1/8 Perforated Aluminum Sheet

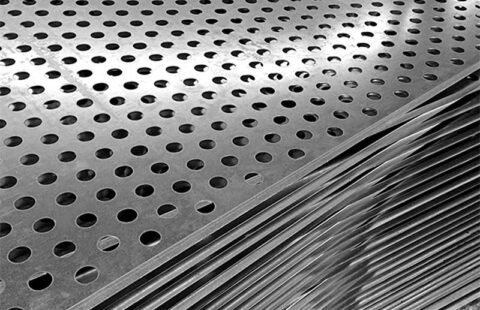

A 1/8 perforated aluminum sheet is a lightweight yet strong metal sheet with holes of 1/8 inch (3.175 mm) diameter. These sheets are widely used for ventilation, filtration, decorative designs, and industrial purposes.

Aluminum’s corrosion resistance and easy fabrication make it ideal for both indoor and outdoor use.

Types and Specifications of 1/8 Perforated Aluminum Sheet

1/8 perforated aluminum sheet can be customized with various hole sizes, patterns, and finishes, making it adaptable to diverse needs. Here’s a table outlining common specifications:

| Feature | Description | Common Specifications for 1/8″ Sheet |

|---|---|---|

| Material Alloy | Specific aluminum alloy providing different properties. | 3003-H14 (good formability), 5052-H32 (better strength), 6061-T6 (structural strength) |

| Sheet Thickness | The base thickness of the aluminum sheet. | 1/8 inch (0.125″ or 3.175 mm) |

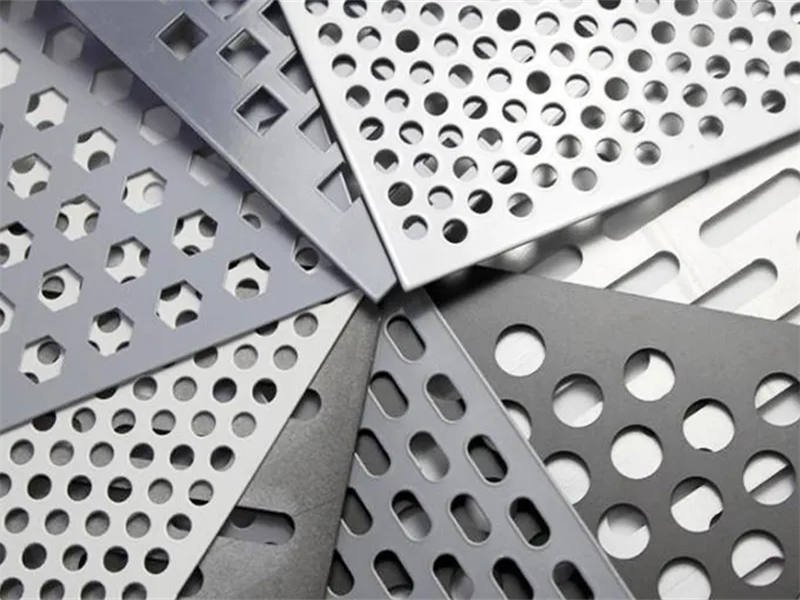

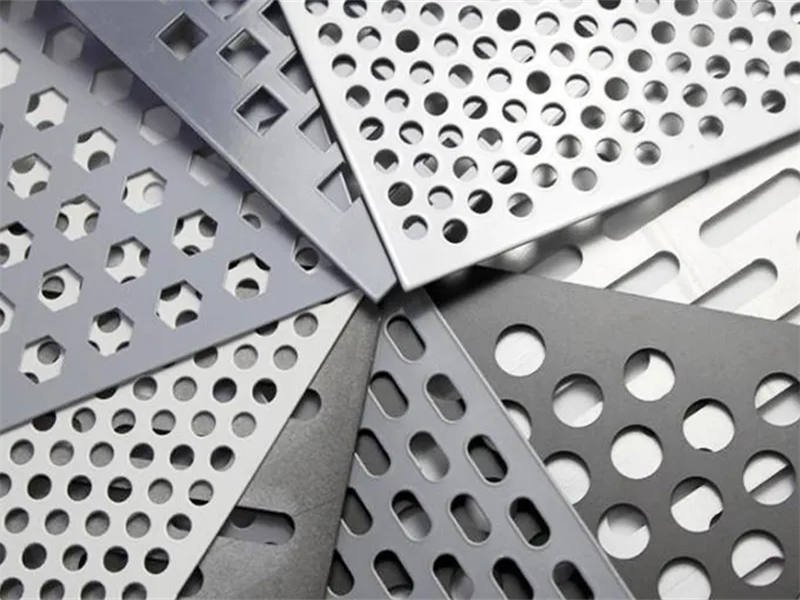

| Hole Shape | The design of the holes. | Round, Square, Slotted, Hexagonal, Decorative |

