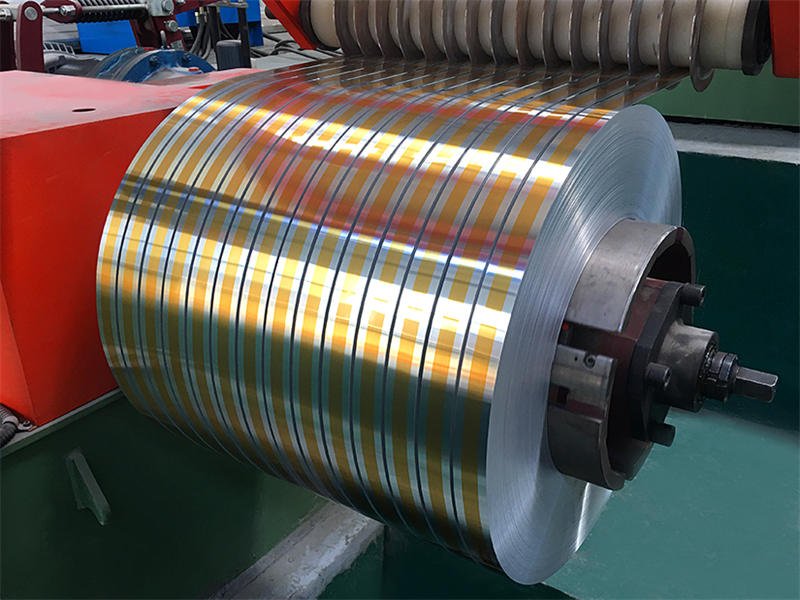

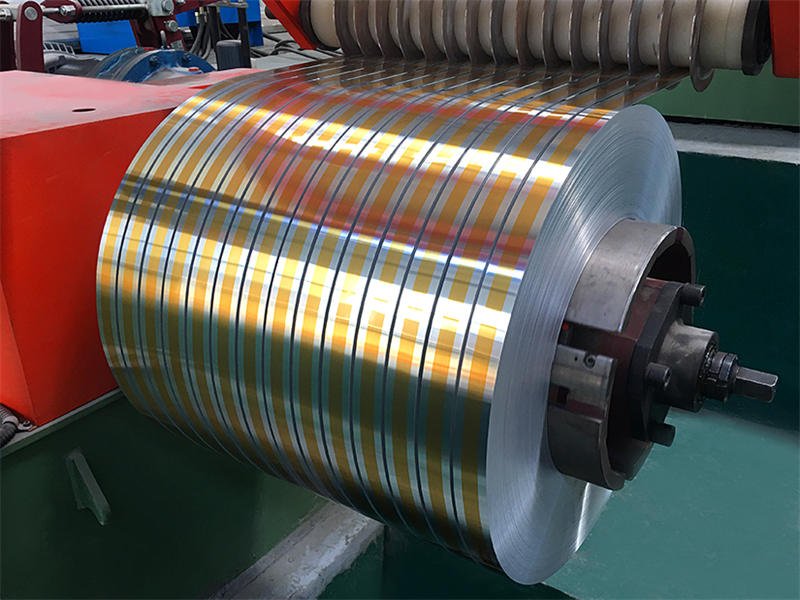

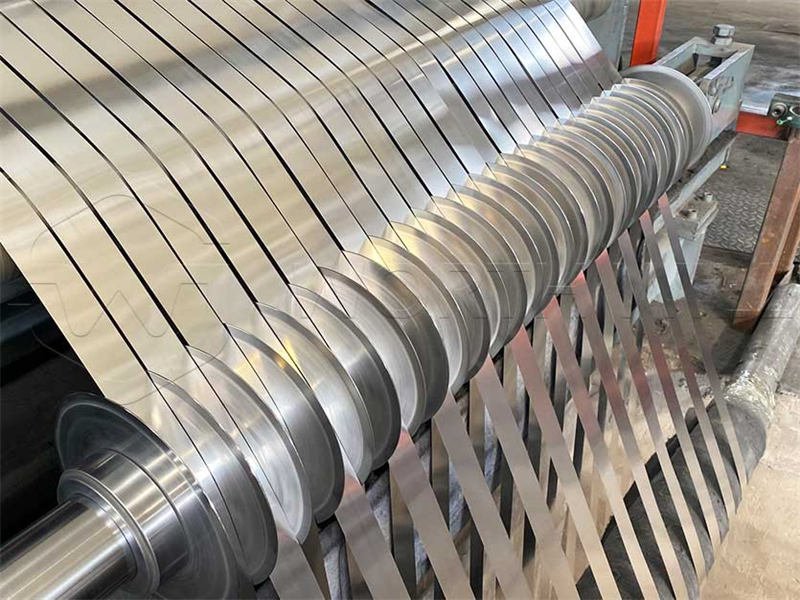

1mm, 2mm, 3mm, 4mm, 5mm, 6mm Aluminium Strips

What Are Aluminium Strips?

Aluminium strips (1mm, 2mm, 3mm, 4mm, 5mm, 6mm) are flat-rolled aluminum products used across industries for structural and functional applications. These precision strips combine aluminum’s lightweight properties with excellent strength and formability.

Key Benefits:

Lightweight yet durable

Excellent corrosion resistance

Good thermal/electrical conductivity

Easy to cut and form

Recyclable and eco-friendly

Classification by Application

| Type | Thickness Range | Primary Use |

|---|---|---|

| Electrical Strips | 1mm-3mm | Busbars, transformers |

| Construction Strips | 2mm-5mm | Cladding, flashing |

| Industrial Strips | 3mm-6mm | Machinery parts, frames |

