3mm Thick Perforated Aluminium Sheet

Unveiling the Versatility of a Precisely Crafted Metal Sheet

In the vast world of construction, design, and manufacturing, the demand for materials that offer both functionality and aesthetic appeal is ever-growing. Among these, the 3mm thick perforated aluminium sheet stands out as a prime example of versatility meeting performance. If you’re seeking a robust yet lightweight material that allows for air circulation, light diffusion, and visual intrigue, understanding the unique qualities of a 3mm thick perforated aluminium sheet is key.

A perforated aluminium sheet is essentially a flat aluminium sheet that has been mechanically punched with a series of holes or patterns. What makes the 3mm thick variant particularly special is its optimal balance. This thickness provides significant structural integrity and durability, making it far more rigid than thinner gauges, while still retaining the inherent lightweight advantage of aluminium. This balance opens up a vast array of applications, making the 3mm thick perforated aluminium sheet a highly sought-after material across various industries.

What is Perforated Aluminium? And Why 3mm?

The process of creating perforated aluminium involves precision machinery that punches various hole shapes (round, square, slotted, hexagonal, etc.) into a solid aluminium sheet. This not only transforms its appearance but also imbues it with a range of functional benefits.

The choice of 3mm thickness is often considered a “sweet spot” for many applications for several reasons:

- Enhanced Rigidity: A 3mm thick perforated aluminium sheet offers superior stiffness and flatness compared to thinner sheets (e.g., 1mm or 2mm). This reduces the likelihood of warping or bending, even over larger spans.

- Increased Durability: This thickness provides excellent resistance to impact and general wear and tear, making it suitable for high-traffic areas or applications where robustness is critical.

- Structural Capability: While still lightweight, 3mm allows the perforated aluminium to contribute more significantly to the structural integrity of an assembly.

- Workability: Despite its strength, 3mm aluminium remains relatively easy to cut, bend, and form using standard fabrication techniques, offering good flexibility in design.

- Optimal Balance: It strikes an ideal balance between weight, cost, and strength, making it a cost-effective choice for many projects that require a durable and lightweight metal.

For these reasons, the 3mm thick perforated aluminium sheet is a preferred material for those who need a sturdy yet adaptable aluminium sheet.

Key Characteristics and Advantages

Beyond its specific thickness, the general properties of perforated aluminium contribute to its widespread use:

- Lightweight: Aluminium is inherently light, which reduces structural loads and eases installation.

- Excellent Corrosion Resistance: Aluminium forms a natural oxide layer that protects it from rust and corrosion, making perforated aluminium suitable for both indoor and outdoor applications, even in harsh environments.

- Ventilation and Airflow: The perforations allow for excellent air circulation, making it ideal for enclosures, grilles, and protective screens.

- Light Diffusion and Privacy: Perforated panels can diffuse harsh light, reduce glare, and offer a degree of privacy without completely blocking views.

- Sound Absorption: The holes can help to absorb sound waves, making perforated aluminium useful in acoustic panels and noise control applications.

- Aesthetic Appeal: Available in a wide variety of hole patterns and sizes, perforated aluminium offers a modern, high-tech, and often sophisticated look.

- Easy to Fabricate: It can be easily cut, bent, welded, and finished to meet specific design requirements.

- Sustainable: Aluminium is 100% recyclable, making perforated aluminium an environmentally friendly material choice.

Manufacturing Process

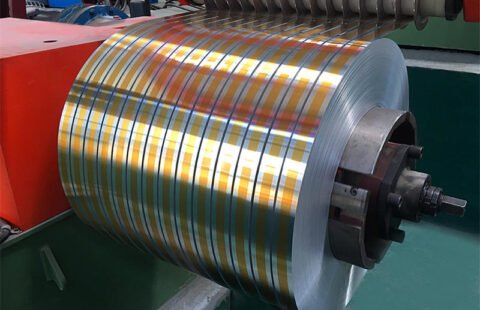

The creation of a 3mm thick perforated aluminium sheet involves specialized machinery. Large coils or flat sheets of raw aluminium are fed into a punching press. This press is equipped with dies that precisely punch out the desired hole patterns. The material then passes through rollers to ensure flatness. The precision of the machinery allows for consistent hole size, spacing, and pattern repetition, ensuring a high-quality finished product.