| Hole Size (Diameter) | The size of the individual perforations. | 1/16″, 1/8″, 3/16″, 1/4″, 3/8″, 1/2″, 3/4″, 1″ (and larger) |

| Hole Pattern | Arrangement of holes on the sheet. | Staggered (60-degree, most common), Straight (90-degree), Custom |

| Center-to-Center Spacing | Distance from the center of one hole to the next. | Varies based on hole size and desired open area |

| Open Area (%) | The percentage of the sheet that is open space (holes). | Typically ranges from 20% to 60%, depending on hole size and pattern |

| Margin/Border | Unperforated edges around the sheet. | Standard (e.g., 1/2″ or 1″ on all sides) or Custom |

| Standard Sheet Size | Common dimensions in which sheets are supplied. | 4′ x 8′, 4′ x 10′, 5′ x 8′, 5′ x 10′ (custom sizes available) |

| Surface Finish | Treatment applied after perforation. | Mill Finish (raw), Anodized (various colors), Powder Coated (various colors), Brushed |

2. Specifications of 1/8 Perforated Aluminum Sheet

| Specification | Details |

|---|---|

| Hole Diameter | 1/8 inch (3.175 mm) |

| Hole Shape | Round (most common), square, slotted |

| Open Area | 20% – 40% depending on pitch |

| Sheet Thickness | 0.5 mm – 6 mm |

| Sheet Size | 4′ x 8′, 4′ x 10′, custom sizes |

| Alloy Options | 1100, 3003, 5052 |

| Finish | Mill finish, anodized, powder coated |

| Pattern | Straight row, staggered |

3. Alloy Options and Properties

| Alloy | Strength | Corrosion Resistance | Weldability | Applications |

|---|---|---|---|---|

| 1100 | Low | High | Excellent | Decorative panels, signs |

| 3003 | Medium | Very High | Good | HVAC, enclosures |

| 5052 | High | Excellent | Excellent | Marine, outdoor projects |

4. Benefits of Using 1/8 Perforated Aluminum Sheet

- Lightweight but strong – Easy to handle and install

- Corrosion-resistant – Ideal for outdoor and marine environments

- Good ventilation – Allows air and light to pass through

- Easy to cut and fabricate – Suitable for custom designs

- Aesthetic appeal – Can be polished, painted, or anodized

5. Common Patterns and Hole Layouts

| Pattern | Description | Best Use |

|---|---|---|

| Straight row | Holes aligned in rows and columns | Decorative cladding |

| Staggered | Holes offset for strength and airflow | Filtration, guards |

| Custom design | Logo or special shapes | Branding, art |

Fabrication Capabilities

| Process | Compatibility | Notes |

|---|---|---|

| Cutting | Excellent | Shear, laser, waterjet |

| Bending | Good | Minimum radius 3/8″ |

| Welding | Fair | TIG recommended |

| Powder Coating | Excellent | Requires pretreatment |

Packaging Options

| Package Type | Protection Method | Best For |

|---|---|---|

| Flat Pack | Cardboard sandwich | Small orders |

| Wooden Crate | Edge guards + foam | Large sheets |

| Bulk Shipment | Steel-strapped pallets | 50+ sheets |

Price Factors (2025)

| Factor | Price Impact |

|---|---|

| Hole Size | Smaller = +20% |

| Open Area | Higher % = +15% |

| Alloy | 5052 = +25% vs 3003 |

| Quantity | 50+ sheets: 10% discount |

| Finish | Mill (standard) vs painted (+30%) |

6. Applications of 1/8 Perforated Aluminum Sheet

Industrial Uses

- Machinery guards and safety covers

- Ventilation panels and HVAC grilles

- Filtration systems

Architectural Uses

- Building facades

- Sunshades and privacy screens

- Acoustic panels

Decorative Uses

- Signboards and displays

- Furniture panels

- Interior wall designs

7. Thickness and Size Chart

| Thickness (mm) | Approx. Weight (kg/m²) | Common Applications |

|---|---|---|

| 0.5 mm | 1.35 | Decorative panels |

| 1.0 mm | 2.70 | Interior partitions |

| 2.0 mm | 5.40 | Protective guards |

| 3.0 mm | 8.10 | Exterior cladding |

| 6.0 mm | 16.20 | Heavy-duty flooring |

8. Choosing the Right Perforated Aluminum Sheet

When selecting a 1/8 perforated aluminum sheet, consider:

- Environment – Indoor, outdoor, or marine exposure

- Load requirements – Thicker sheets for heavy-duty use

- Aesthetic needs – Finish, color, and pattern design

- Budget – Alloy choice can affect cost and durability

Leave a Comment

You must be logged in to post a comment.