| Packaging Strips | 1mm-2mm | Can ends, closures |

Thickness Specifications

Detailed comparison of common thicknesses:

| Thickness | Weight (kg/m²) | Tensile Strength | Bending Radius |

|---|---|---|---|

| 1mm | 2.7 | 80-150 MPa | 1.5x thickness |

| 2mm | 5.4 | 80-150 MPa | 2x thickness |

| 3mm | 8.1 | 100-200 MPa | 3x thickness |

| 4mm | 10.8 | 100-250 MPa | 4x thickness |

| 5mm | 13.5 | 120-300 MPa | 5x thickness |

| 6mm | 16.2 | 150-350 MPa | 6x thickness |

Alloy Options

Common alloys for different thicknesses:

| Alloy | 1mm-2mm Uses | 3mm-4mm Uses | 5mm-6mm Uses |

|---|---|---|---|

| 1050 | Food packaging | Decorative trims | – |

| 3003 | HVAC components | Tank linings | Marine structures |

| 5052 | Electronic housings | Vehicle panels | Truck bodies |

| 6061 | – | Structural frames | Heavy equipment |

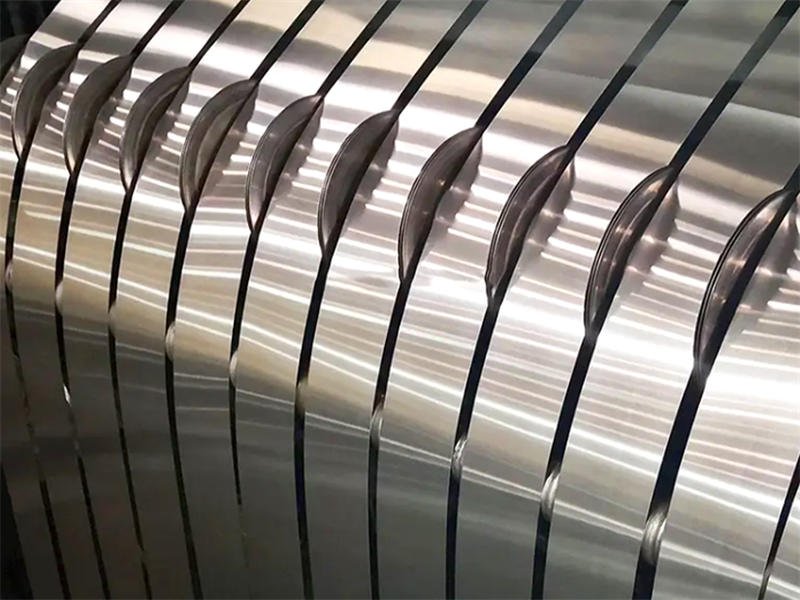

Packaging Standards

Standard packaging options:

Wooden crates (for 4mm-6mm strips)

Coil form (1mm-3mm, up to 2000kg)

Protective edge covers

Waterproof wrapping

Custom cut lengths available

Top 5 Application Industries

- Electrical Industry

- Busbar conductors

- Transformer windings

- Electrical enclosures

- Construction Sector

- Roof flashing (1mm-2mm)

- Curtain wall supports (3mm-4mm)

- Structural brackets (5mm-6mm)

- Transportation

- Aircraft interior panels

- Truck trailer linings

- Railway carriage parts

- Manufacturing

- Machine guards

- Conveyor components

- Equipment frames

- Consumer Goods

- Appliance trim

- Furniture components

- DIY project materials

Selection Guide by Thickness

1mm Strips

- Ideal for: Flexible applications, lightweight packaging

- Max width: 500mm

- Finish options: Mill, brushed, coated

2mm Strips

- Ideal for: General fabrication, electrical uses

- Max width: 800mm

- Can be perforated

3mm Strips

- Ideal for: Structural applications

- Max width: 1200mm

- Weldable grades available

4mm Strips

- Ideal for: Heavy-duty construction

- Max width: 1500mm

- Can be anodized

5mm-6mm Strips

- Ideal for: Industrial load-bearing uses

- Max width: 2000mm

- Often supplied in T6 temper

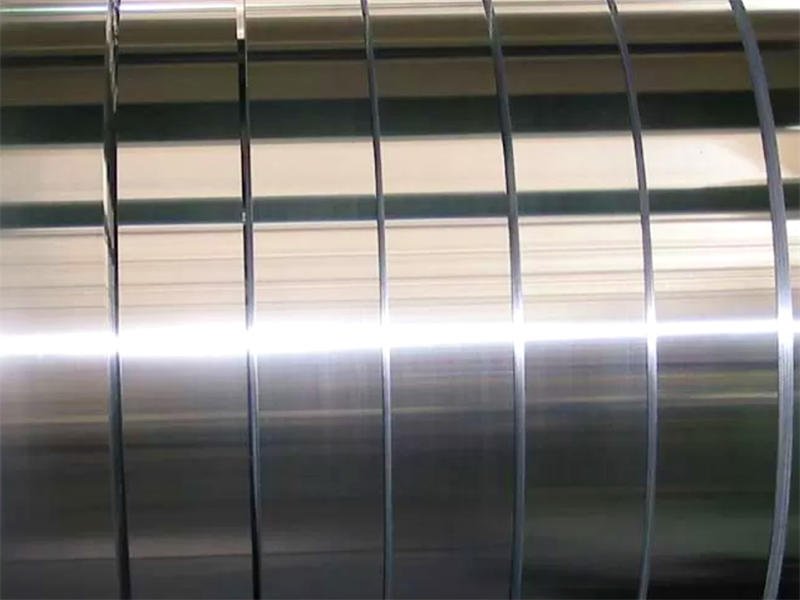

Quality Control Measures

Reputable manufacturers provide:

Thickness tolerance ±0.05mm

Edge condition certification

Surface finish inspection

Mechanical testing reports

Chemical composition analysis

Global Supply Options

Major production regions:

• China – Cost-effective volumes

• Europe – Precision-grade strips

• North America – Quick-turn services

Cost Considerations

Price factors include:

- Alloy grade

- Thickness precision

- Order quantity

- Surface treatment

- Packaging requirements

Note: 3mm is typically the most economical thickness

Maintenance Tips

For optimal performance:

• Clean with pH-neutral solutions

• Store in dry conditions

• Avoid contact with dissimilar metals

• Inspect for corrosion annually

• Reapply protective coatings as needed

Conclusion

Choosing the right aluminium strip thickness (1mm-6mm) depends on your specific mechanical requirements and application needs. From delicate 1mm packaging strips to robust 6mm structural components, aluminum offers versatile solutions across industries.

Key selection criteria:

Verify alloy matches application demands

Confirm thickness tolerances

Consider surface finish options

Evaluate supplier’s cutting capabilities

Request material certifications

Whether you need the flexibility of 1mm strips or the strength of 6mm material, understanding these specifications ensures optimal performance in your projects.

Leave a Comment

You must be logged in to post a comment.