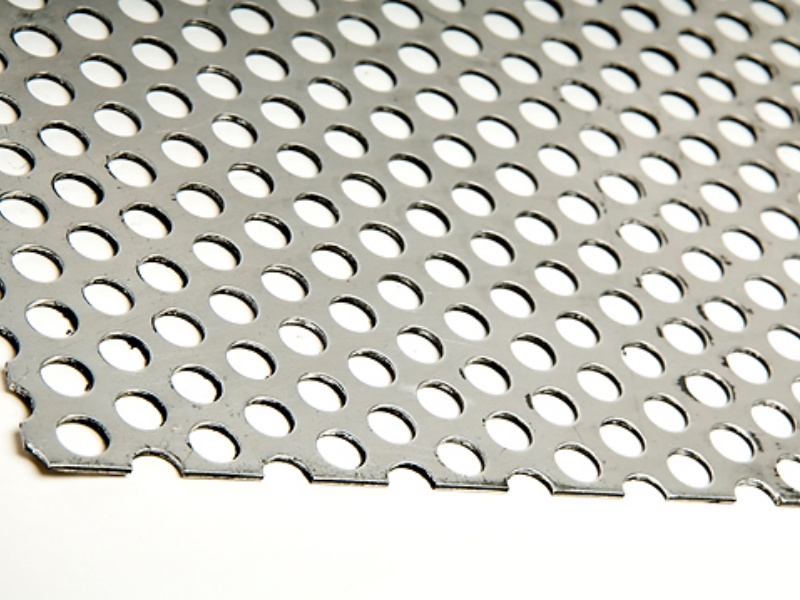

Perforated aluminum panels are sheets of aluminum with holes of various shapes and sizes punched through the surface. These panels are lightweight, durable, and used for both functional and decorative purposes.

Basic Specifications

- Material: 1000, 3000, and 5000 series aluminum alloys

- Thickness: 0.5 mm to 5.0 mm

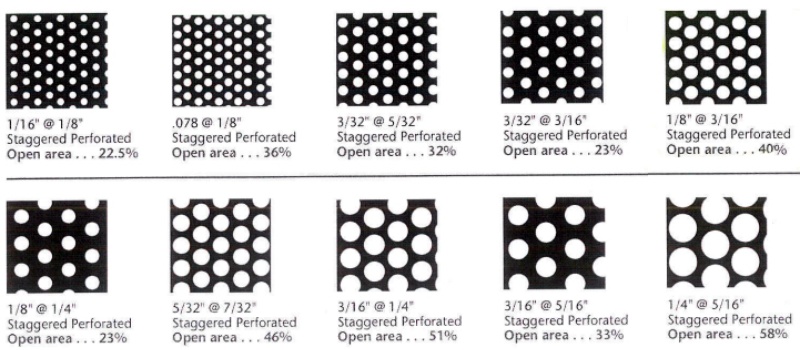

- Hole patterns: Round, square, slotted, hexagonal, custom

- Hole sizes: 1 mm to 20 mm

- Sheet sizes: 1000 x 2000 mm, 1220 x 2440 mm, and custom sizes

- Surface finish: Mill finish, anodized, powder coated, PVDF

Types

There are several types of perforated aluminum panels to meet different requirements:

- Perforated aluminum sheet metal panels: For architectural and industrial use

- Perforated aluminum corrugated sheet: Combines strength and ventilation

- Decorative perforated panels: Ideal for facades and interiors

- Perforated acoustic panels: Used for sound absorption

- Perforated aluminum ceiling panels: Lightweight and modern ceiling solution

Pricing Factors

- Hole pattern complexity (simple round vs. custom designs)

- Material thickness (0.5mm starts at 20/m2;3mmat20/m2;3mmat50/m²)

- Finish (anodizing adds 20-30% cost)

Application

Perforated aluminum panels are used in a wide range of industries due to their versatility and aesthetic appeal:

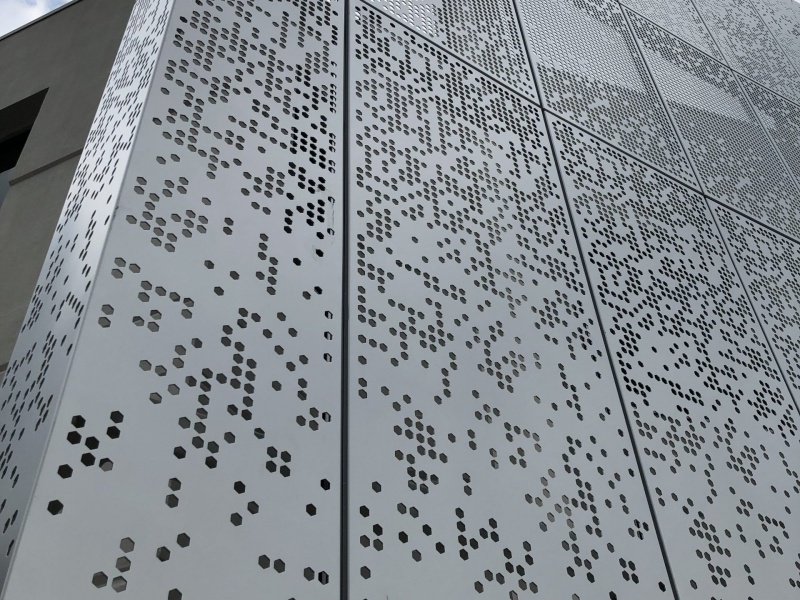

- Architectural cladding and facades

- Ceiling and wall panels

- Sunshades and privacy screens

- Ventilation and airflow systems

- Machine guards and filters

- Furniture and decorative design

- Soundproofing and acoustic treatment

Advantages vs. Disadvantages

✅ Pros:

50% lighter than steel perforated sheets

Naturally corrosion-resistant

Easy to cut/bend (CNC or hand tools)

❌ Cons:

Higher cost than fiberglass mesh

Limited structural strength vs. solid metal

Perforated vs. Mesh Metal

Feature Perforated Mesh

Manufacturing Punch-pressed Woven/welded

Strength Higher rigidity More flexible

Hole Precision Exact sizing Variable

Cost $$$ $$

What is perforated aluminum sheet used for?

Perforated aluminum sheets are commonly used for architectural facades, sunshades, ceiling tiles, acoustic panels, and filtration systems. The punched holes allow for air and light passage while providing strength and modern style.

What are the disadvantages of perforated metal?

While perforated aluminum is lightweight and functional, it has a few limitations:

- Reduced structural strength compared to solid metal

- More expensive than plain aluminum sheets

- May require special tooling for fabrication

- Needs precise design to prevent weakening of material

What is the difference between perforated and mesh?

Perforated metal has holes punched in a solid sheet in a controlled pattern. Mesh, on the other hand, is woven or welded with openings between wires. Perforated panels offer more design options and are generally stronger.

Is perforated metal expensive?

Perforated aluminum is generally more costly than plain sheets due to the punching process and finishing. However, its design value, functionality, and low maintenance often make it a cost-effective long-term solution.

Perforated Sheets Metal – Stainless Steel, Aluminum, Copper

Perforated metal sheets are available in various materials, including:

- Aluminum: Lightweight, corrosion-resistant

- Stainless steel: Strong and rust-proof

- Copper: Decorative and durable, often used in interiors

Packaging

To protect the perforated panels during delivery:

- Plastic film or paper wrapping

- Foam interlayer between sheets

- Wooden pallet or crate packaging

- Custom labeling and packaging options available

Why Choose Us?

- Experienced perforated metals manufacturer

- Custom shapes, hole sizes, and patterns

- Fast lead times and global shipping

- Affordable pricing and reliable quality

Whether you’re designing a modern building facade or seeking an industrial ventilation solution, perforated aluminum panels offer the ideal mix of form and function. Contact us now for details, free samples, or a custom quote.

FAQ

Q: What’s the minimum bending radius?

A: 2x panel thickness (e.g., 1mm sheet = 2mm radius).

Q: Can panels be powder-coated colors?

A: Yes – RAL colors available (extra 15-25% cost).

Q: How to clean perforated aluminum?

A: Mild soap + water; avoid abrasive tools.

Q: Are custom hole patterns possible?

A: Yes – provide vector files for precision punching.