Different Types of Aluminium Cladding

Aluminium cladding is a popular choice for building exteriors due to its durability, lightweight properties, and aesthetic appeal. It serves as a protective layer, shielding buildings from environmental elements while also enhancing their appearance. With various types of aluminium cladding available, each offering unique benefits, it’s essential to understand the differences to make the best choice for your project.

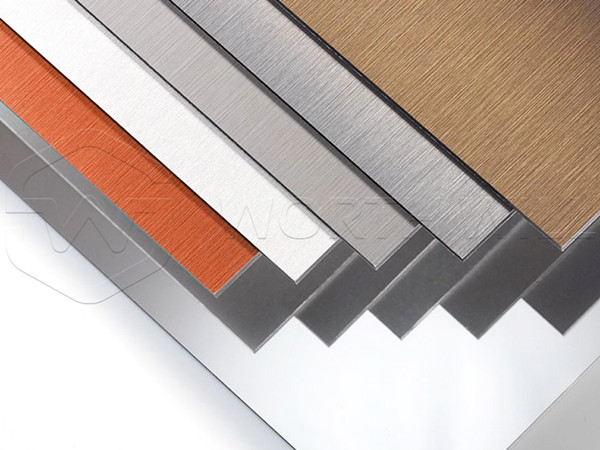

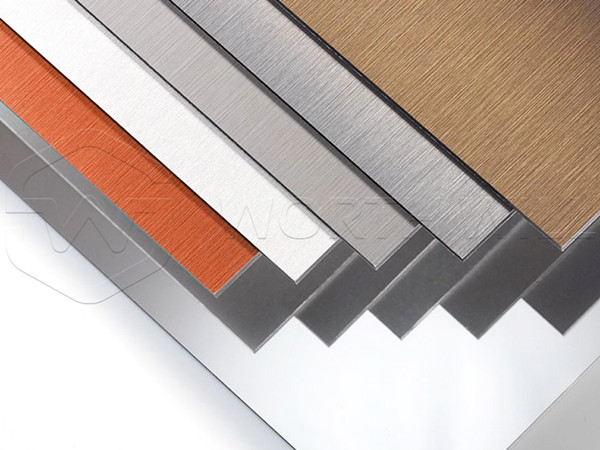

1. Aluminium Composite Panel (ACP)

What It Is:

Aluminum Composite Panel (ACP) consists of two thin layers of aluminum sheets bonded to a non-aluminum core, typically made of polyethylene or mineral-filled cores for fire resistance.

Advantages:

- Lightweight and Strong: ACP is lightweight yet strong, making it easy to install and ideal for high-rise buildings.

- Versatile Design Options: ACP panels are available in a wide range of colors, finishes, and textures, allowing for creative architectural designs.

- Weather and Corrosion Resistant: The aluminum surface provides excellent resistance to weather and corrosion, ensuring long-term durability.

Applications:

- Building facades

- Signage and advertising panels

- Interior wall cladding

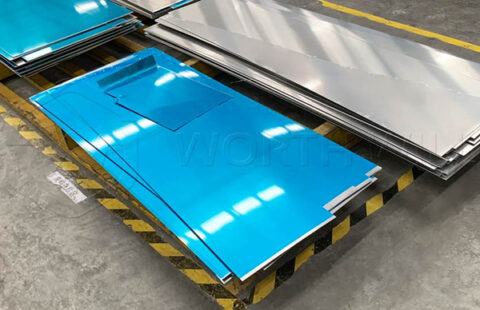

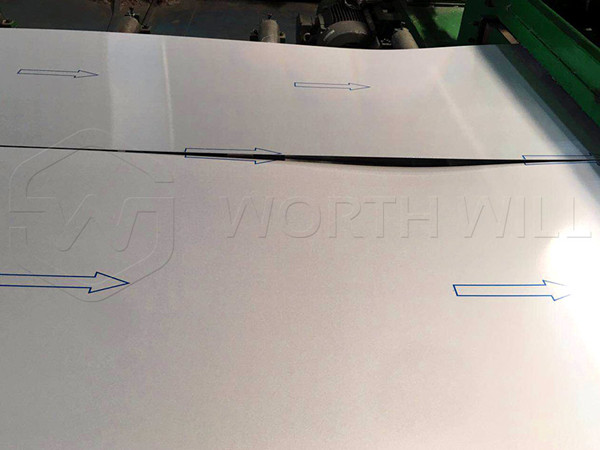

2. Solid Aluminium Cladding

What It Is:

Solid aluminum cladding is made from a single layer of aluminum, offering high strength and rigidity. It is available in various thicknesses, depending on the structural requirements.