3mm Thick Perforated Aluminium Sheet: Specifications at a Glance

| Specification | Description & Common Values | Impact on Performance & Application |

|---|---|---|

| Classification | Perforated Sheet: Defined by having holes punched through its surface. | Allows for light, air, and sound passage; provides specific aesthetic patterns. |

| Thickness | 3.0 mm (0.118 inches): Primary specified thickness. | Provides significant rigidity, durability, good impact resistance, and structural contribution. |

| Alloy | 3003: Good strength, excellent corrosion resistance, most common. 5052: Higher strength, excellent corrosion resistance, good 1050: Good formability, general purpose. | 3003 and 5052 are very common for structural perforated applications. |

| Packaging | Flat Sheets: Cut to size, stacked on pallets, often with protective film. Coils: Large rolls for continuous processing. | Flat Sheets: Ready for direct use or further fabrication. Coils: For high-volume industrial use. Protective film: Guards against scratches during transit/handling. |

| Hole Pattern | Round: Most common. Square: Clean, modern look. Slotted: Rectangular holes. Hexagonal: Honeycomb-like. Decorative/Custom: Unique shapes. | Defines aesthetic, open area percentage, and specific functional requirements |

| Hole Size | Common range: 3mm to 20mm+ (diameter for round holes). Expressed as the diameter (for round) or side length (for square/hex). | Influences open area, light transmission, airflow, and visual opacity. |

| Pitch | The distance from the center of one hole to the center of the next. Expressed as P | Determines the density of the pattern and the percentage of open area. |

| Open Area Percentage | The total area of the holes as a percentage of the total sheet area. Typically ranges from 20% to 60%. | Crucial for performance related to airflow, light, sound, and screening. |

| Margin/Border | Can be standard (manufacturer’s discretion) or custom. | Provides strength, allows for easy attachment/framing |

| Standard Sheet Size | 1000x2000mm, 1220x2440mm (4×8 ft), 1500x3000mm. Custom sizes available. | Affects material efficiency, ease of handling, and specific project dimensions. |

| Surface Finish | Mill Finish: Raw, un-treated aluminium. Anodized: Adds corrosion resistance and color. Powder Coated: Durable, colored finish. | Mill Finish Anodized/Powder Coated: |

Diverse Applications of 3mm Thick Perforated Aluminium Sheets

The robust yet lightweight nature of a 3mm thick perforated aluminium sheet makes it an ideal choice for a vast array of applications across numerous industries:

- Architectural Facades and Cladding: Creates striking, modern building exteriors that allow light and air while providing shade and a unique visual texture.

- Sunshades and Brise-Soleil: Effectively controls sunlight and glare on buildings, reducing energy consumption for cooling.

- Security Screens and Balustrade Infills: Offers robust protection while maintaining visibility and airflow.

- Acoustic Panels: Used in ceilings, walls, and enclosures to absorb sound in public spaces, offices, and studios.

- HVAC Grilles and Vents: Durable and corrosion-resistant components for air conditioning and ventilation systems.

- Walkways, Platforms, and Stair Treads: Provides a safe, non-slip surface, especially with specific hole patterns like diamond or raised types.

- Filtration and Screening: Used in various industrial filters, strainers, and separation equipment due to precise hole sizes.

- Machine Guards and Enclosures: Protects machinery and personnel while allowing for ventilation and visual inspection.

- Retail Displays and Shelving: Offers a modern, clean look for product displays in stores.

- Furniture Components: Used in outdoor furniture, benches, and decorative panels for its durability and aesthetic.

- Vehicle Components: For grilles, interior panels, and airflow management in automotive, marine, and railway applications.

Conclusion

The 3mm thick perforated aluminium sheet is more than just a metal panel with holes; it’s a precisely engineered material offering a compelling blend of strength, lightweight properties, and aesthetic versatility. Its ability to manage light, air, and sound, combined with its inherent durability and corrosion resistance, makes it an invaluable asset across countless sectors. By understanding its specific classifications, precise thickness, and broad range of applications, you can harness the full potential of this exceptional aluminium sheet to create innovative, functional, and visually stunning solutions for your next project.

Leave a Comment

You must be logged in to post a comment.