1/4 Perforated Aluminum Sheet

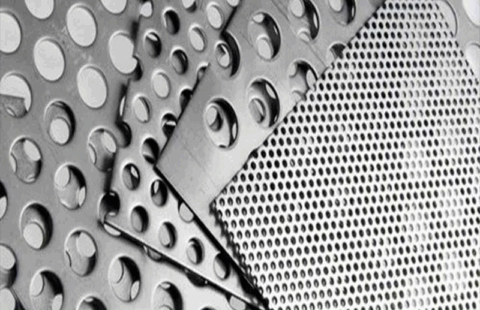

The 1/4 perforated aluminum sheet is a widely used material in many industries. This sheet features holes that are 1/4 inch in diameter, providing an excellent balance of strength and ventilation. It is commonly used for applications that require both durability and airflow, such as in construction, decoration, and industrial settings.

Classification of 1/4 Perforated Aluminum Sheet

Perforated aluminum sheets can be classified based on hole size, sheet thickness, and alloy type. The 1/4 perforated pattern is commonly used because it provides good airflow while maintaining strength.

| Classification Type | Details |

|---|---|

| Hole Size | 1/4 inch (6.35 mm) |

| Hole Shape | Round, square, or decorative |

| Open Area | 20% – 40% depending on pattern |

| Alloy Options | 1100, 3003, 5052, 6061 |

| Surface Finish | Mill finish, anodized, or powder-coated |

Thickness Options

The thickness of perforated aluminum sheets affects durability and flexibility. Thicker sheets are better for heavy-duty use, while thinner sheets are more suitable for decorative and lightweight projects.

| Thickness (inches) | Thickness (mm) | Typical Use |

|---|---|---|

| 0.032″ | 0.8 mm | Indoor decorative panels |

| 0.063″ | 1.6 mm | Ventilation, cladding |

| 0.125″ | 3.2 mm | Security panels, machinery |

| 0.25″ | 6.35 mm | Heavy-duty construction |

Alloy Choices for 1/4 Perforated Aluminum Sheet

The alloy you choose will determine the sheet’s performance in different conditions.

| Alloy | Properties | Best Use |

|---|---|---|

| 1100 | Soft, corrosion-resistant | Decorative projects, signage |

| 3003 | Good strength, corrosion resistance | HVAC, building panels |

| 5052 | High corrosion resistance | Marine, outdoor projects |

| 6061 | High strength, machinable | Structural and industrial use |

Packaging and Supply

To ensure safety during transport, 1/4 perforated aluminum sheets are usually packed with protective film, palletized, and wrapped for export. Customized sizes and packaging are available for bulk orders.

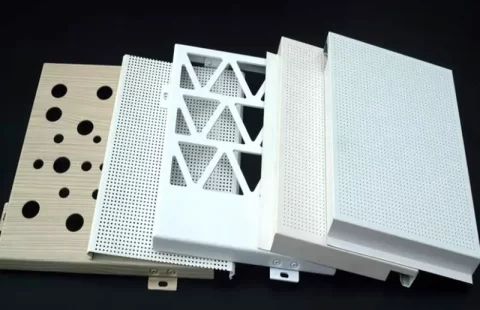

Types and Specifications of 1/4 Perforated Aluminum Sheets

1/4 perforated aluminum sheets come in various gauges, thickness, and patterns. Below is a table showing the common types and dimensions:

| Type | Thickness (mm) | Hole Diameter (inches) | Hole Pattern | Open Area (%) | Typical Use |

|---|---|---|---|---|---|

| Light Gauge | 0.5 – 0.8 | 1/4 | Round | 20-30 | Decorative panels, interior screens |

| Medium Gauge | 0.9 – 1.5 | 1/4 | Square | 30-40 | Ventilation grilles, sunshades |

| Heavy Gauge | 1.6 – 2.5 | 1/4 | Hexagonal | 40-50 | Industrial guards, machine covers |

This data helps you choose the right sheet based on thickness, hole pattern, and application needs.

How to Use 1/4 Perforated Aluminum Sheet

Using 1/4 perforated aluminum sheets correctly involves the following steps:

- Measure and Cut:

- Measure the required area carefully.

- Use tin snips or power tools designed for aluminum sheets to cut.

- Surface Preparation:

- Clean and prepare the surface where the sheet will be installed.

- Apply primer if painting is required.

- Installation:

- Attach the sheet with screws, bolts, or welding depending on the application.

- For ventilation, allow space between the sheet and the surface.

- Finishing:

- Paint or coat the sheet to increase corrosion resistance.

- Use powder coating for outdoor uses.

Applications

- Building facades and cladding

- Acoustic panels for noise reduction

- Sunshade panels to reduce heat and glare

- Ventilation covers and air filters

- Safety guards on machinery

- Decorative partitions and panels

- Outdoor signage and lighting fixtures

These uses make the 1/4 perforated aluminum sheet a versatile material in industrial and decorative projects.

Benefits of 1/4 Perforated Aluminum Sheet

Choosing 1/4 perforated aluminum sheets offers these advantages:

- Strong and Lightweight: Aluminum is durable, yet easy to handle.

- Good Ventilation: Holes allow airflow and cooling.

- Rust Resistant: Aluminum naturally resists corrosion.

- Aesthetic Appeal: The perforated pattern adds a modern look.

- Customizable: Available in different gauges and hole patterns.

- Low Maintenance: Easy to clean and maintain over time.

Maintenance Tips for 1/4 Perforated Aluminum Sheets

To keep your perforated aluminum sheet in top condition:

- Clean regularly with mild detergent and water.

- Avoid abrasive materials that can scratch the surface.

- Inspect fasteners and tighten as needed.

- Repaint or recoat if exposed to harsh weather.

Choosing the Right Size and Type

When selecting a 1/4 perforated aluminum sheet, consider the following factors:

Alloy type depending on environment (indoor vs. outdoor)

Required hole pattern (round, square, or custom)

Desired open area percentage for airflow or light passage

Thickness based on strength requirements

Leave a Comment

You must be logged in to post a comment.