Advantages:

- High Strength and Durability: Solid aluminum cladding is incredibly strong and resistant to impact, making it suitable for areas prone to wear and tear.

- Fire Resistant: Unlike ACP, solid aluminum panels do not contain combustible materials, providing better fire resistance.

- Sleek and Modern Appearance: Solid aluminum panels offer a sleek, modern look, often used in contemporary architectural designs.

Applications:

- Public and commercial buildings

- Architectural facades

- Industrial facilities

3. Perforated Aluminium Cladding

What It Is:

Perforated aluminum cladding features patterns of holes or perforations, allowing for unique designs and functional benefits such as ventilation and light filtration.

Advantages:

- Aesthetic Flexibility: Perforated cladding offers endless design possibilities, with customizable patterns that can add visual interest to any building.

- Ventilation and Light Control: The perforations allow for natural ventilation and light diffusion, making it ideal for environments requiring airflow and controlled lighting.

- Lightweight and Easy to Install: Perforated aluminum panels are lightweight and can be easily installed, reducing construction time and costs.

Applications:

- Architectural facades

- Sunshades and privacy screens

- Interior partitions and ceilings

4. Aluminum Honeycomb Panel Cladding

What It Is:

Aluminum honeycomb panels are made from two thin layers of aluminum bonded to a honeycomb core, offering a high strength-to-weight ratio and excellent rigidity.

Advantages:

- Superior Strength-to-Weight Ratio: The honeycomb structure provides high strength while keeping the weight low, making it suitable for large panels.

- Thermal and Acoustic Insulation: The honeycomb core offers excellent insulation properties, reducing heat transfer and noise pollution.

- Corrosion and Weather Resistant: Honeycomb panels are highly resistant to corrosion and weathering, ensuring long-lasting performance in various environments.

Applications:

- High-rise buildings

- Curtain walls

- Commercial interiors and exteriors

5. Anodized Aluminum Cladding

What It Is:

Anodized aluminum cladding undergoes an electrochemical process that enhances the natural oxide layer on the aluminum surface, providing increased durability and aesthetic options.

Advantages:

- Enhanced Durability: The anodizing process makes the aluminum surface harder and more resistant to wear, corrosion, and UV radiation.

- Wide Range of Colors and Finishes: Anodized cladding is available in various colors and finishes, including matte, gloss, and metallic, providing design flexibility.

- Eco-Friendly: Anodized aluminum is environmentally friendly, with no harmful chemicals involved in the process, and it is fully recyclable.

Applications:

- Exterior building facades

- Architectural details

- Decorative elements in interiors

6. Powder-Coated Aluminum Cladding

What It Is:

Powder-coated aluminum cladding involves applying a protective powder coating to the aluminum surface, which is then baked to create a durable, smooth finish.

Advantages:

- Durable and Scratch-Resistant: The powder coating creates a tough, scratch-resistant surface that can withstand harsh conditions.

- Variety of Colors and Textures: Powder coating allows for a wide range of color options and finishes, from matte to glossy and even textured surfaces.

- Low Maintenance: The coating provides a low-maintenance surface that resists fading, chipping, and corrosion over time.

Applications:

- Residential and commercial buildings

- Outdoor structures and installations

- Architectural facades

Understanding the Different Types of Aluminium Cladding: A Comprehensive Guide

Aluminum cladding offers a versatile and durable solution for a wide range of applications, from commercial buildings to residential projects. Whether you need the lightweight flexibility of ACP, the strength of solid aluminium, or the unique design possibilities of perforated panels, understanding the different types of aluminium cladding can help you make the best choice for your project.

Each type of aluminum cladding has its own advantages and ideal applications, so consider your specific needs, including design, durability, and environmental factors, before making a decision. With the right selection, aluminum cladding can enhance both the appearance and performance of your building.

Ready to explore the best aluminum cladding options for your next project? Contact us today to learn more about our products and how we can help you achieve your design and performance goals.

Leave a Comment

You must be logged in to post a comment.