5052 Aluminium Plate

- Home

- 5052 Aluminium Plate

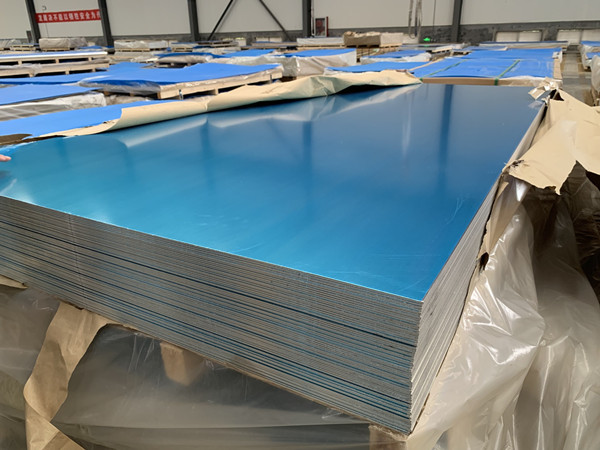

5052 aluminium plate is an AL-Mg alloy aluminium plate. Magnesium is the main alloying element in the 5052 alloy aluminium plate. It’s the most widely used anti-rust aluminium.

5052 aluminum plate

This alloy has high strength, especially fatigue resistance: plasticity and corrosion resistance high toughness, no heat treatment strengthening, good plasticity when semi-cold work hardening, low plasticity when cold work hardening, good corrosion resistance, good weld-ability, poor machine ability, and can be polished.

-

Free Sample

-

Customized Service

Direct Factory

Specification

| Alloy | 5052 |

| Temper | O-H112 |

| Thickness | 0.2-400mm |

| Width | 200-2650mm |

| Length | Under 11900mm |

| Application | alumina plates, silos, automotive aluminum plates, molds, etc. |

Chemical Composition

Aluminium Al: Balance

Silicon Si: ≤0.25

Copper Cu: ≤0.10

Magnesium Mg: 2.2~2.8

Zinc Zn: ≤0.10

Manganese Mn: ≤0.10

Chromium Cr: 0.15~0.35

Iron Fe: ≤0.40

Note: single: ≤0.05; total: ≤0.15

Process Performance

- Form-ability

A: The alloy has good process plasticity in hot state. The forging and die forging temperature is 420~475°C, and the hot deformation with a deformation rate of 80% is carried out within this temperature range.

B: The cold stamping performance is related to the alloy state. For example, the cold stamping performance in the annealed (O) state is good.

- Welding Performance

A: The alloy has good performance in gas welding, arc welding, resistance welding, spot welding and seam welding, and crystallization cracks tend to appear in two argon arc welding. The brazing performance is still good, but the soft soldering performance is poor.

B: The strength and plasticity of the weld are high, and the strength of the weld reaches 90% to 95% of the strength of the base metal.

However, the airtightness of the weld is not high. It’s recommended to adopt 5A03 alloy as the solder, which can improve its airtightness and eliminate the tendency of cracks.

- Machining Performance

The cutting performance of the alloy is not good in the annealed state, but the cutting performance is improved in the cold work hardened state.

5052 Aluminium Plate Application

- Automobile panels: engine outer panels, bus trunk panels, aluminium panels for fuel tanks.

- Building materials: high-end curtain wall panels, shutters, trolley boxes, door panels/door handles, signs, silos.

- Mechanical appliances: 3C products, computer brackets, precision machining, etc.

- Anti-slip aluminium checker plate: aluminium checker plate requires the thickness of the aluminium plate to be more than 1.2mm thick.

5052 Aluminium Plate Performance

1. Good corrosion resistance

2. Excellent weldability

3. Good cold workability

4. Medium strength